Cutting device for wood-plastic composite profile processing

A technology of wood-plastic composite materials and cutting devices, which is applied in metal processing and other directions, can solve the problems of inconvenient disassembly and assembly of blades, reduce the application range of devices, and reduce the cutting efficiency of profiles, so as to increase the application range, ensure normal cutting, and ensure cutting efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

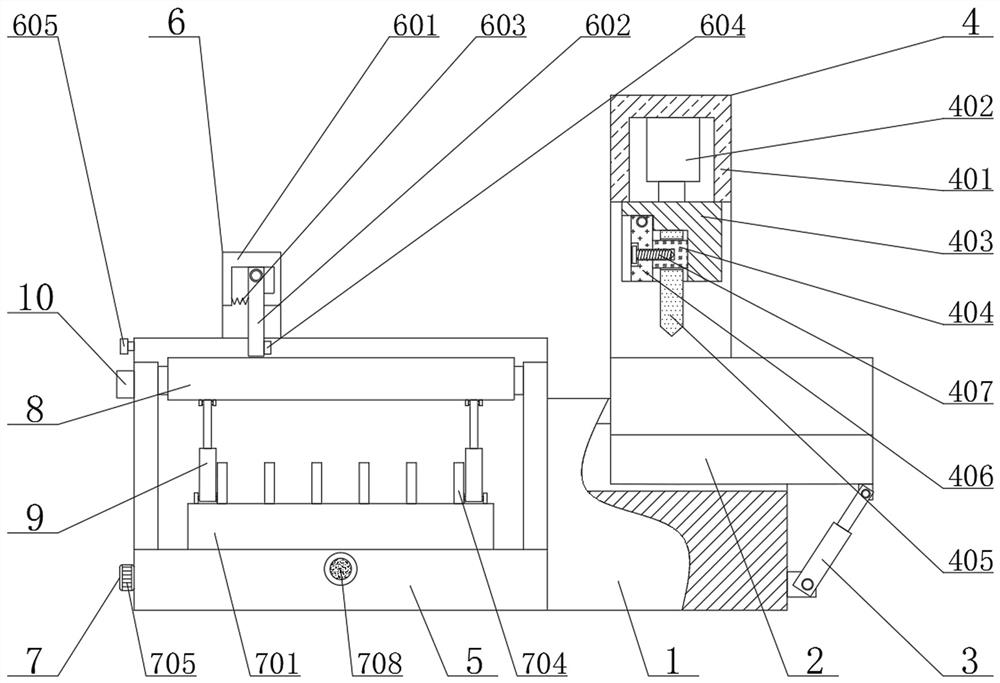

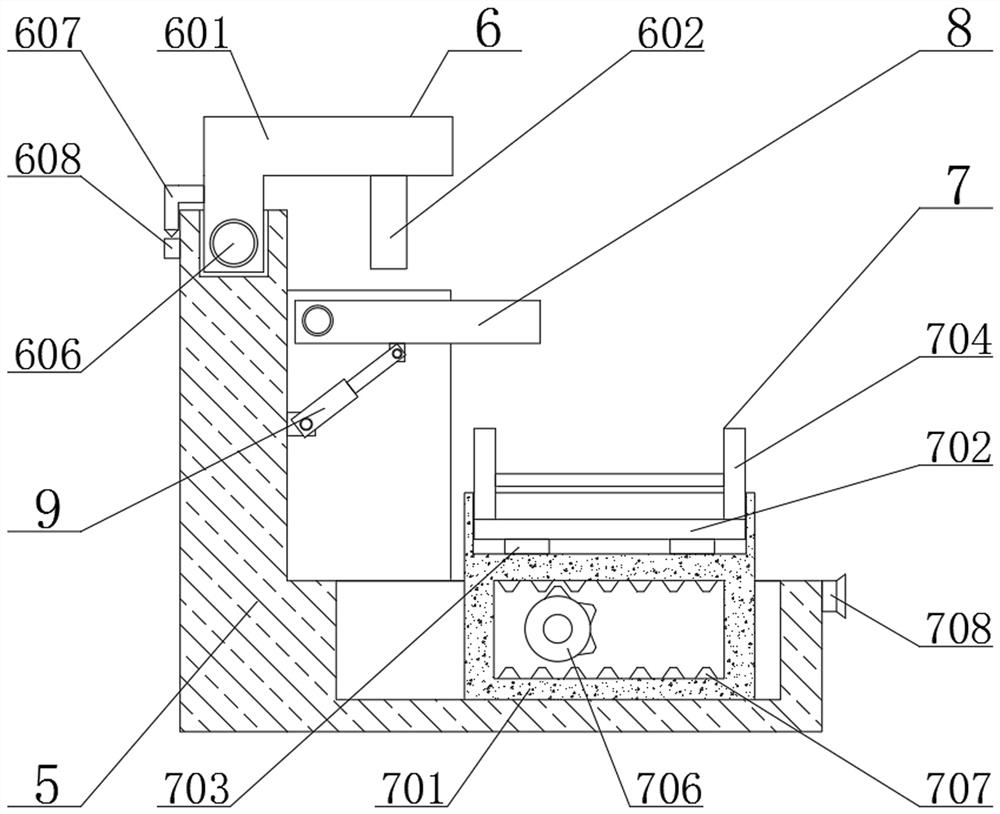

[0027] see figure 1 , image 3 , Image 6 and Figure 7 , the present invention provides a kind of technical scheme:

[0028]A cutting device for processing wood-plastic composite material profiles, comprising a fixed seat 1, a cutting device 4, a trigger device 6 and a receiving device 7, the top of the fixed seat 1 is slidably connected with a slider 2, and the right side of the bottom end face of the slider 2 passes through a rotating shaft A first electric telescopic rod 3 is rotatably connected, and the other end of the first electric telescopic rod 3 is rotatably connected with the fixed seat 1 through a rotating shaft, and a cutting device 4 is fixedly connected to the left side of the top surface of the slider 2. The cutting device 4 