Integrated hydraulic station

A hydraulic station, integrated technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system safety, fluid pressure actuation system components, etc., can solve the problems of large floor area, hydraulic oil return, troublesome maintenance, etc. , to achieve the effect of small overall size, avoid hydraulic oil return, save space and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

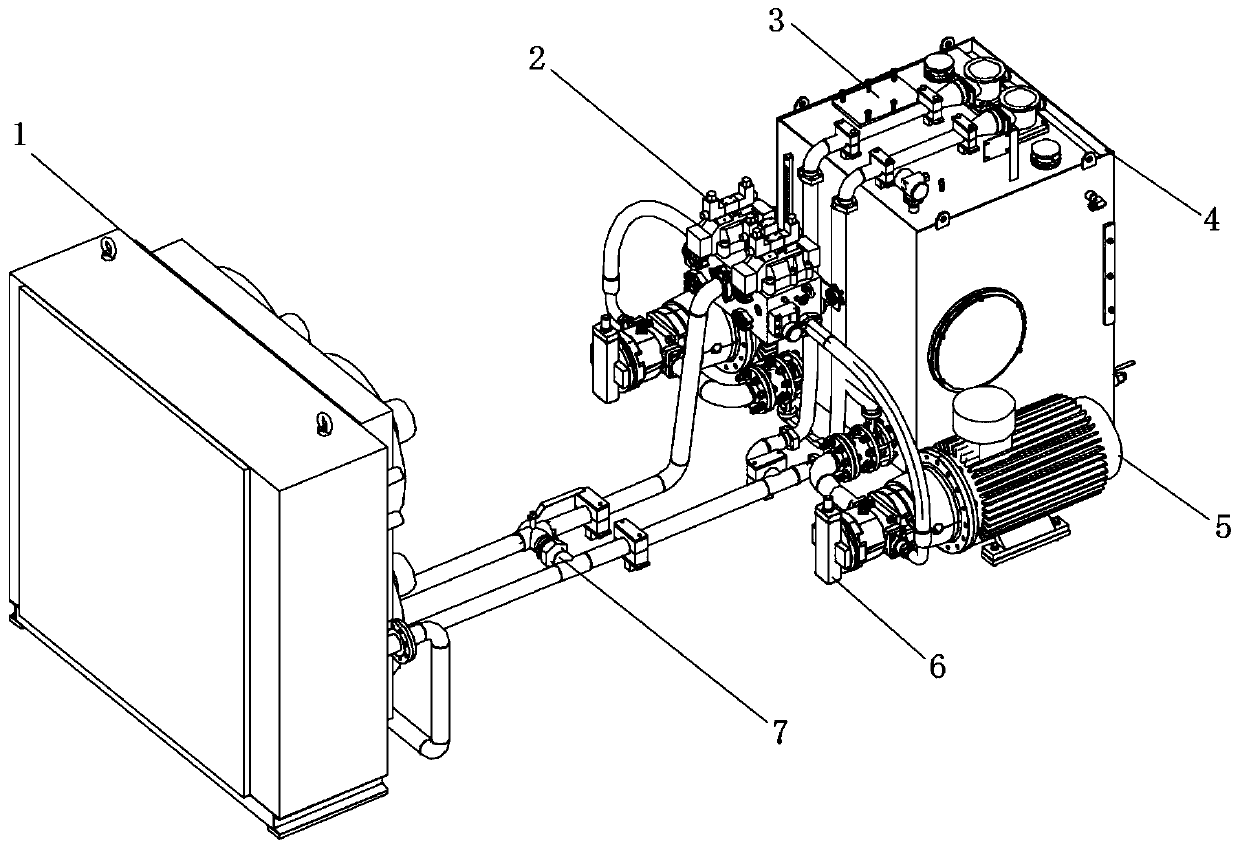

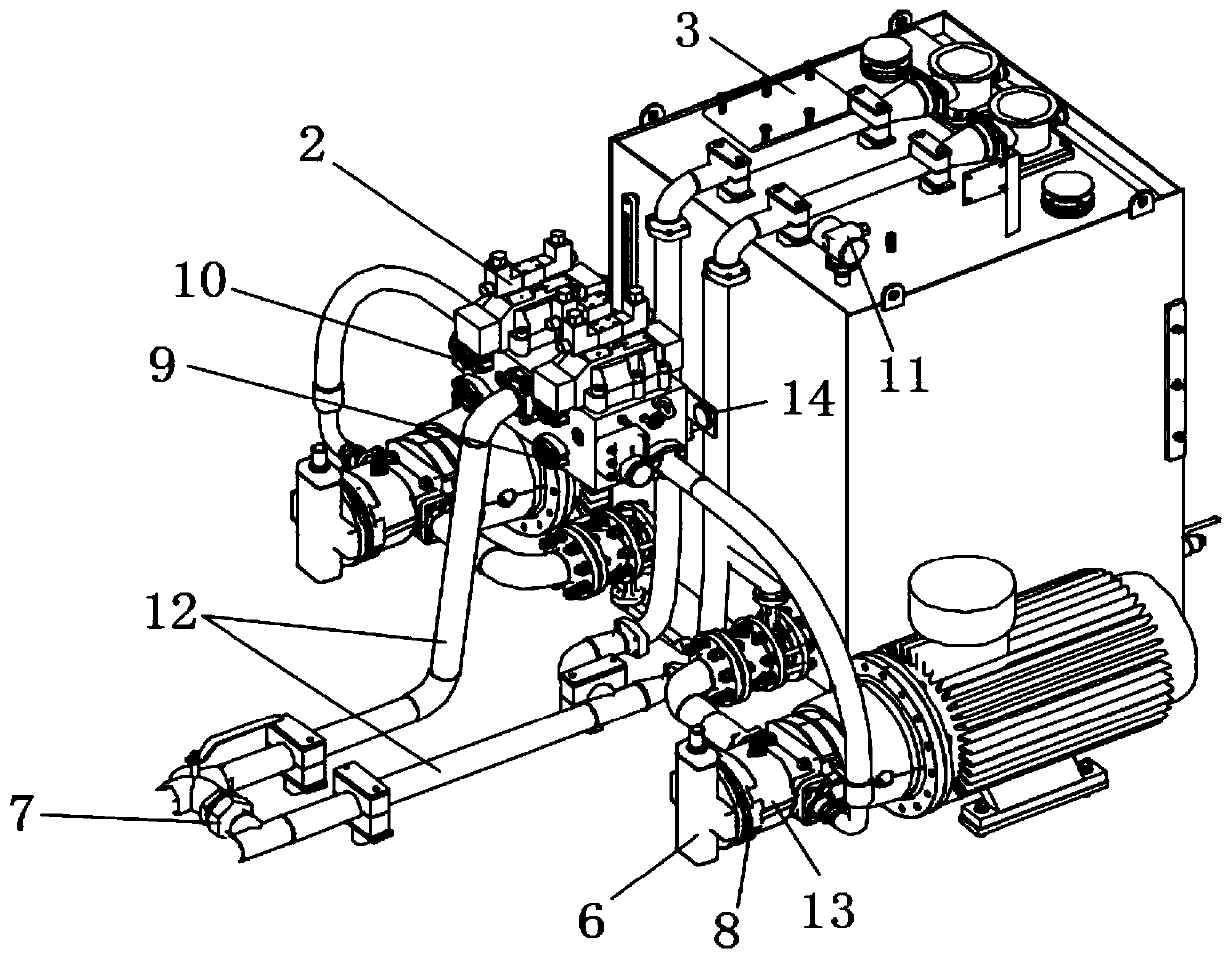

[0023] Such as Figure 1-3 As shown, an integral hydraulic station includes a cooler 1, a hydraulic oil tank 4, a motor system and a valve block 2, the hydraulic oil tank 4, a motor system and a valve block 2 are integrated into one set, and there are two sets of motor systems, and the motor system includes a motor 5. The plunger pump 6 and the elastic coupling 8, the valve block 2 is located at the upper part of the hydraulic oil tank 4, the motor system is located at the lower part of the hydraulic oil tank 4, and the motor 5 transmits power to the plunger pump 6 through the elastic coupling 8;

[0024] The valve block 2 is provided with an oil outlet 9, an oil return port 10, an unloading valve and an electro-hydraulic directional valve (not shown in the figure), and the unloading valve and the electro-hydraulic directional valve respectively control the pressure and flow direction of the hydraulic oil , to realize the reversing of the piston head in the hydraulic cylinder,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com