Laser measuring device for narrow slit detection and positioning and measuring method thereof

A technology of laser measurement and laser triangulation, applied in the field of laser vision system, can solve the problems of difficult to accurately locate spatial position, difficult to detect, difficult to achieve, and achieve the effect of improving recognition ability, improving structure and function, and improving contrast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

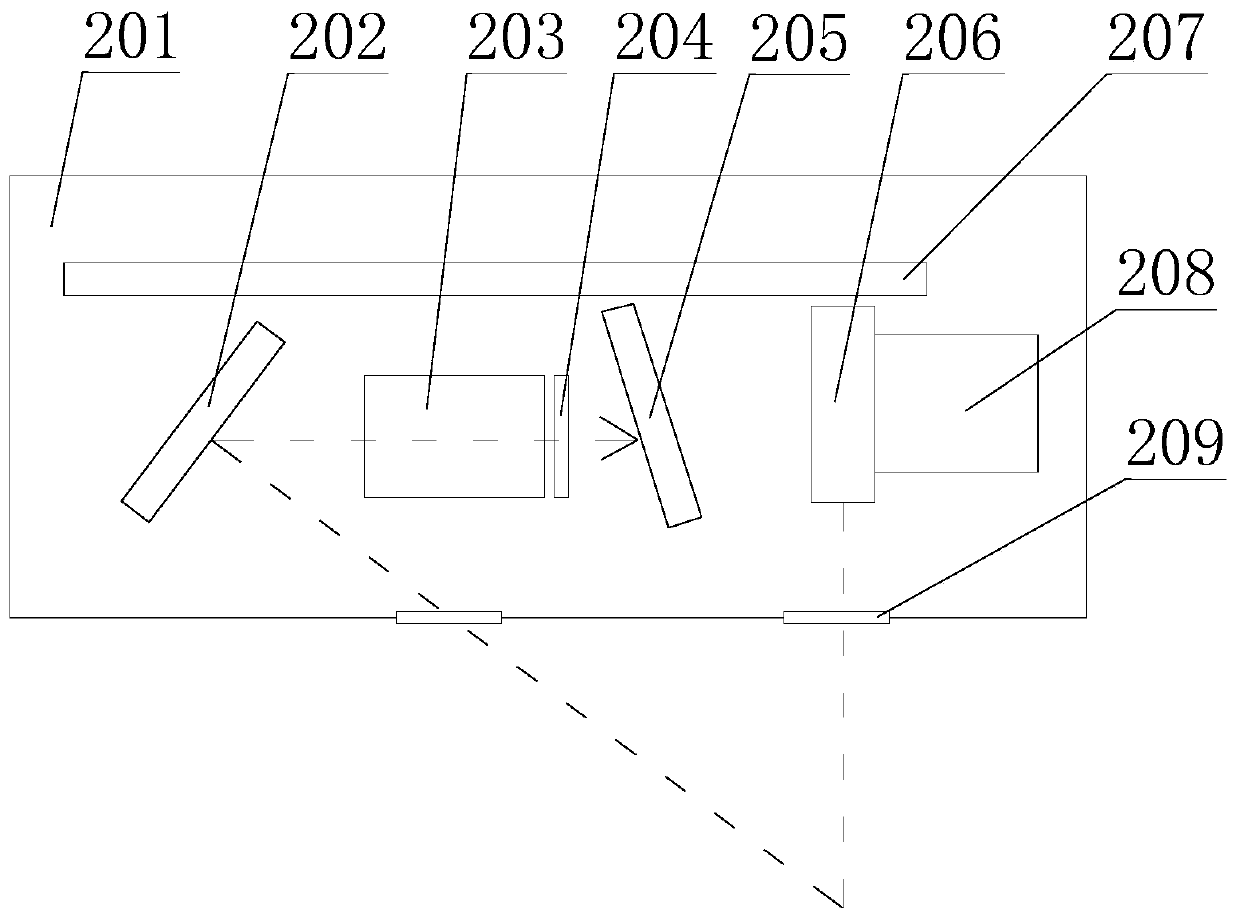

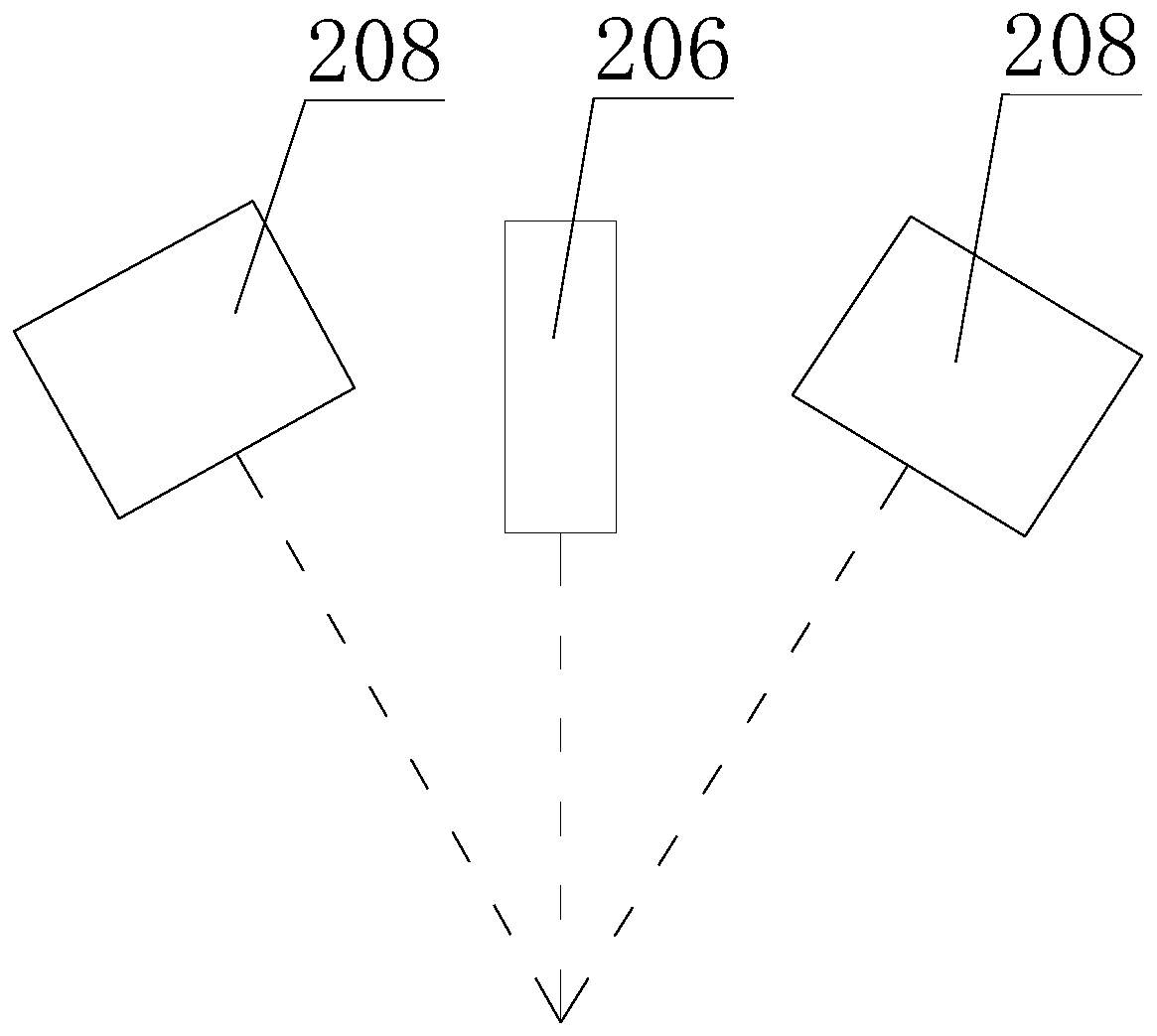

