Thermal field crucible adjusting type heat preservation device for polycrystalline silicon

A polysilicon, regulating technology, applied in the direction of polycrystalline material growth, crystal growth, single crystal growth, etc., can solve the problems of inconvenient replacement, pick and place, unfavorable work efficiency, inconvenient disassembly, etc., and solve the inconvenient maintenance. and replacement, improve thermal insulation effect, avoid time-consuming and labor-intensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

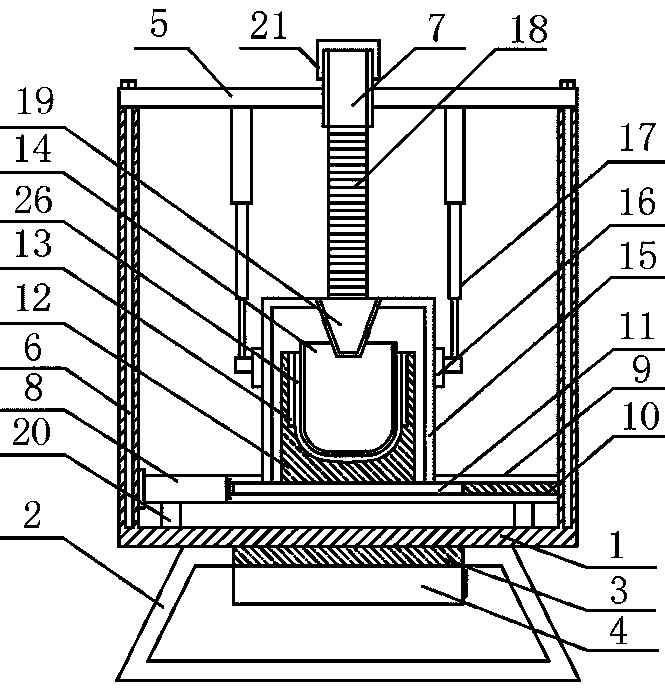

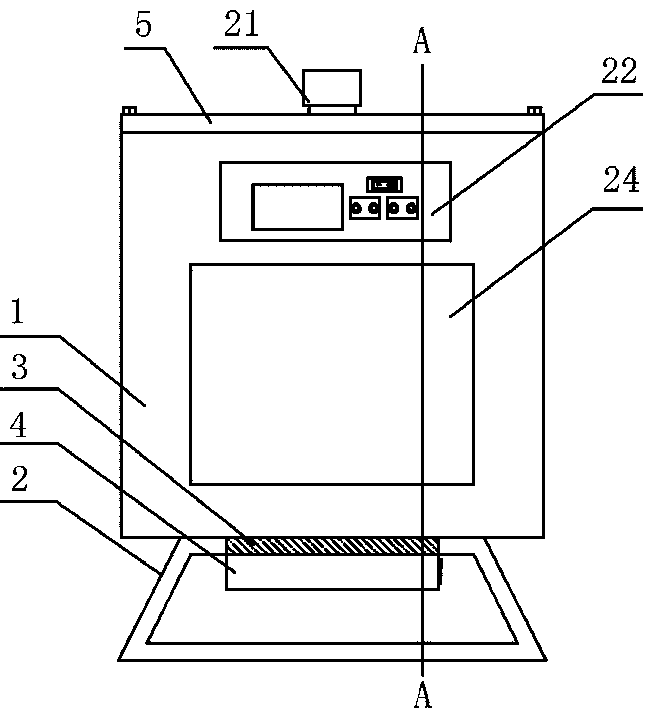

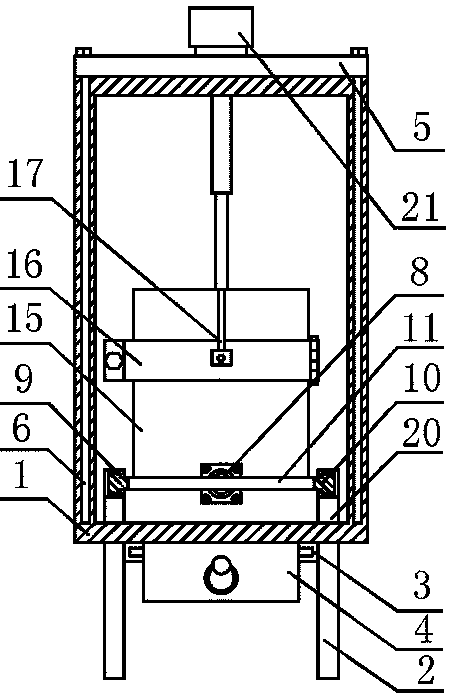

[0025] Example: see Figure 1-5 , a heat-field crucible-adjustable thermal insulation device for polysilicon, comprising a box body 1, the box body 1 is rectangular, and trapezoidal support seats 2 are fixedly connected to both sides of the bottom surface of the box body 1. A rectangular power supply box 4 is slidably provided on the bottom surface of the box body 1, an observation window 24 is provided in the middle of the front surface of the box body 1, a control panel 22 is provided at the upper end of the front surface of the box body 1, and a side surface of the box body 1 is provided with There is a rectangular first opening, a rectangular box door 25 is hinged on the side wall of the first opening, the top surface of the box body 1 is open, and a rectangular cover plate is fixedly connected to the open top surface 5. A circular feed pipe 7 is provided in the middle of the top surface of the cover plate 5, and second electric push rods 17 are fixedly connected to both s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com