Five-axis numerically-controlled machine tool control method based on digital twins

A technology of numerical control machine tools and control methods, applied in computer control, program control, general control systems, etc., to achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

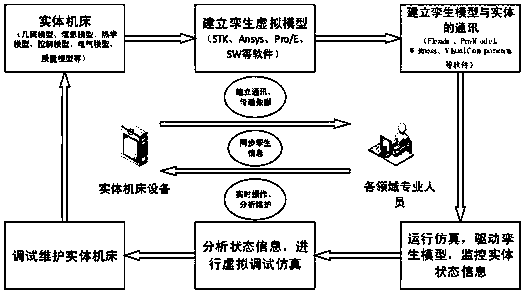

[0019] A digital twin-based five-axis CNC machine tool control method, characterized in that: the steps of the control method are:

[0020] 1) Establish twin virtual models similar to physical entities: establish twin virtual models similar to physical entities on 3D software such as SW, 3DMAX, PRO / E, and keep consistent in structure and model. The twin virtual models include mechanical models , control model, quality model, geometric model and information model;

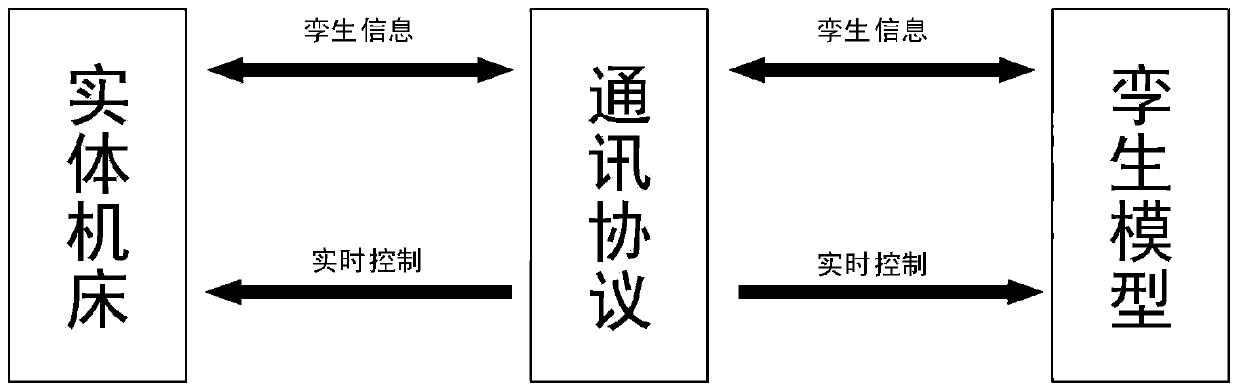

[0021] 2) Establish a digital twin model of a five-axis CNC machine tool: In Flexsim, ProModel, Witness, VisualComponents virtual simulation software, import the twin virtual model established in step 1), and define the kinematics, The visual display of dynamics and monitoring da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com