Method for reducing content of fusidic acid by-product by biotransformation method

A technology for fusidic acid and biotransformation, which is applied in the field of reducing the content of by-products of fusidic acid by biotransformation, can solve the problems of cumbersome chemical synthesis steps, no other bacterial species have been found, and chemical methods are difficult to apply, etc., and achieves good economic efficiency. Value and social benefit, mild cultivation conditions, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

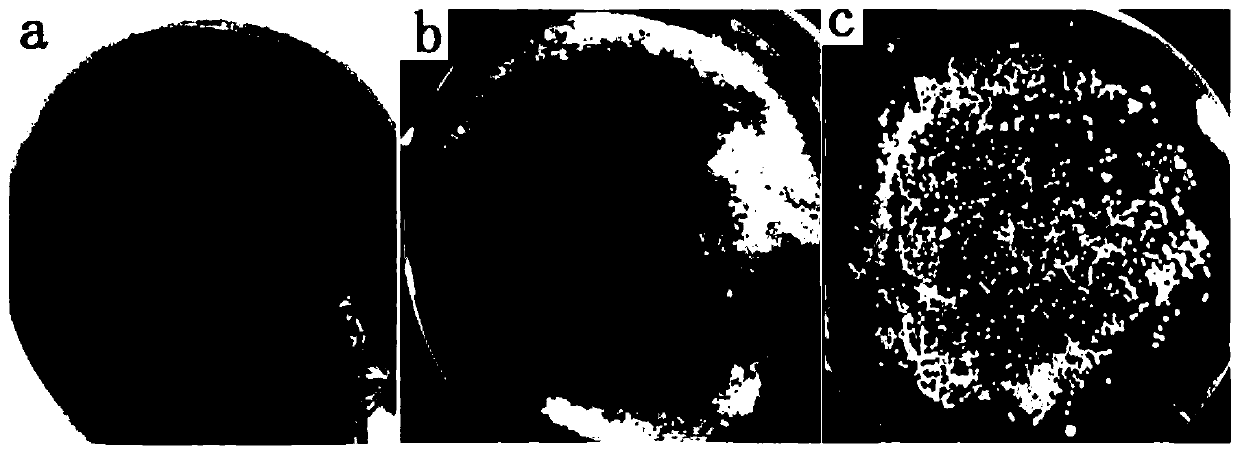

[0034] The preserved Rhizopus niger and Rhizopus oryzae glycerol tubes were respectively coated on the prepared PDA solid medium, incubated at 28 °C for 4-5 days, and then washed with sterile normal saline or 0.5% Tween-80 sterile aqueous solution plate, collect the spores, in 1 ml (10 8 cells / ml) were respectively inserted into the fermentation medium, and co-cultivated at 28 °C and 200 rpm for 24 h with constant temperature shaking and then set aside.

