Refractory brick vibration making machine with automatic feeding and sorting structure

A technology of automatic feeding and refractory bricks, which is applied in the direction of manufacturing tools, ceramic molding machines, supply devices, etc., can solve the problems of low overall equipment completion quality, difficult assembly and installation process, and high labor intensity, so as to achieve automation Increased production, increased safety, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

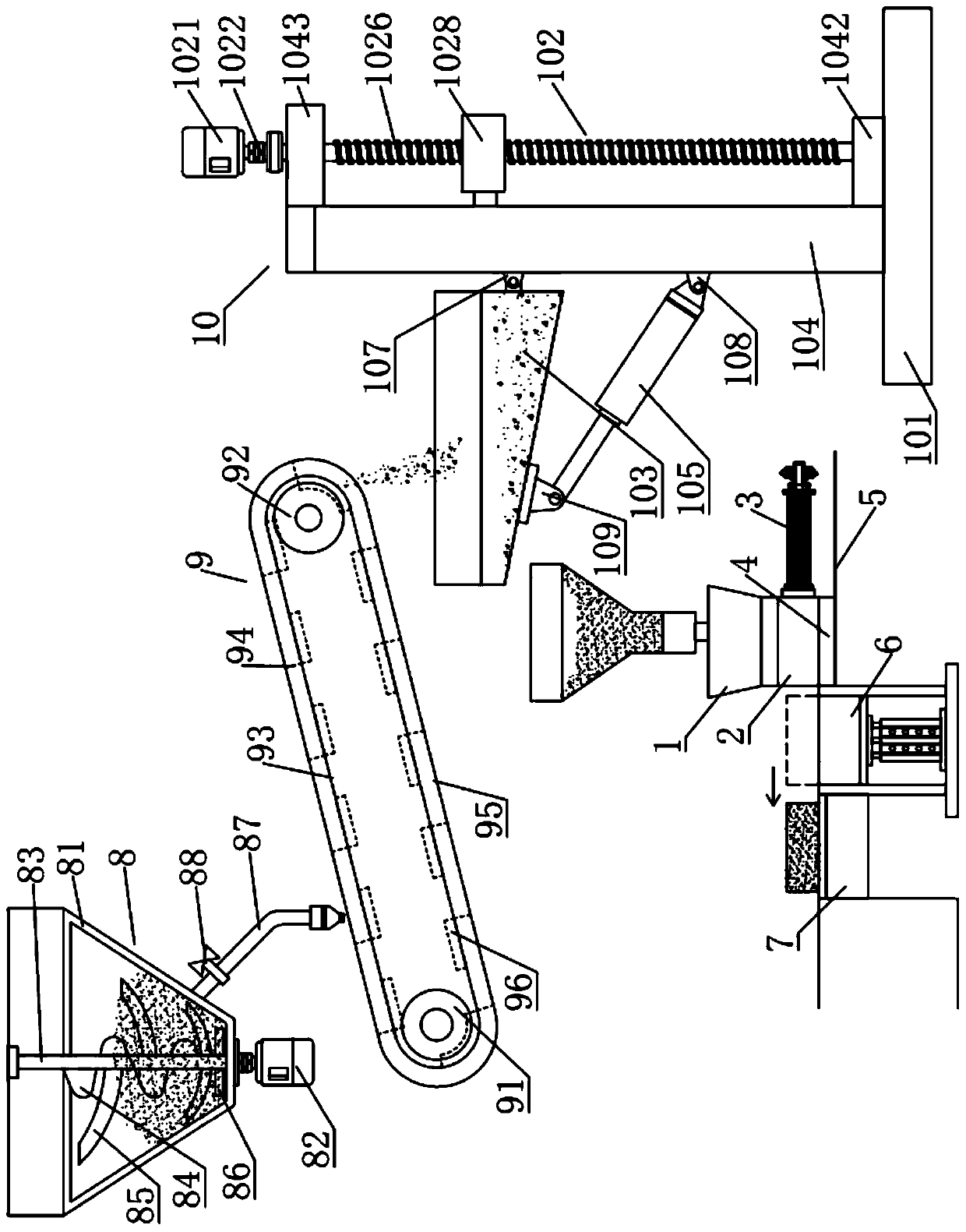

