A kitchen fume waste gas treatment equipment

A waste gas treatment equipment and technology for waste gas treatment, which are used in the removal of oil fume, lighting and heating equipment, household stoves/stoves, etc., can solve the problems of clogging of fume hoods, accumulation in the body, clogging of filter holes, etc., to reduce the probability of clogging , to prevent distortion, easy to stretch the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

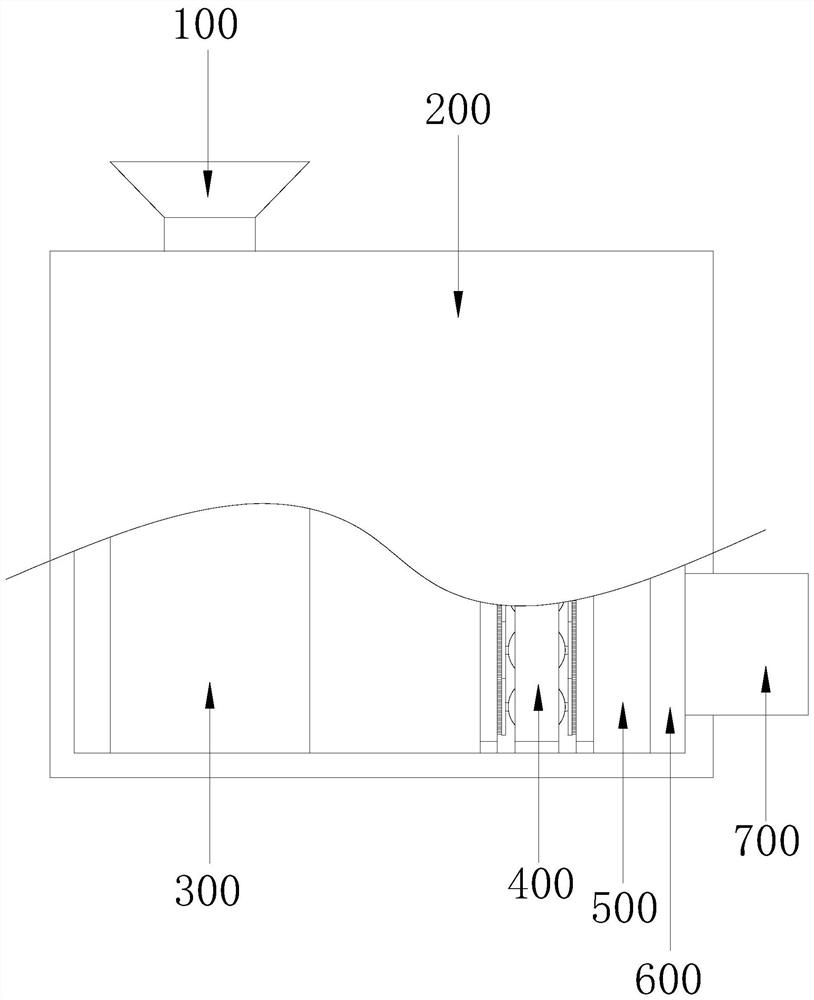

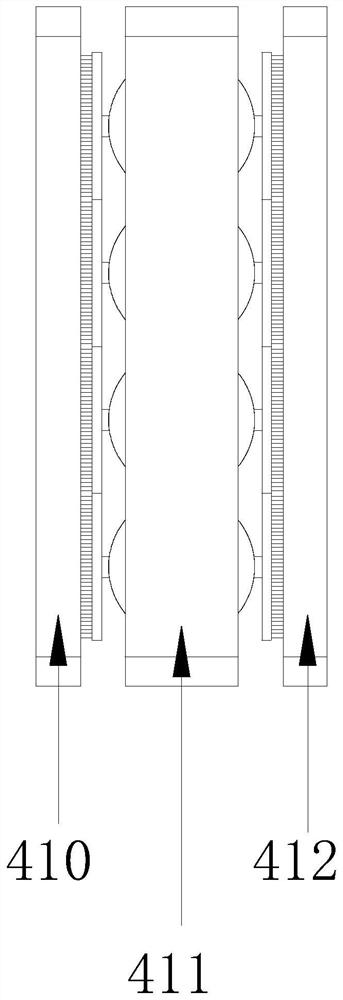

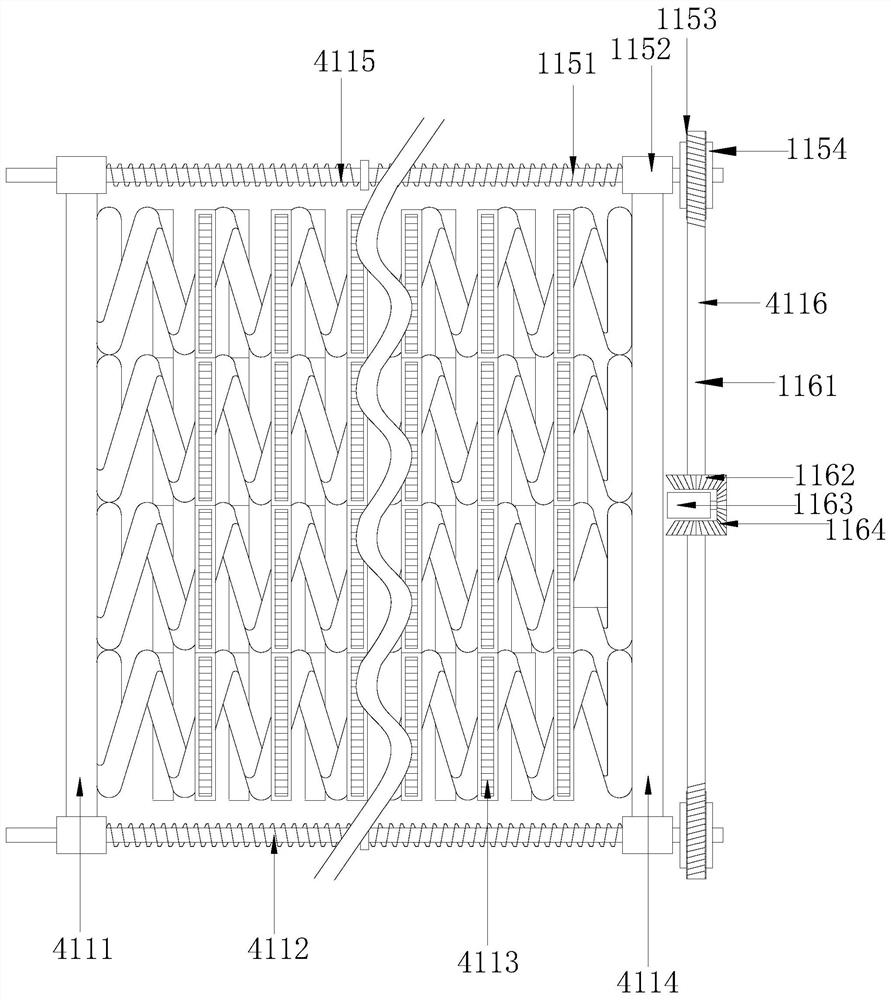

[0030] see Figure 1-3 , the present invention provides a technical solution for kitchen fume and waste gas treatment equipment: its structure includes an intake pipe 100, a waste gas treatment body 200, an L-shaped pipe 300, a fume and waste gas treatment device 400, a fan 500, an activated carbon filter 600, and an air outlet pipe 700, the top of the waste gas treatment body 200 is vertically connected with an air inlet pipe 100, and the air inlet pipe 100 is connected to an L-shaped pipe 300, and the L-shaped pipe 300 is connected to a fan 500 through a lampblack waste gas treatment device 400, and the fan 500 An activated carbon filter 600 is provided on the side away from the lampblack exhaust gas treatment device 400. The activated carbon filter 600 communicates with the air outlet pipe 700, and the air outlet pipe 700 is vertically connected with the side of the exhaust gas treatment body 200. The best setting is to deodorize the exhaust gas, which can discharge fresh a...

Embodiment 2

[0037] see Figure 1-5 , the present invention provides a technical solution for kitchen fume and waste gas treatment equipment: its structure includes an intake pipe 100, a waste gas treatment body 200, an L-shaped pipe 300, a fume and waste gas treatment device 400, a fan 500, an activated carbon filter 600, and an air outlet pipe 700, the top of the waste gas treatment body 200 is vertically connected with an air inlet pipe 100, and the air inlet pipe 100 is connected to an L-shaped pipe 300, and the L-shaped pipe 300 is connected to a fan 500 through a lampblack waste gas treatment device 400, and the fan 500 An activated carbon filter 600 is provided on the side away from the lampblack exhaust gas treatment device 400. The activated carbon filter 600 communicates with the air outlet pipe 700, and the air outlet pipe 700 is vertically connected with the side of the exhaust gas treatment body 200. The best setting is to deodorize the exhaust gas, which can discharge fresh a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com