Negative pole piece and secondary battery

A negative pole piece and negative electrode technology, applied in the field of electrochemistry, can solve the problems of deteriorating battery power performance and long-term reliability, achieve good cycle performance and kinetic performance, improve kinetic performance, and facilitate infiltration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

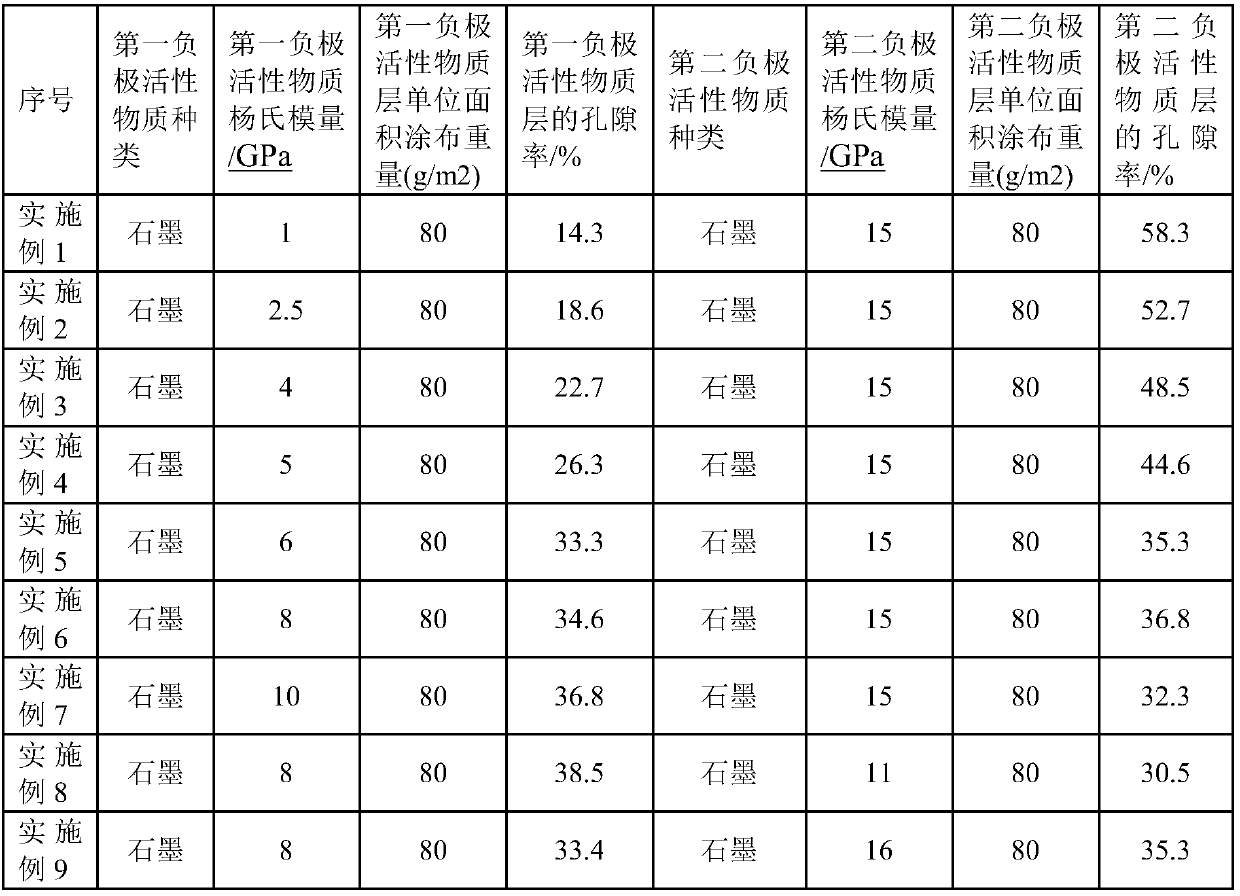

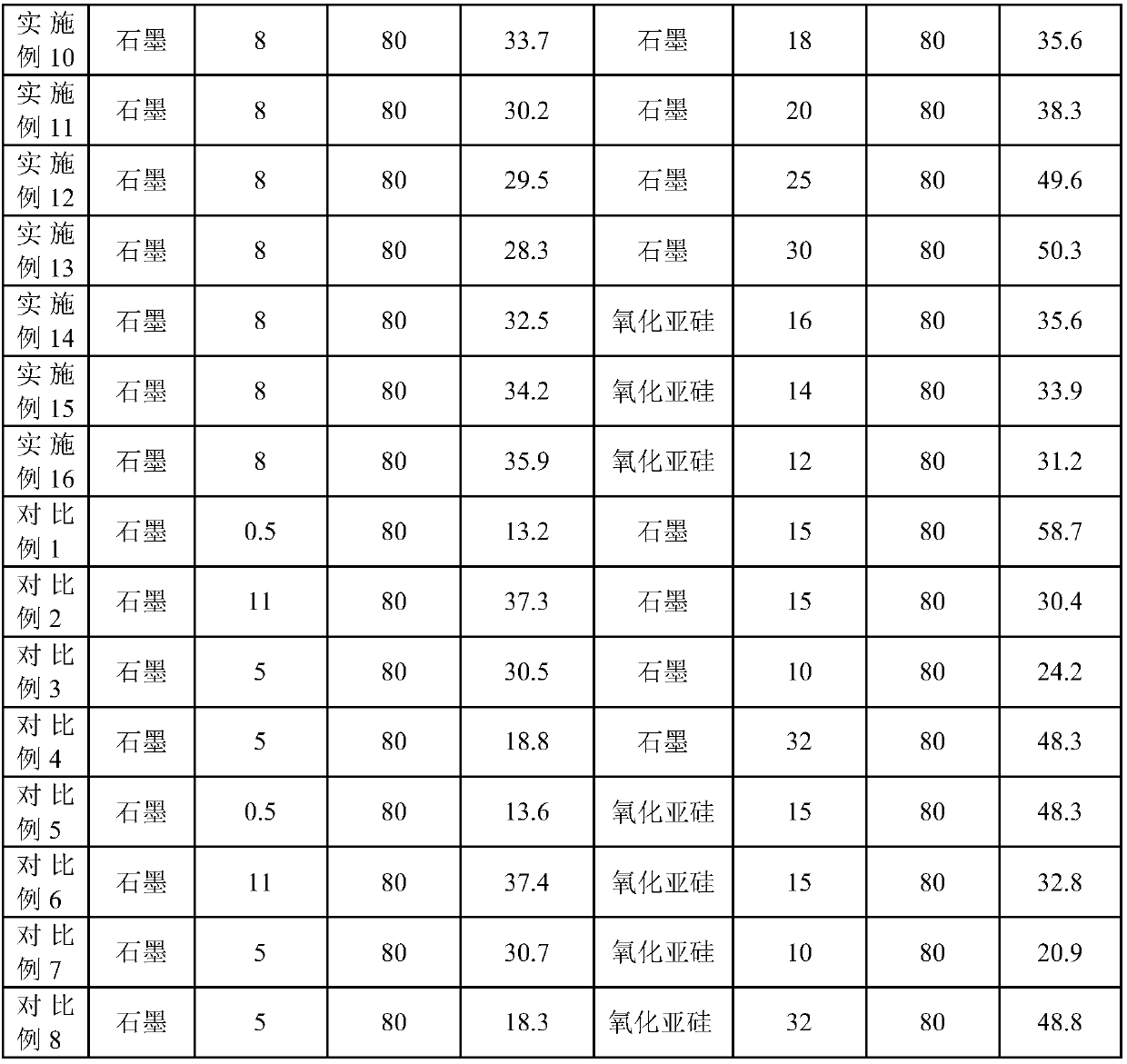

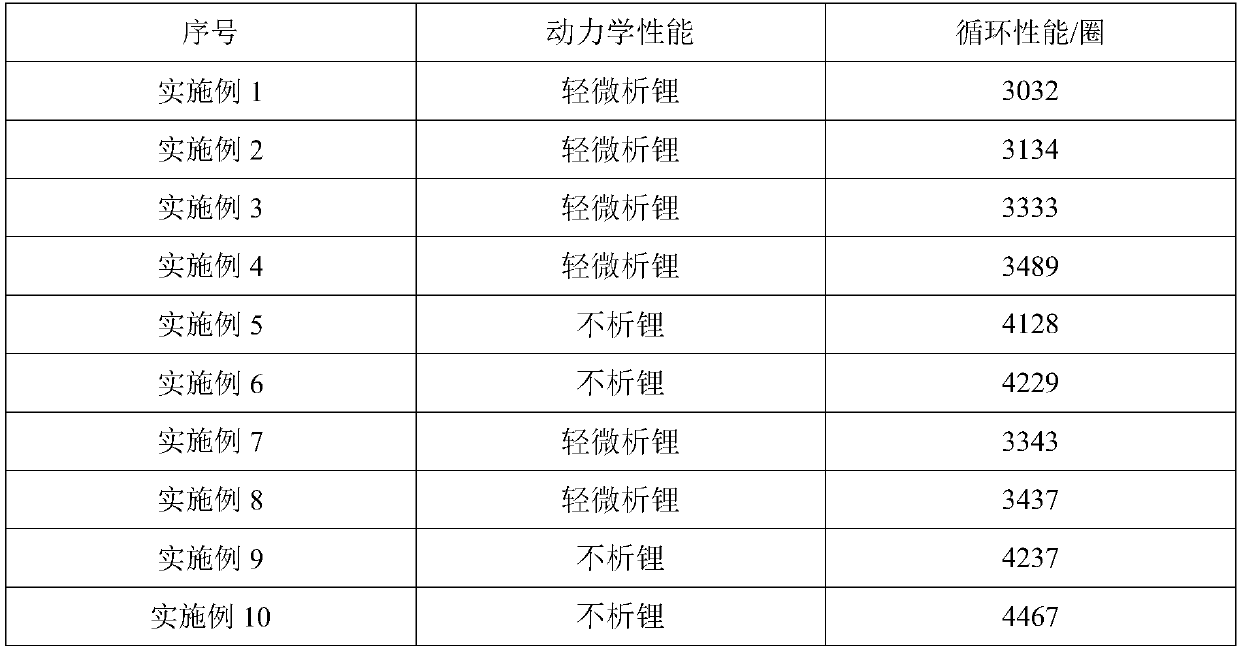

Examples

preparation example Construction

[0026] The negative electrode sheet provided by the first aspect of the present invention can be prepared by a known method in the art. For example, the preparation method of the negative electrode sheet may include: forming a first negative electrode active material layer on at least one surface of