An aluminum alloy propeller cold forging device

An aluminum alloy and propeller technology, applied in the field of aluminum alloy cold forging, can solve problems such as inability to take out completely, equipment downtime, damage to ships or pipelines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

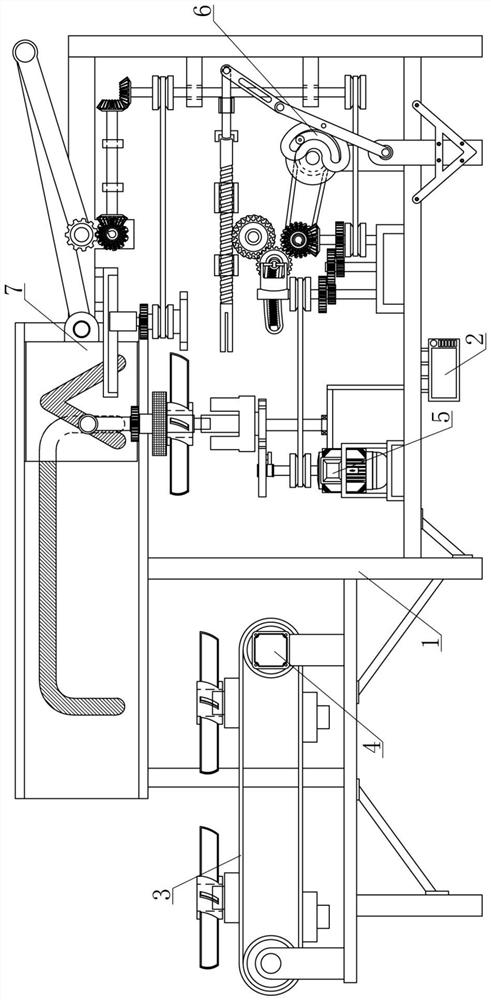

[0030] A cold forging device for an aluminum alloy propeller, such as Figure 1-10 As shown, it includes a mounting frame 1, a controller 2, a transmission belt mechanism 3, a micro motor 4, a step-stop mechanism 5, a blade bending mechanism 6 and an electromagnetic pick-and-place mechanism 7; the bottom right middle of the mounting frame 1 is connected with the controller 2 for welding; the left part of the inner bottom end of the installation frame 1 is welded with the transmission belt mechanism 3; the middle part of the inner bottom end of the installation frame 1 is provided with a step-stop mechanism 5; the right part of the inner bottom end of the installation frame 1 is provided with a blade bending mechanism 6. The middle part of the top of the installation frame 1 is provided with an electromagnetic pick-and-place mechanism 7;

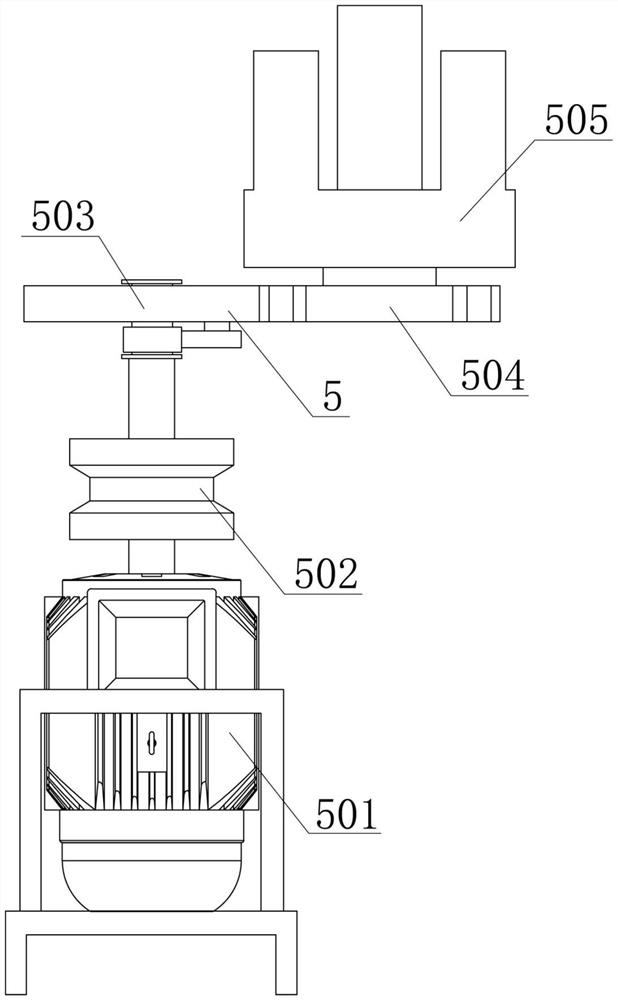

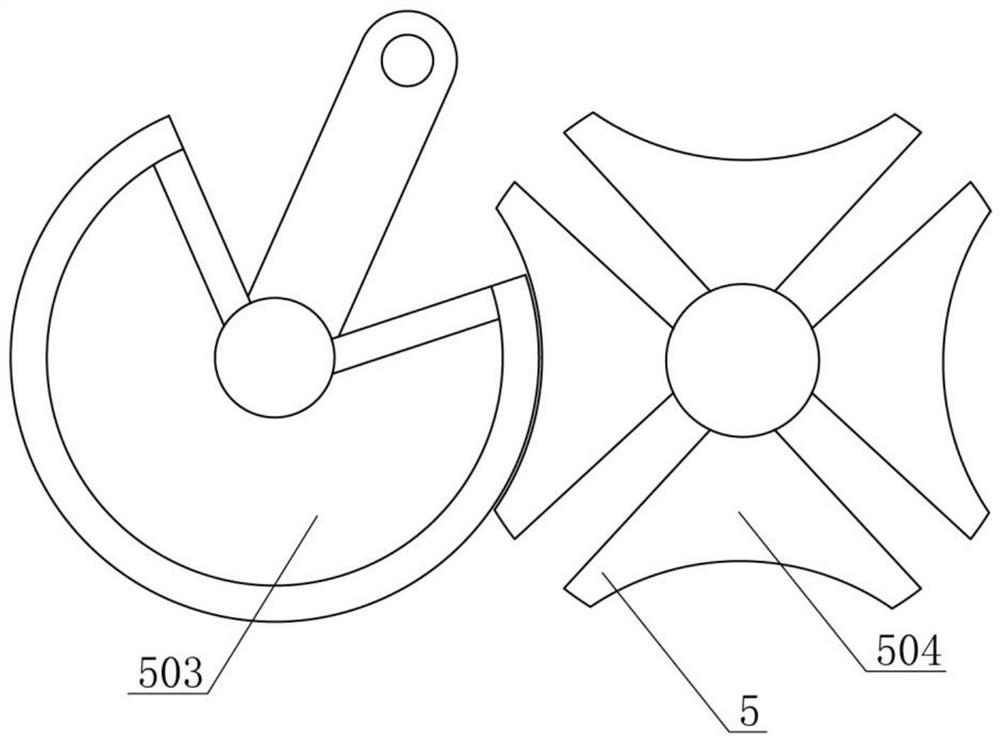

[0031] Wherein, the stop-stop mechanism 5 includes a stepper motor 501, a first transmission wheel 502, a driving pin wheel 503, a driven sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com