Ball forming device and preparation method of spherical carrier

A spherical carrier and ball-forming technology, which is applied in the direction of liquid separation into bead droplets and granulation, can solve the problems of reducing sphericity, tailing, ball wear, etc., to improve sphericity and wear resistance, and eliminate tailing phenomenon. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

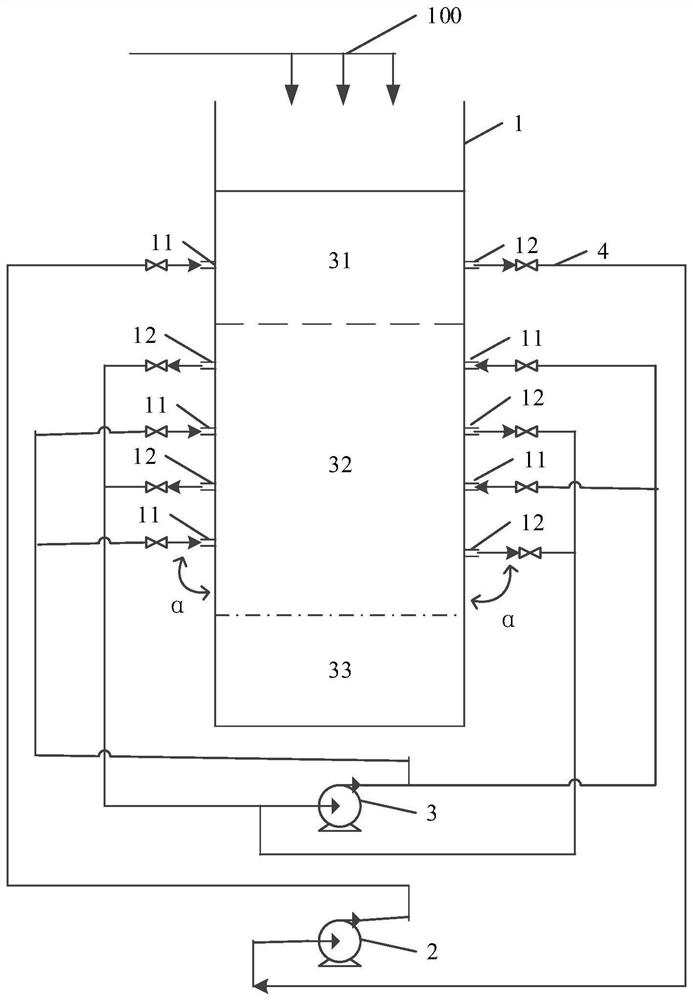

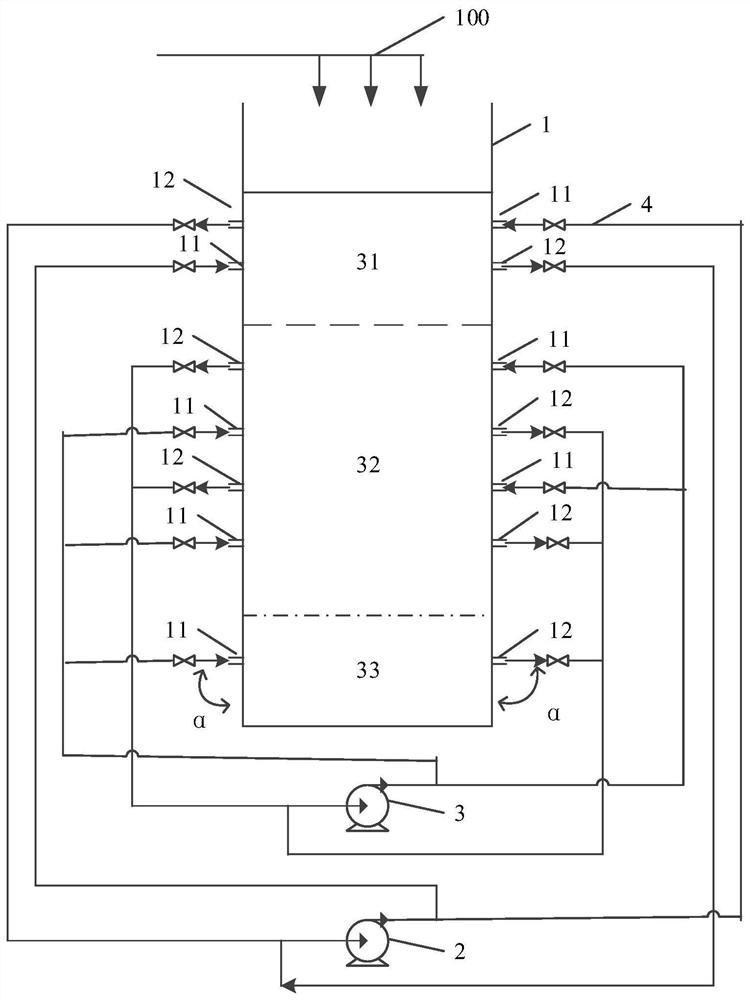

[0023] An embodiment, preferably, as figure 2 As shown, a row of liquid inlets 11 is arranged on the side wall of the collection area 33 of the container body 1 , and a row of liquid outlets 12 is oppositely arranged on the side wall of the other side. Two rows of liquid inlets 11 and liquid outlets 12 are arranged alternately on one side of the ball forming area, and two rows of liquid outlets 12 and liquid inlets 11 are alternately arranged on the other side of the sidewall. see specific Figure 4 , Figure 5 . The liquids in the solidification zone and the collection zone can be the same or two with similar properties.

[0024] In the present invention, the ball forming liquid circulation mechanism is used to circulate the ball forming liquid in the container body through the liquid inlet and the liquid outlet. Such as Figure 1-2 As shown, the first ball forming liquid circulation mechanism 2 may include a pipeline and a first circulation pump, the liquid inlet 11 of...

example 1

[0044] Cuboid-shaped oily ammonia column (container body) is used to form balls. The oily ammonia column is 2m long, 55cm wide, and 2m high. In addition to the oily ammonia column structure, the oil phase and ammonia water phase are used to form balls, solidification areas and collection areas. The heights are the same as in Comparative Example 1. Schematic diagram of the ball forming device figure 1 shown.

[0045] Set a row of liquid outlets at heights of 20cm, 90cm, and 190cm from the bottom of the oil ammonia column on the side wall of the oil ammonia column length direction, and set a row of liquid inlets at 55cm and 125cm heights; in the length direction of the oil ammonia column The side wall on the other side is respectively provided with a row of liquid inlets at heights of 20cm, 90cm, and 190cm from the bottom of the oil and ammonia column, and a row of liquid outlets is respectively arranged at heights of 55cm and 125cm. Each row of liquid inlets includes 10 liqui...

example 2

[0047] The method of example 1 adopts the container body of cuboid shape to carry out balling, and the structural representation of balling device is as follows figure 1 shown. Differently, the sphere-forming liquid was replaced with liquid paraffin in Comparative Example 2, the thickness of the oil phase was 195 cm, and the heights of the sphere-forming zone, solidification zone, and collection zone were all the same as the oil ammonia column. The sphericity of the pellets obtained after drop ball forming, water washing, drying and roasting is 0.970.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com