Embodiment 2

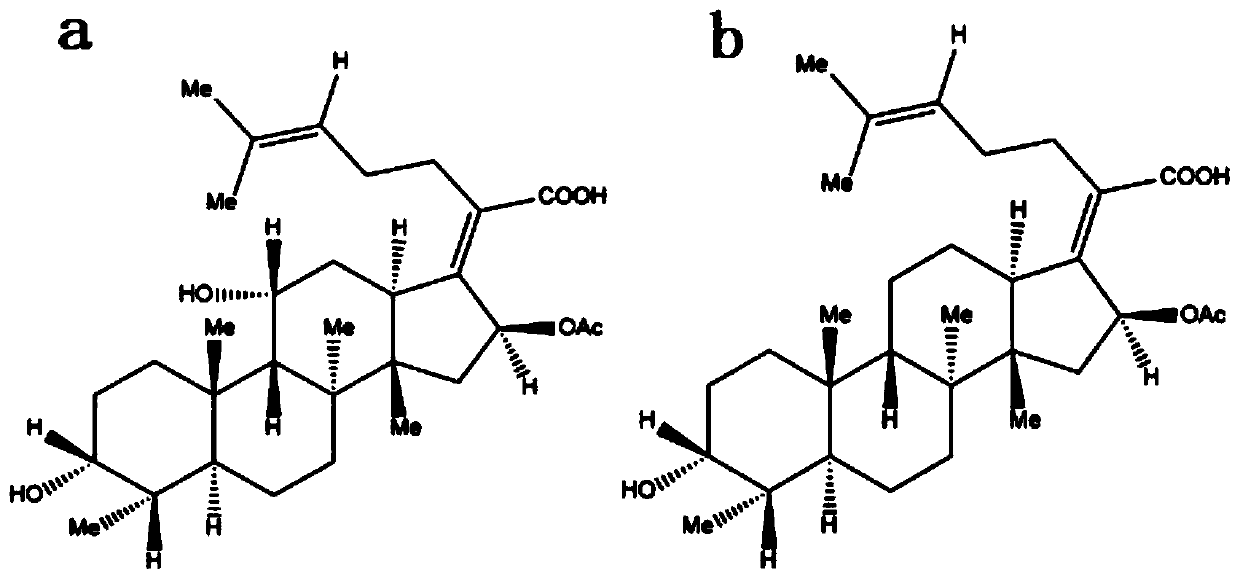

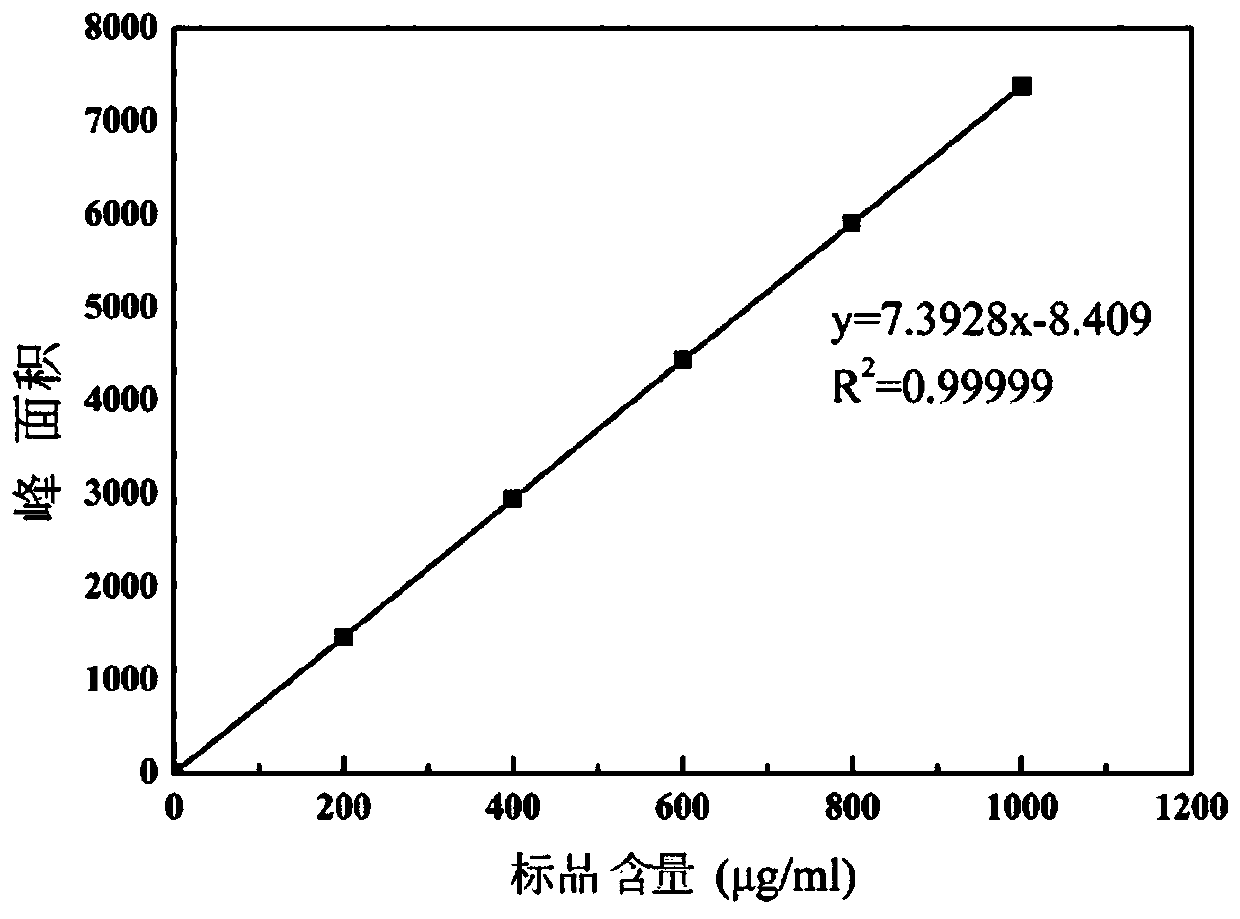

[0036] Prepare PDA solid medium, spread the preserved Fusidia sphaericus glycerol tube on the medium, culture the culture medium for 5-6 d fusidic acid-producing strains into primary seed medium, and cultivate at 26 °C After 72±5 hours, transfer 1% of the inoculum to the secondary expansion medium, culture at 26°C for 25±5 hours, then transfer to the fermentation medium at 10% of the inoculum, and culture at 26°C for 7-8 days , to prepare fusidic acid fermentation broth. After testing, the yield of fusidic acid produced by Fusidia sphaericus fermentation was 3205 μg / ml, and the yield of M impurity was 268 μg / ml (the content was 7.72%).

Embodiment 3

[0038] Collect the fermented fusidic acid fermentation broth, adjust the pH to 3.5-4.0 with dilute hydrochloric acid, let it stand for 30 minutes, and extract it with 4 times the volume of absolute ethanol for 30 minutes, during which the mixture was shaken continuously. After the end, appropriate amount of samples were taken and stored in a refrigerator at 4°C. The fermentation extract was centrifuged, and the supernatant was concentrated by low-temperature rotary evaporation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com