Mold pressing mechanism for aspheric lens

An aspheric lens, molding technology, applied in glass re-molding, glass manufacturing equipment, glass molding and other directions, can solve the problems of long production and processing time, inconvenient operation, low yield, etc., to ensure quality and yield, The effect of prolonging the service life and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

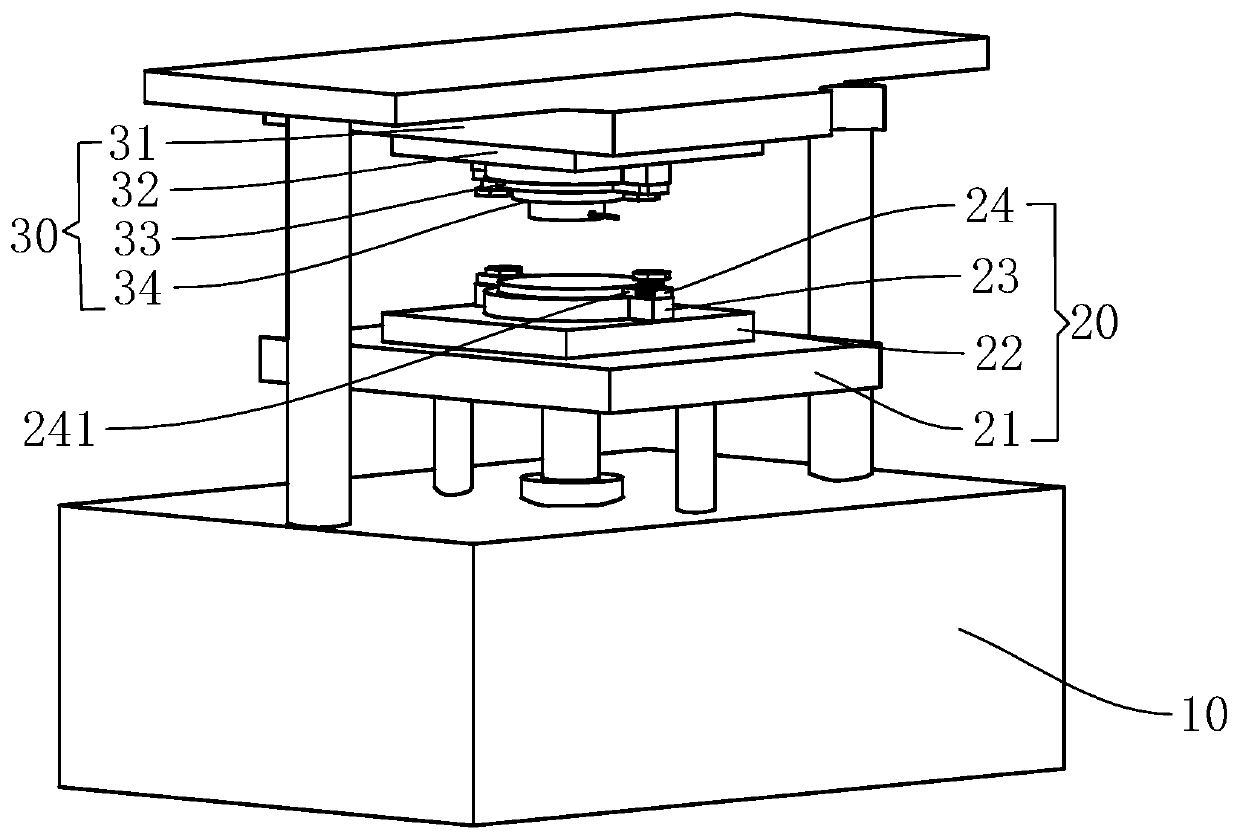

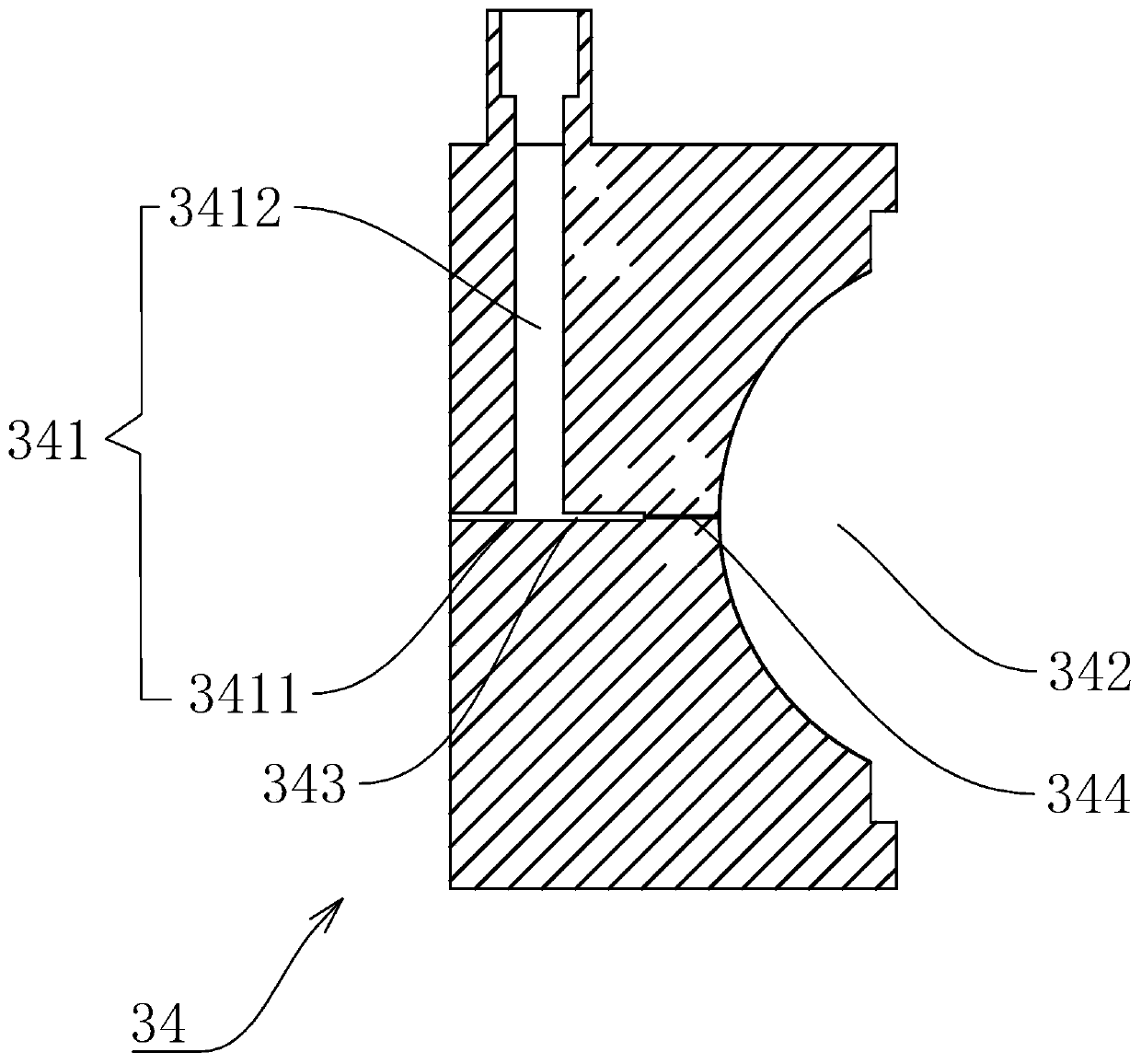

[0022] like figure 1 and figure 2 As shown, the molding mechanism for the aspheric lens includes:

[0023] The workbench 10 is provided with a through hole for telescoping the lifting arm;

[0024] The lower mold mechanism 20 is located on the workbench 10, and the bottom is provided with a lifting arm, which drives the lifting of the lower mold mechanism 20 through a driving mechanism; the lower mold mechanism 20 is sequentially provided with a fixed plate 21, a lower heat shield 22, The second fixed plate 23 and the lower template 24, the second fixed plate 23 and the lower template 24 are detachably fixed, and the lower template 24 is made of tungsten steel material;

[0025] The upper mold mechanism 30 is located directly above the lower mold mechanism 20 and is fixed to the top plate. The lower mold mechanism is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com