Heavy oil emulsion for catalytic cracking processing of heavy oil, preparation method and applications thereof

A kind of heavy oil catalysis and catalytic cracking technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

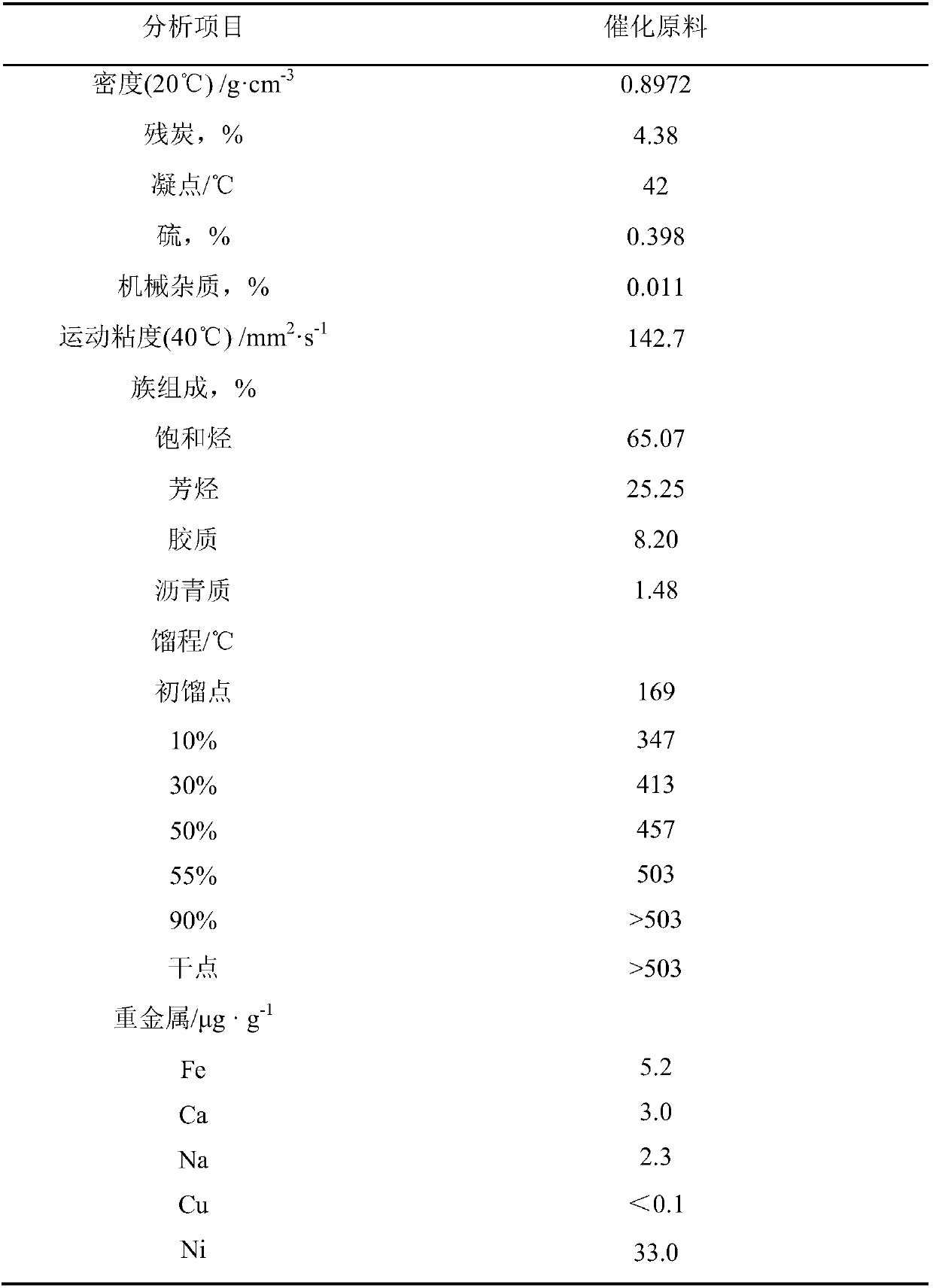

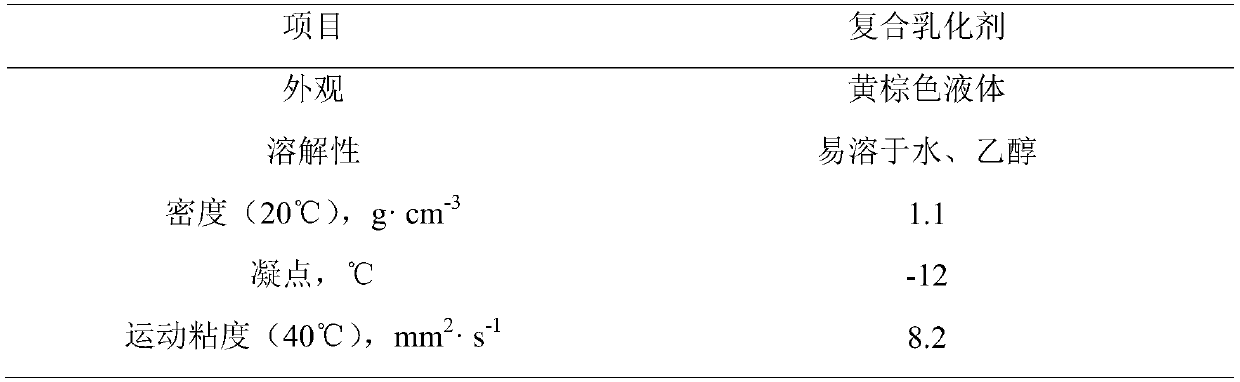

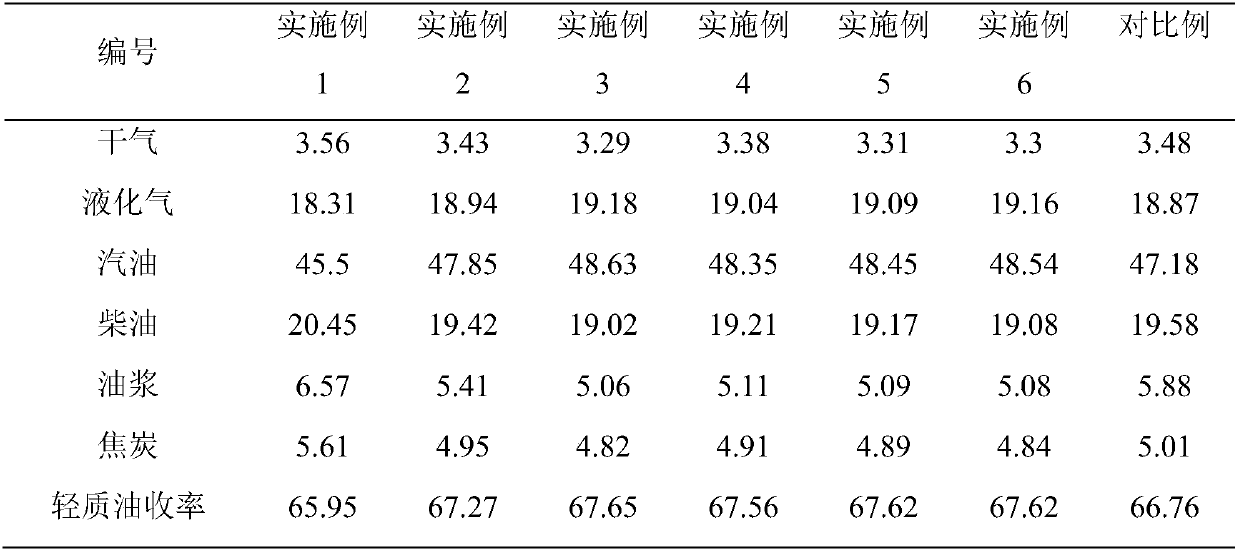

[0031] Calibration test is carried out on the 600,000 tons / year catalytic unit. At reaction temperature 515 DEG C, regeneration temperature 670 DEG C, industry's current balancing agent (RAG-11), wherein embodiment 1 test is a blank test, embodiment 2-6 is the test after raw material pretreatment (adopting the method of the present invention to process), Embodiment 2-4 Inorganic monodisperse porous membrane adopts aluminum oxide membrane, wherein the water in the dispersed phase of embodiment 2 accounts for 1% by weight of the heavy oil, and the amount of emulsifier accounts for 500ppm of the water; the water in the dispersed phase of embodiment 3 accounts for 1% of the heavy oil The weight ratio of the emulsifier is 2%, and the emulsifier accounts for 500ppm of water; the water in the dispersed phase accounts for 5% by weight of the heavy oil in embodiment 4, and the emulsifier accounts for 500ppm of the water; embodiment 5 adopts a metal film, and the water in the dispersed p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com