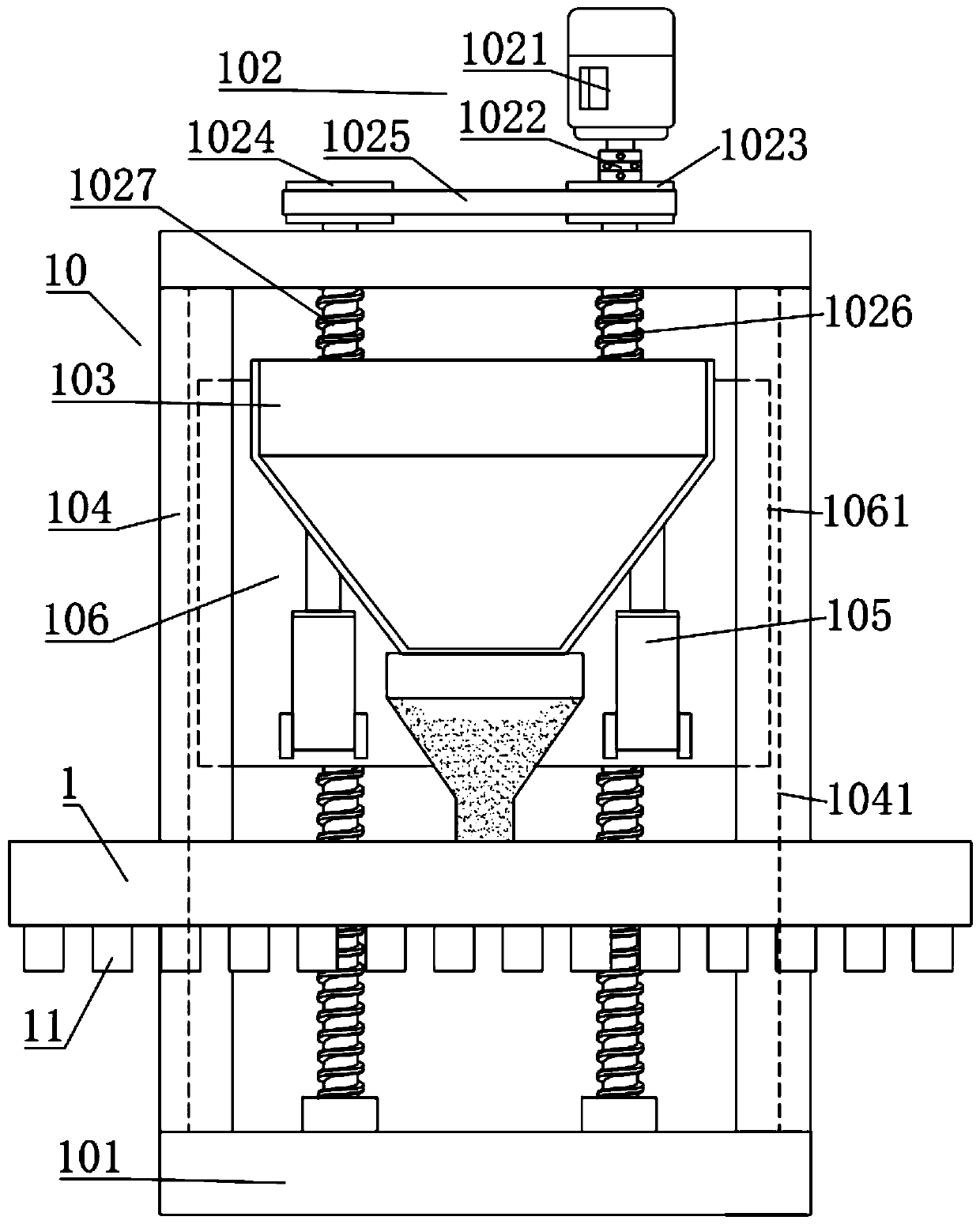

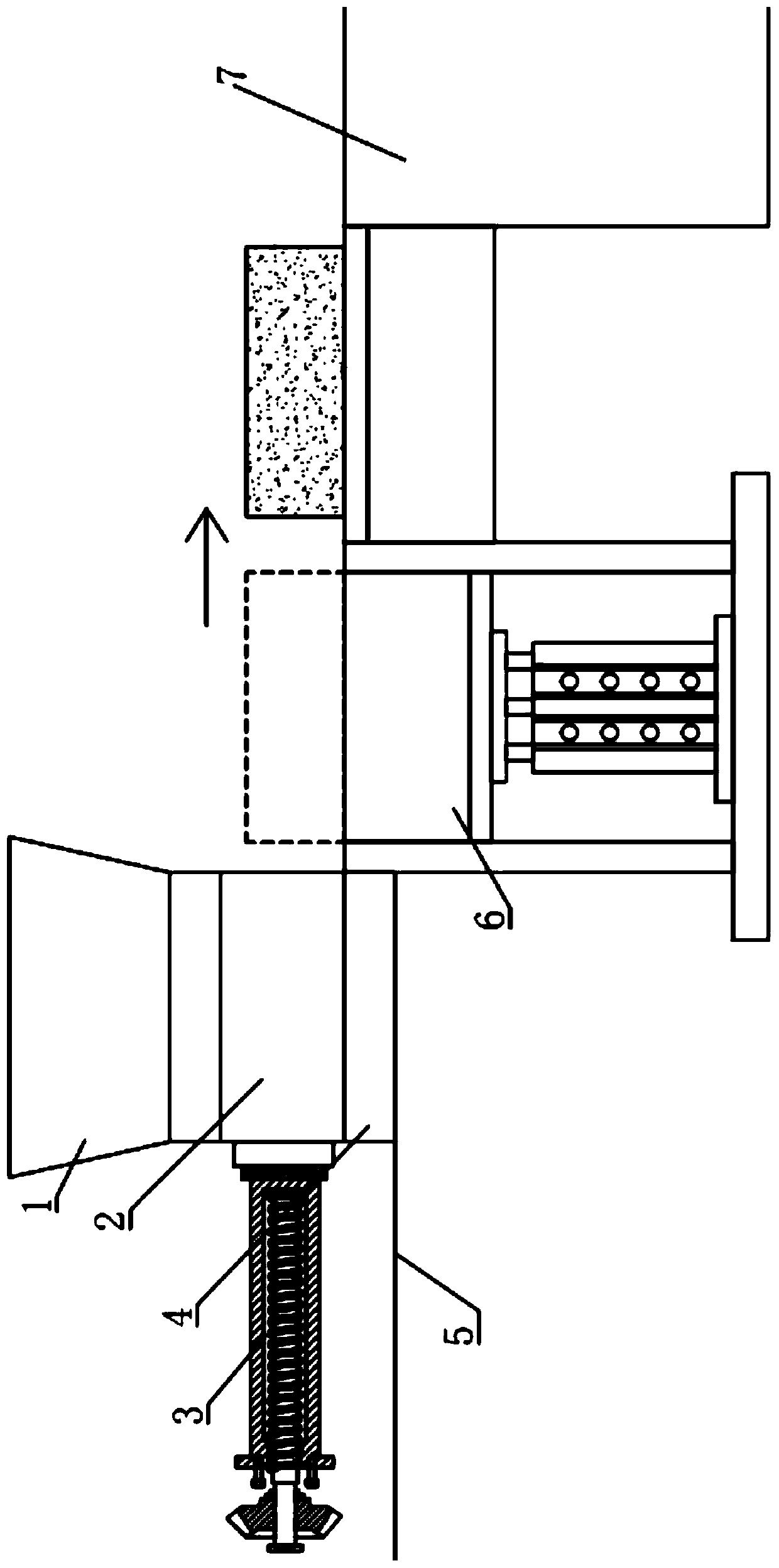

[0032] Such as figure 1 The shown refractory brick vibrating brick making machine with automatic feeding and sorting structure includes feeding box 1, raw material storage box 2, raw material storage box propulsion assembly 3, lower bottom plate 4, machine platform 5, and brick pressing Assembly 6 and brick transfer assembly 7, the lower bottom plate 4 and the raw material storage box propelling assembly 3 are all fixedly arranged on the machine platform 5, the brick pressing assembly 6 is located on one side of the machine platform 5, and the brick The transfer assembly 7 is arranged on the side of the brick pressing assembly 6 away from the machine platform 5, the raw material storage box 2 is arranged on the lower floor 4, and the feeding box 1 is located directly above the raw material storage box 2; wherein, the The brick-making raw material stirring assembly 8 includes a stirring cylinder 81, a stepping motor 82, a stirring shaft 83, a spiral stirring paddle 84, a group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com