includes a positioning frame 401, The third electric telescopic rod 402, the support block 403, the positioning shaft 404, the cutting knife 405, the baffle plate 406 and the screw 407, a positioning frame 401 is fixedly connected to th...

Embodiment 2

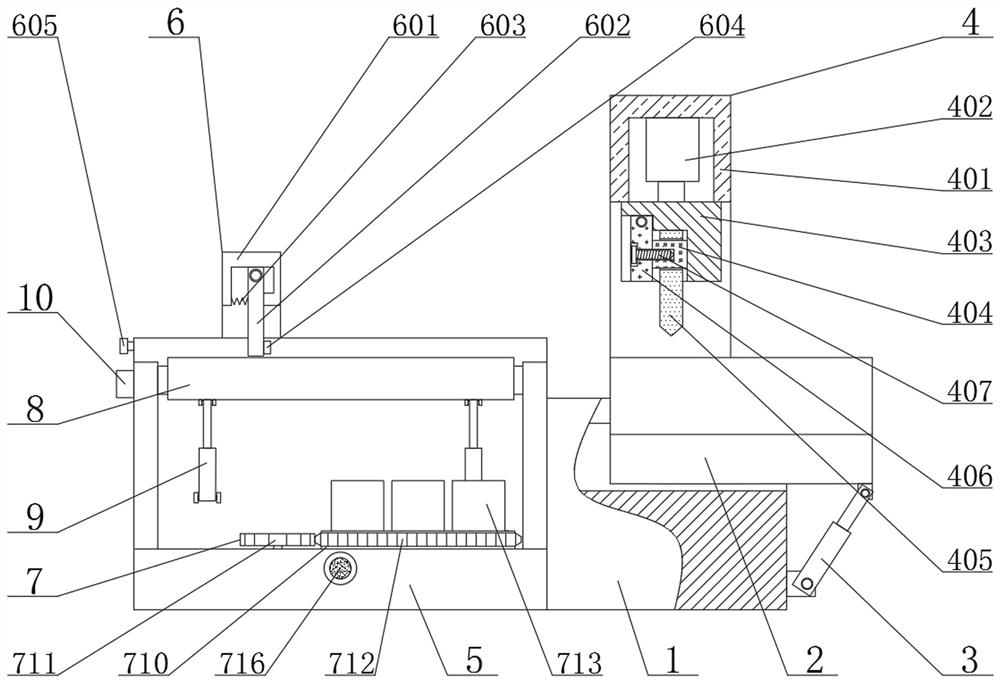

[0032] see figure 2 , Figure 4 , Figure 5 and Image 6 , the present invention provides a kind of technical scheme:

[0033] A cutting device for processing wood-plastic composite material profiles, comprising a fixed seat 1, a cutting device 4, a trigger device 6 and a receiving device 7, the top of the fixed seat 1 is slidably connected with a slider 2, and the right side of the bottom end face of the slider 2 passes through a rotating shaft A first electric telescopic rod 3 is rotatably connected, and the other end of the first electric telescopic rod 3 is rotatably connected with the fixed seat 1 through a rotating shaft, and a cutting device 4 is fixedly connected to the left side of the top surface of the slider 2. The cutting device 4 includes a positioning frame 401, The third electric telescopic rod 402, the support block 403, the positioning shaft 404, the cutting knife 405, the baffle plate 406 and the screw 407, a positioning frame 401 is fixedly connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com