Welding equipment special for PE pipe sweat soldering and based on adjusting assembly

A technology of hot-melt welding and adjusting components, which is applied in the field of hot-melt welding of PE pipes, can solve the problems of reducing the efficiency of hot-melt welding of PE pipes, high labor intensity of workers, and low welding efficiency, so as to meet the needs of hot-melt welding and increase Scope of application, effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

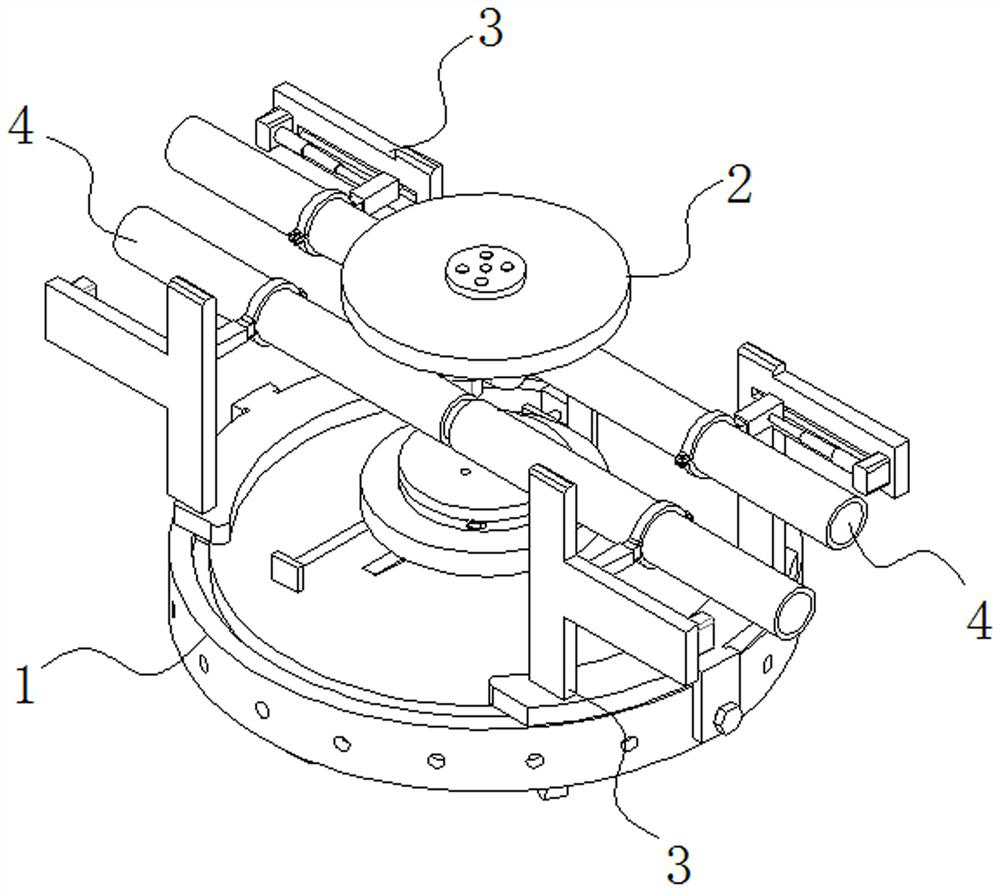

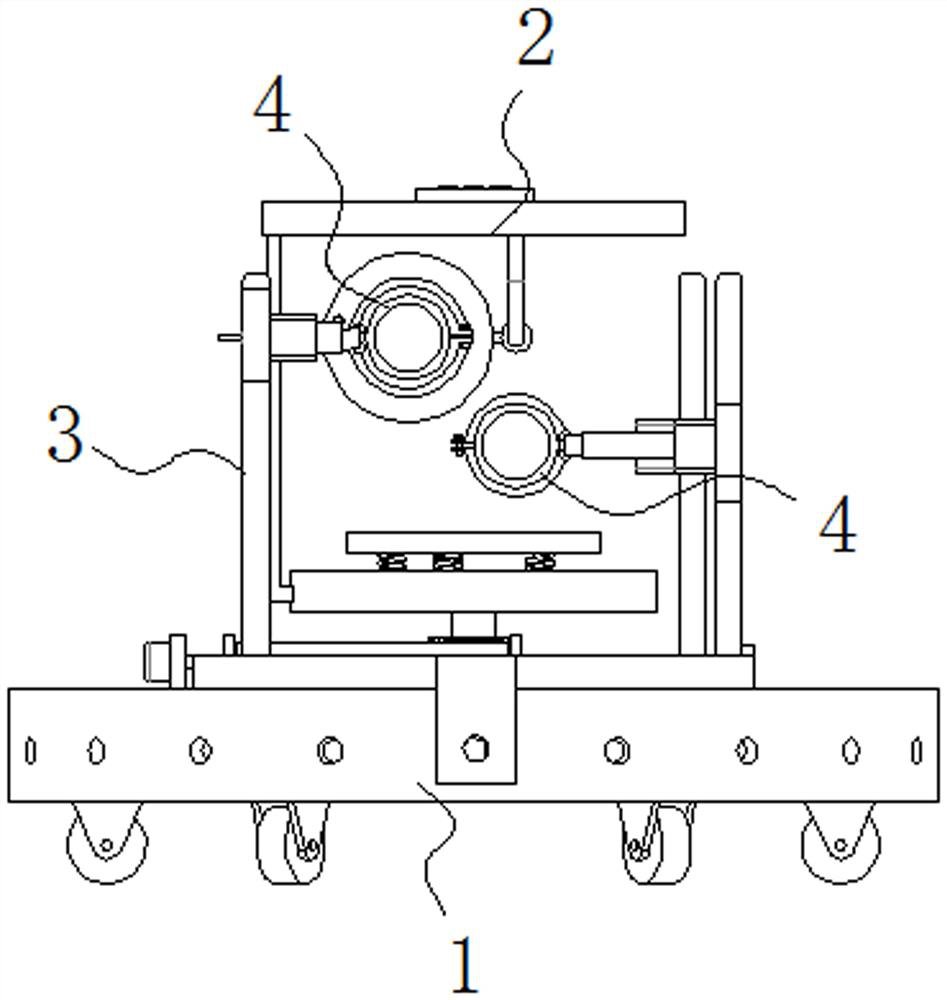

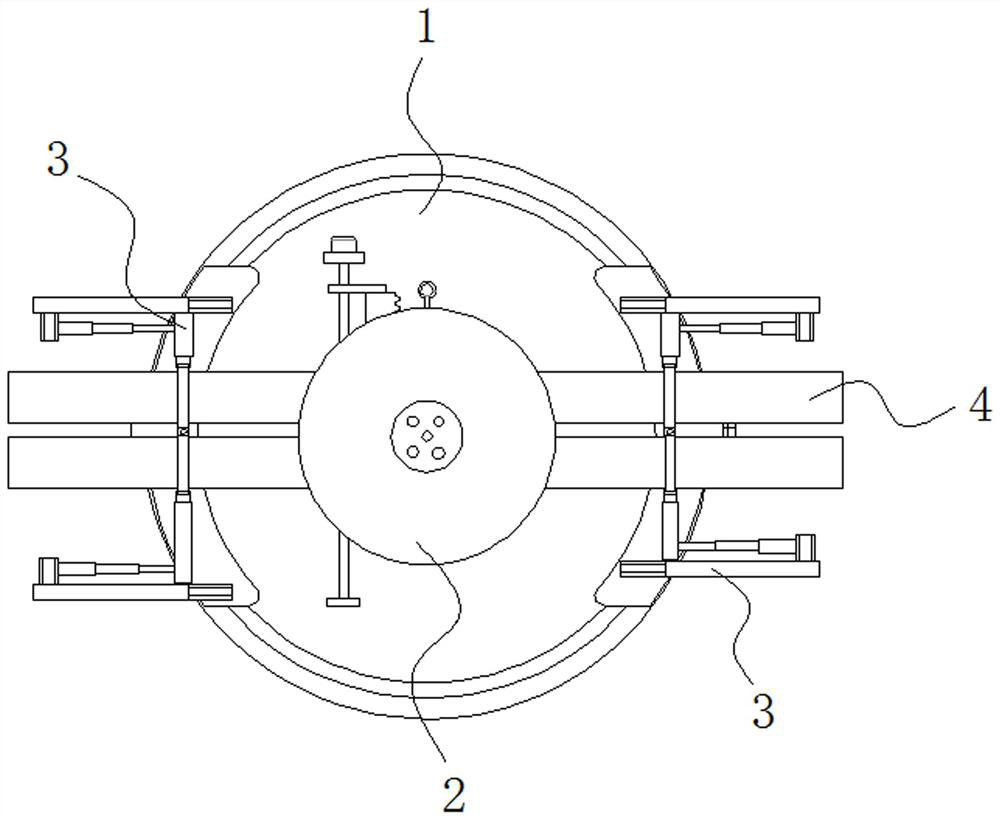

[0057] see Figure 1-14 , the present invention is a kind of welding equipment specially used for hot-melt welding of PE pipes based on adjustment components, including a mobile base 1;

[0058] The center position of the upper surface of the mobile base 1 is rotationally connected with a hot-melt mechanism 2; the upper surface of the mobile base 1 is symmetrically slidably connected with two supporting mechanisms 3;

[0059] Wherein, the support mechanism 3 is composed of a support assembly 31 and a clamp assembly 32; a fixed connection between the support assembly 31 and the clamp assembly 32; the PE pipe 4 is clamped inside the clamp assembly 32; In order to heat-melt the end faces of the PE pipes 4 to be welded, so as to realize the heat-melt welding of the two PE pipes 4 , the support mechanism 3 is used to support and fix the PE pipes 4 .

[0060] Wherein, the hot-melt mechanism 2 includes two fixed disks 201 arranged up and down; the two fixed disks 201 are fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com