Beer formula and brewing process

A beer and process technology, applied in the field of beer brewing, can solve the problems of insignificant differences in beer taste and serious product homogeneity, and achieve the effects of pure and strong malt aroma, improving fruit flavor and enhancing core competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

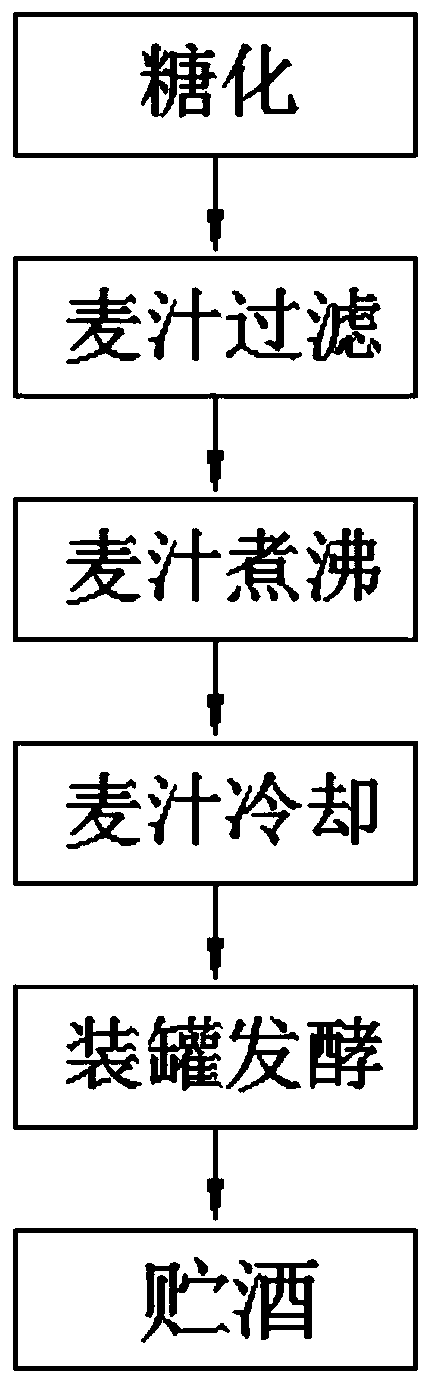

[0031] Such as figure 1 As shown, the present invention provides a kind of beer formula, and beer is made of 2800kg of Australian malt, 1600kg of light-colored wheat malt, 50kg of high-flavored malt, 50kg of Vienna malt, 50kg of light-colored Munich malt, and 50kg of light burnt aroma Malt, 25kg of crystallized malt, 25kg of red malt, 10kg of Cascade fragrant flower, 5kg of Qingdao big flower, 3kg of coriander seed, 3kg of orange peel and 21t of purified water.

[0032] A kind of brewing process of beer, the brewing steps of beer are as follows:

[0033] (1) Saccharification: mix 2800kg of Australian malt, 1600kg of light-colored wheat malt, 50kg of high-aroma malt, 50kg of Vienna malt, 50kg of light-colored Munich malt, 50kg of light caramel malt, 25kg of crystalline malt, 25kg of After the red malt is crushed and mixed, it is added to the mash pot, and 21 tons of pure water is added to mix evenly to form a malt mash. After that, the saccharification reaction is carried out ...

Embodiment 2

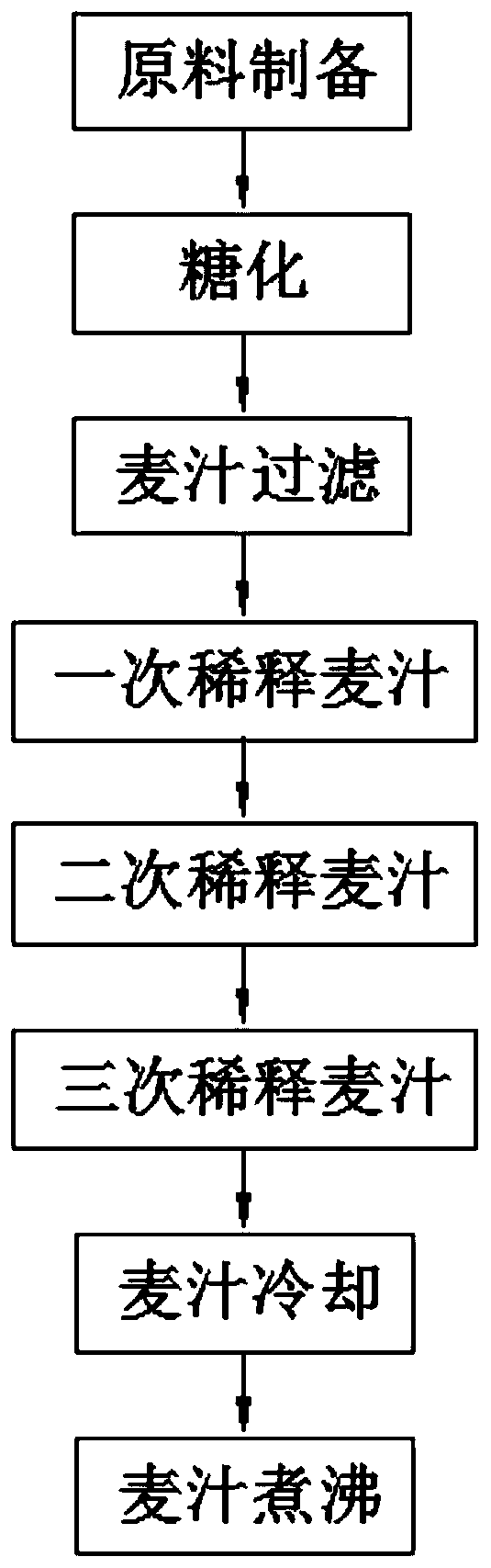

[0042] Such as figure 2 As shown, before the wort is fermented in tanks, the raw materials need to be saccharified to prepare the wort stock solution, and then the wort stock solution needs to be filtered, boiled, and cold cut to obtain the required fermentation stock solution. The specific fermentation stock solution Proceed as follows:

[0043] (1) Preparation of raw materials: 2800kg of Australian malt, 1600kg of light-colored wheat malt, 50kg of high-aroma malt, 50kg of Vienna malt, 50kg of light-colored Munich malt, 50kg of light burnt malt, 25kg of crystalline malt, 25kg The red malt is pulverized and mixed, then added to the mash tun, and 21t of purified water is added, and mixed evenly again to form malt mash;

[0044](2) Saccharification: Put the malt mash in the mash pot for 20 minutes at 50°C for protein rest, heat up to 65°C for 40 minutes for starch hydrolysis, heat up to 72°C for 20 minutes, and pass the iodine test Finish saccharification after heating up to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com