Inertia assembly measuring mechanism for rail measurement

A technology of measurement mechanism and track, applied in the field of track measurement, can solve the problems of lack of real-time online continuous processing ability of disease information data, low efficiency, limited types of measured data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be described in detail below. Apparently, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other implementations obtained by persons of ordinary skill in the art without making creative efforts fall within the protection scope of the present invention.

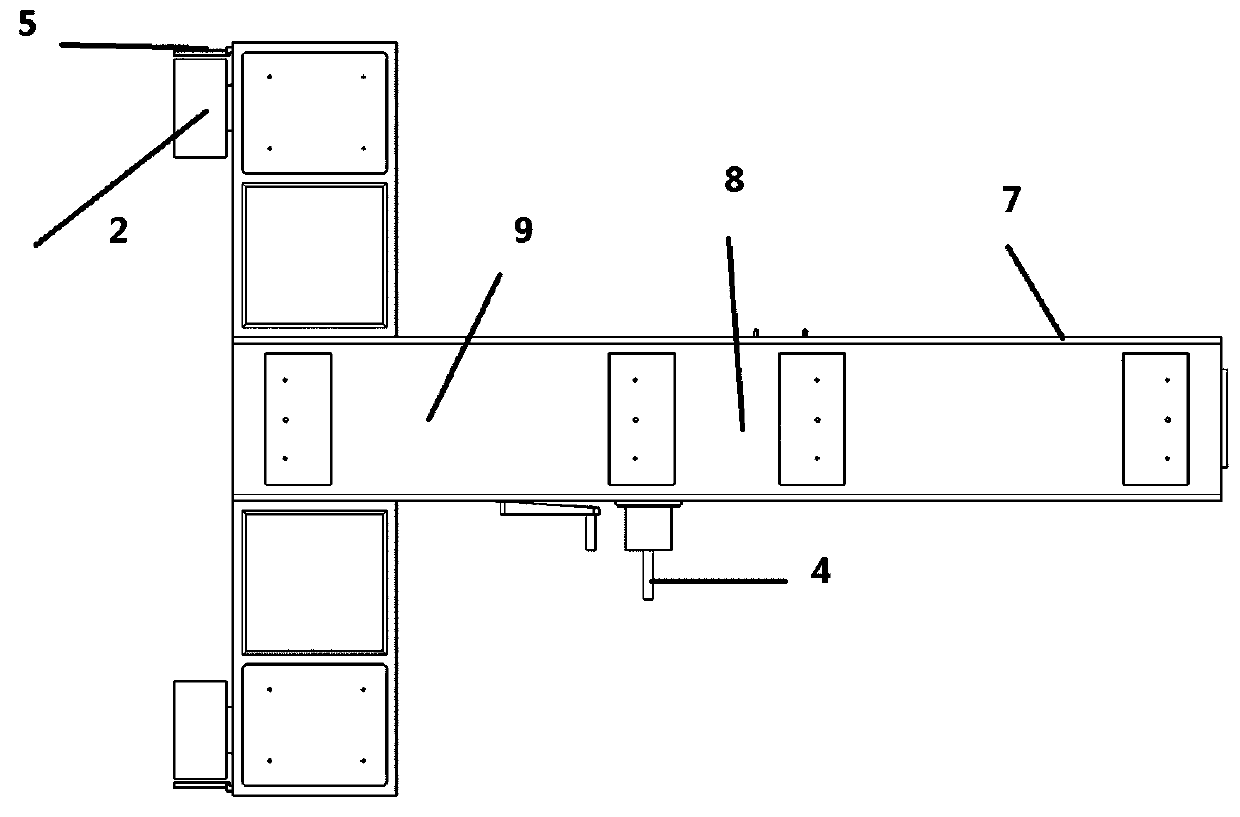

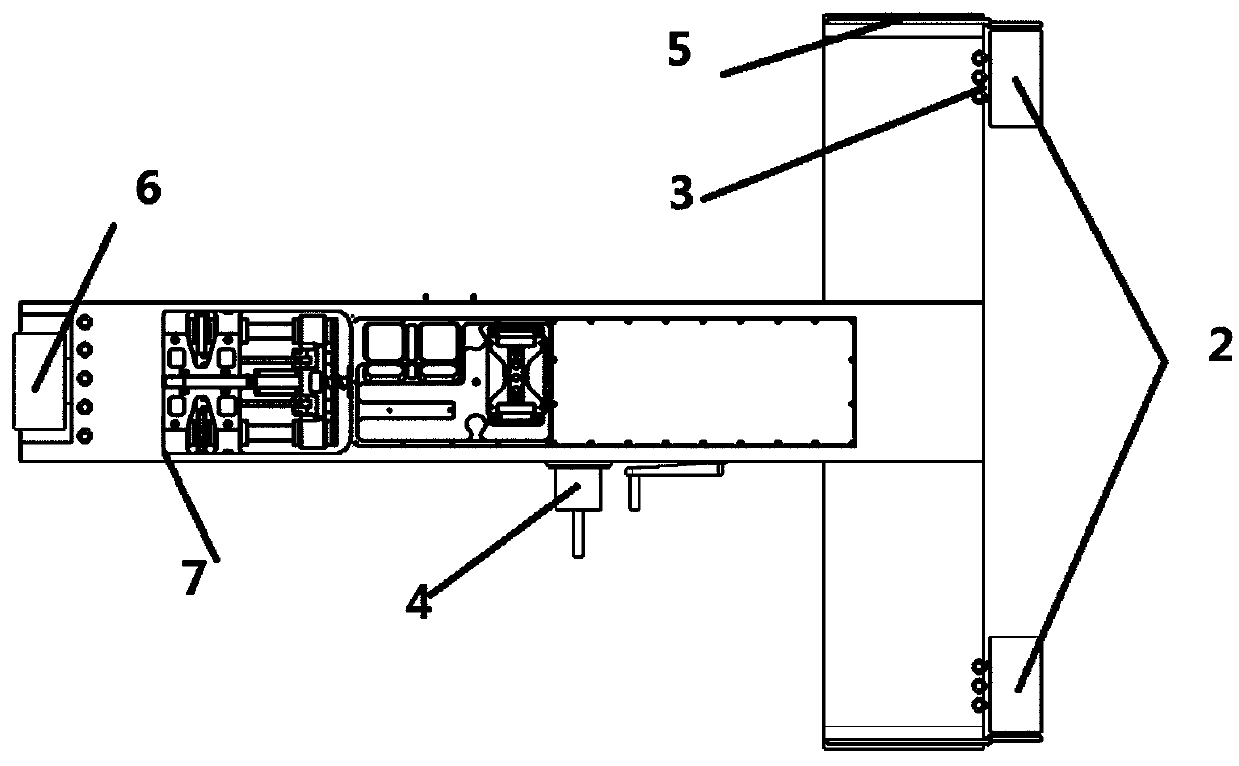

[0036] see Figure 1-Figure 9 As shown, an inertial component measurement mechanism for track measurement provided by the present invention includes a traveling device, an inertial measurement component 13, a battery, an inertial navigation connector 15, an expansion module interface 10, a spike interface 11, and a catenary geometric parameter processing device The installation part 8 and the track geometry parameter processing device installation part 9;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com