Method of adsorbing and desorbing benzene in acetylene

An acetylene and desorption technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of difficult treatment and utilization, strong irritating odor and malodorous odor, and relieve the pressure of subsequent treatment and utilization. The effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Adsorb and desorb benzene in acetylene according to the following methods, specifically:

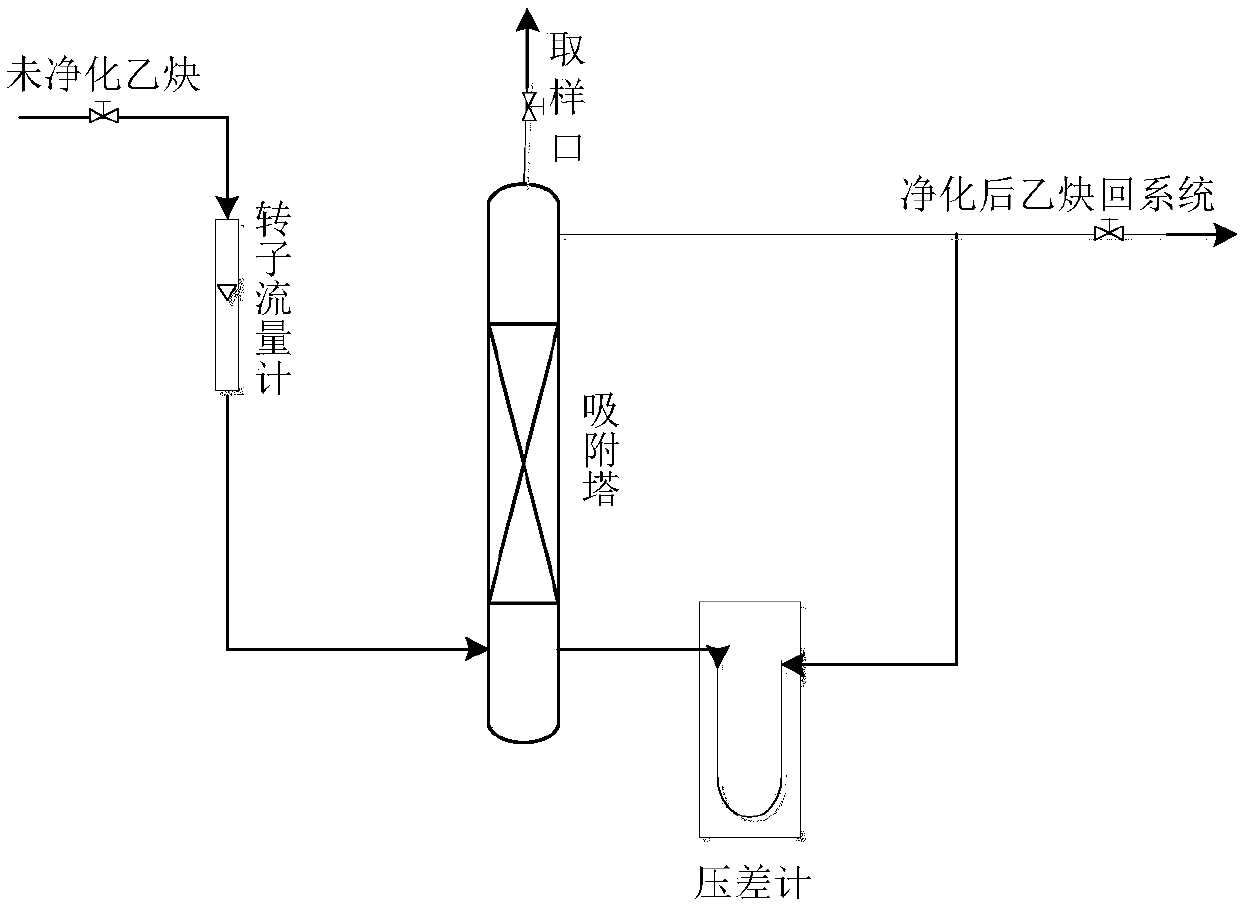

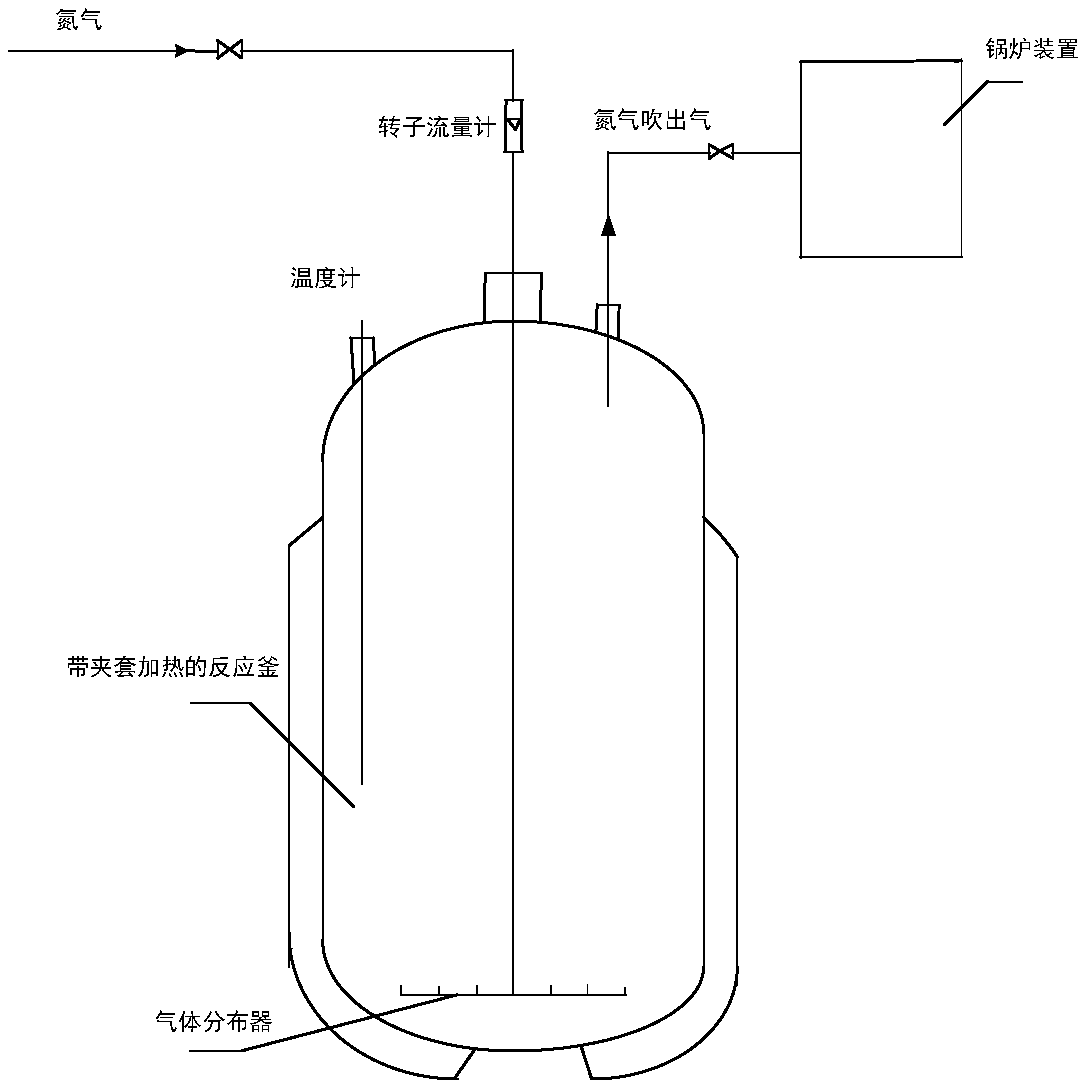

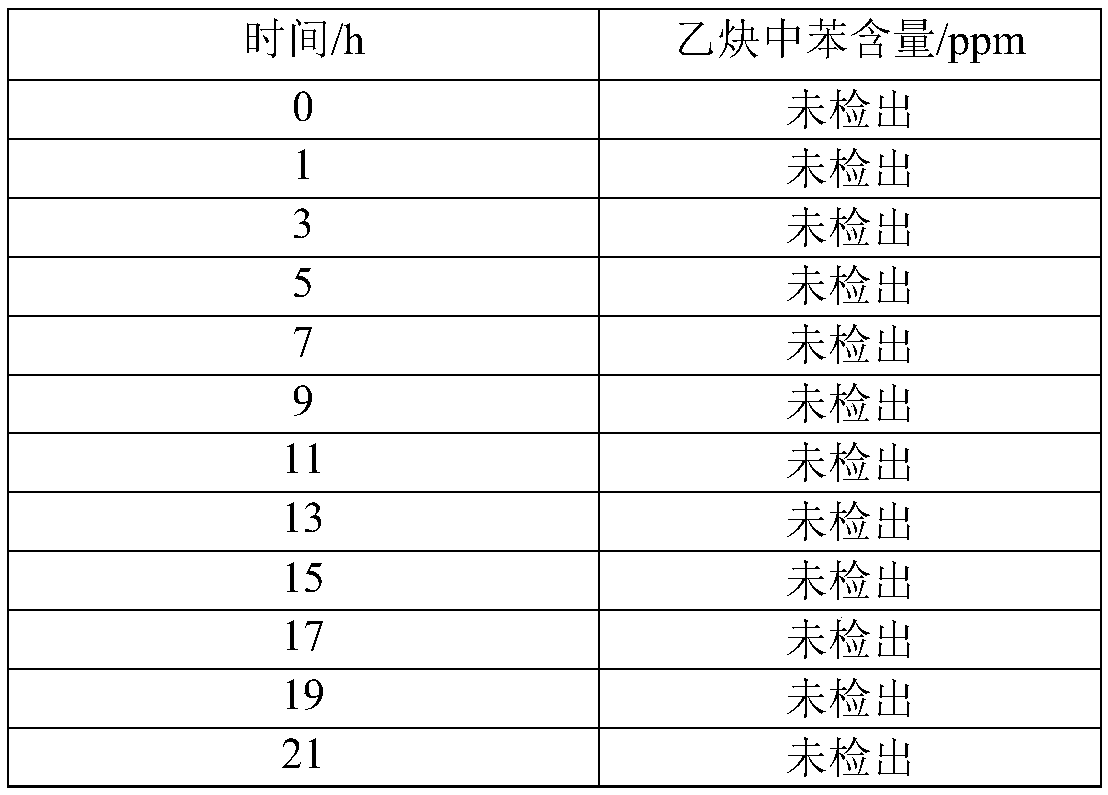

[0025] A. According to figure 1 The device shown in the figure processes acetylene. The unpurified acetylene in the acetylene workshop passes through the rotameter and then enters the adsorption tower equipped with activated carbon. The purified acetylene enters the synthesis section. The outlet is equipped with a sampling point, and the inlet and outlet of the adsorption tower are connected to the differential pressure gauge. , used to measure the pressure difference between inlet and outlet, the filling volume of activated carbon is 350ml, the flow rate of acetylene is 90L / h, and the space velocity of