the negative electrode current collector and forming a second negative electrode active material layer on the first negative electrode active material layer. Those skilled in the art can usually choose an appropriate method to form the negative electrode active material layer according to the structure of the electrode sheet, for example, methods such as coating method, spray coating method, and vapor phase deposition method can be used.

[0027] The second aspect of the present invention provides a secondary battery, which includes the negative electrode sheet provided by the first aspect of the present invention.

[0028] The secondary battery provided by the present invention al...

Embodiment 1

[0038] Positive electrode sheet preparation: Mix positive active material lithium iron phosphate, conductive agent (Super P), and binder (PVDF) in a ratio of 96:2:2, add solvent (NMP), and stir under the action of a vacuum mixer until the system into a uniform and transparent shape to obtain the positive electrode slurry; the positive electrode slurry is evenly coated on the positive electrode current collector aluminum foil; the positive electrode current collector coated with the positive electrode slurry is dried at room temperature and then transferred to an oven for drying, and then subjected to cold pressing, Slitting and other processes to obtain the positive electrode sheet.

[0039] Negative pole piece preparation:

[0040] (1) Mix the first negative electrode active material graphite, conductive agent (Super P), CMC (carboxymethyl cellulose), binder (styrene-butadiene rubber) at a mass ratio of 94.5:1.5:1.5:2.5, and solvent (Deionized water) was uniformly mixed unde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com