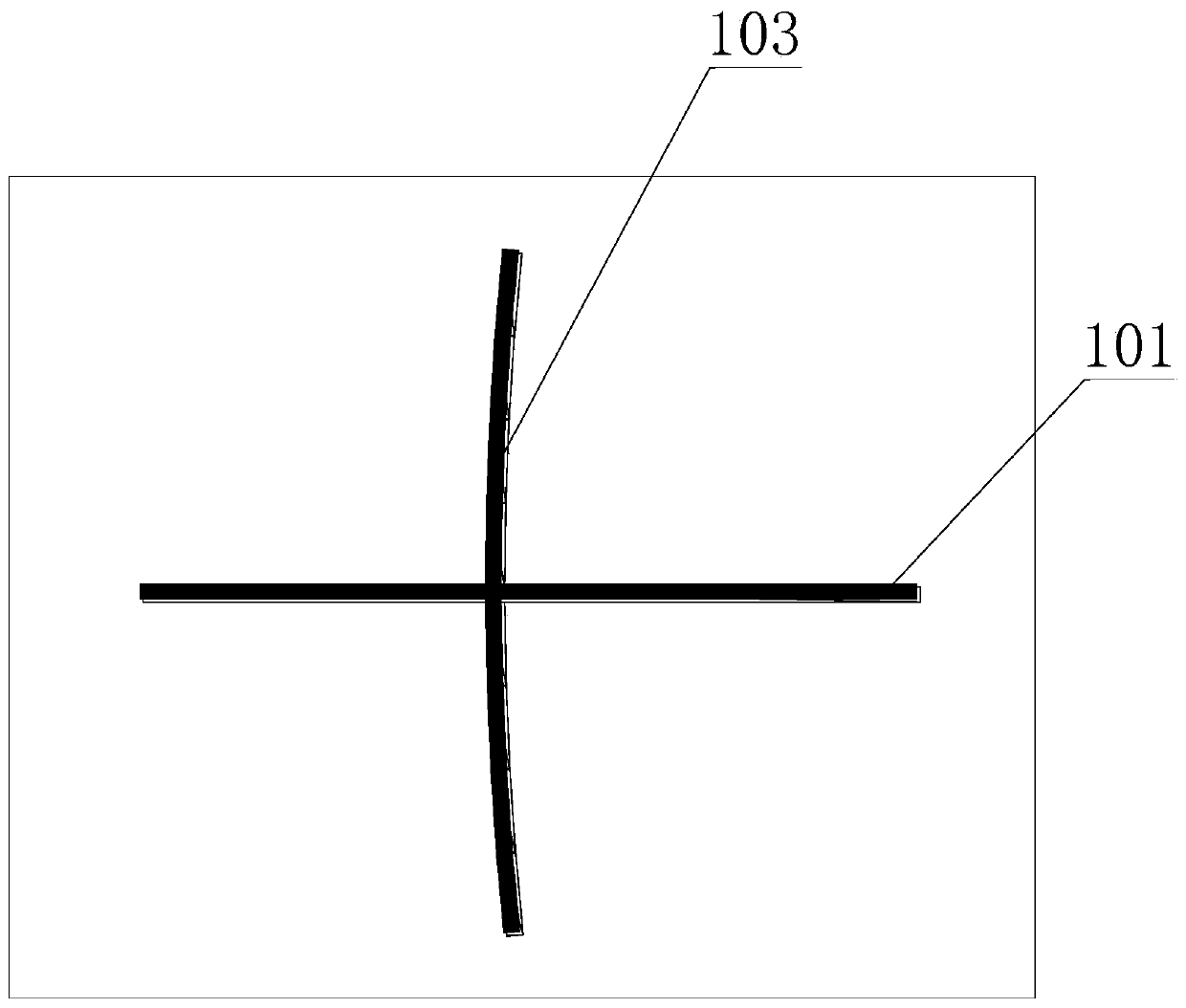

[0030] like figure 1 As shown, this embodiment provides a laser measurement device for slit detection and positioning, including a mechanical housing 201, a laser triangulation optical path disposed inside the mechanical housing 201, a circuit processing unit 207, an auxiliary illumination light source 208, and two windows glass 209;

[0031] The laser triangulation optical path, the circuit processing unit 207 and the auxiliary illumination light source 208 are all arranged inside the mechanical housing 201. In other embodiments, the auxiliary illumination light source can also be arranged outside the mechanical housing. In this embodiment, two pieces of window glass 209 Set at the bottom of the mechanical housing 201 , two pieces of window glass 209 are respectively located at the laser exit and incident positions of the mechanical housing 201 , and the circuit processing unit 207 is connected to the laser triangulation circuit and the auxiliary illumination light source 208...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com