acetylene is 257h -1 , the pressure difference between the inlet and outlet of the adsorption tower during operation is 5mm water column, and the pressure difference between the inlet and outlet of the adsorption tower is 5mm, and it is respectively at 0h, 1h, 3h, 5h, 7h, 9h, 11h, ...

Embodiment 2

[0039] Adsorb and desorb benzene in acetylene according to the following methods, specifically:

[0040] Experimental device used, step and parameter are identical with embodiment 1, and difference is the intake of acetylene and nitrogen, and the intake of acetylene is 45L / h in steps A and C, and the air velocity of acetylene is 129h -1 , the nitrogen intake in step B is 40L / h, and the nitrogen space velocity is 114h -1 , step A in 0h, 4h, 8h, 12h, 16h, 20h, 24h, 26h, 28h, 30h, 32h, 34h, 36h, 38h, 40h, 42h, 44h, 46h, 48h, 50h, 52h, 54h and After 56h, measure the benzene content and the water content in the acetylene at the outlet of the adsorption tower, and the results are as shown in table 4; the assay method of the benzene content in the acetylene is the same as the detection method of the benzene content in the acetylene at the outlet of the adsorption tower in step A of embodiment 1; After 0h, 0.5h, 1h, 1.5h, 2h, 2.5h, 3h, 3.5h, 4h, 4.5h, 6.5h and 8.5h, measure the benzene...

Embodiment 3

[0053] Adsorb and desorb benzene in acetylene according to the following methods, specifically:

[0054] Experimental device used, step and parameter are identical with embodiment 1, and difference is the intake of acetylene and nitrogen, and the intake of acetylene is 175L / h in steps A and C, and the air velocity of acetylene is 500h -1 , the nitrogen intake rate in step C is 140L / h, and the nitrogen air velocity is 400h -1 , measure the benzene content and water in the acetylene at the outlet of the adsorption tower after 0h, 2h, 4h, 6h, 8h, 12h, 13h, 14h, 15h, 16h, 17h, 18h, 19h, 20h, 21h, 22h and 23h respectively in step A Content, the results are shown in table 7; Determination method is identical with the detection method of benzene content and water content in the outlet acetylene of embodiment 1 step A adsorption tower; In step B, respectively in 0min, 5min, 10min, 15min, 20min, 25min, 30min Measure the benzene content in the gas blown out of the reactor outlet after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com