A method for removing chloride ions in chlorinated sulfuric acid solution using a photocatalytic fluidized bed

A fluidized bed and photocatalytic technology, applied in the fields of environmental protection, chemical industry, and metallurgy, can solve the problems of low electric adsorption and absorption, and achieve the effects of reducing concentration polarization, high economic benefits, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

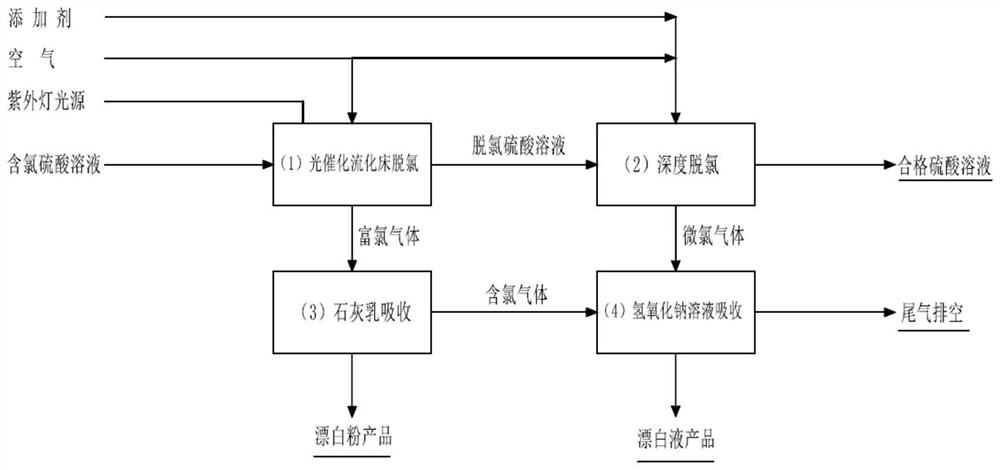

[0030] figure 1 It is a schematic flow chart of a method for removing chloride ions in a chlorine-containing sulfuric acid solution by using a photocatalytic fluidized bed according to the present invention.

[0031] to combine figure 1 , a method for removing chloride ions in a chlorinated sulfuric acid solution using a photocatalytic fluidized bed used in this embodiment, said method comprising photocatalytic fluidized bed dechlorination process 1, deep dechlorination process 2, milk of lime absorption Operation 3 and sodium hydroxide solution absorption operation 4 four operations, concretely carry out according to the following steps:

[0032] 1) The chlorine-containing sulfuric acid solution is sent to the photocatalytic fluidized bed dechlorination process, and under the action of ultraviolet light irradiation, high-efficiency photocatalysis is realized to obtain chlorine-rich gas and dechlorinated sulfuric acid solution;

[0033] 2) The chlorine-rich gas is sent to th...

Embodiment 2

[0037] This embodiment uses a method for removing chloride ions in a chlorinated sulfuric acid solution using a photocatalytic fluidized bed as described in Example 1. The concentration of chloride ions in the chlorinated sulfuric acid solution is 0.3 g / L, and the concentration of sulfuric acid is 0.5 g / L. M. The catalyst in the photocatalytic fluidized bed dechlorination step 1 is titanium dioxide, the catalyst carrier is activated carbon, and the diameter of the catalytic particles is 20 μm. In the photocatalytic fluidized bed dechlorination step 1, the operating linear velocity is 0.001 m / s, the bed expansion ratio is 1.1, and the temperature is 20°C. In the deep dechlorination step 2, the additive is hypochlorous acid, and the amount added is 1.0 times the amount of residual chlorine, and the concentration of chloride ions in the obtained qualified sulfuric acid solution is within 30 mg / L. In the lime milk absorption step 3, the mass fraction of lime milk is 40%, and the ...

Embodiment 3

[0039]This embodiment uses a method for removing chloride ions in a chlorinated sulfuric acid solution using a photocatalytic fluidized bed as described in Example 1. The chloride ion concentration in the chlorinated sulfuric acid solution is 2.0 g / L, and the concentration of sulfuric acid is 2.5 g / L. M. The catalyst in the photocatalytic fluidized bed dechlorination step 1 is zirconium dioxide, the catalyst carrier is silicon dioxide, and the diameter of the catalytic particles is 3.0 cm. In the photocatalytic fluidized bed dechlorination step 1, the operating linear velocity is 10 m / s, the bed expansion ratio is 3.8, and the temperature is 50°C. In the deep dechlorination step 2, the additive is hypochlorite, and the additive amount is 1.1 times the amount of residual chlorine, and the concentration of chloride ions in the obtained qualified sulfuric acid solution is within 30 mg / L. In the milk of lime absorption process 3, the mass fraction of milk of lime is 60%, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com