Gravity action based strengthened-separation columnar integrated membrane bioreactor

A bioreactor, enhanced separation technology, applied in sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of membrane module pollution easily polluted, easy to destroy the formation conditions of anaerobic nitrification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

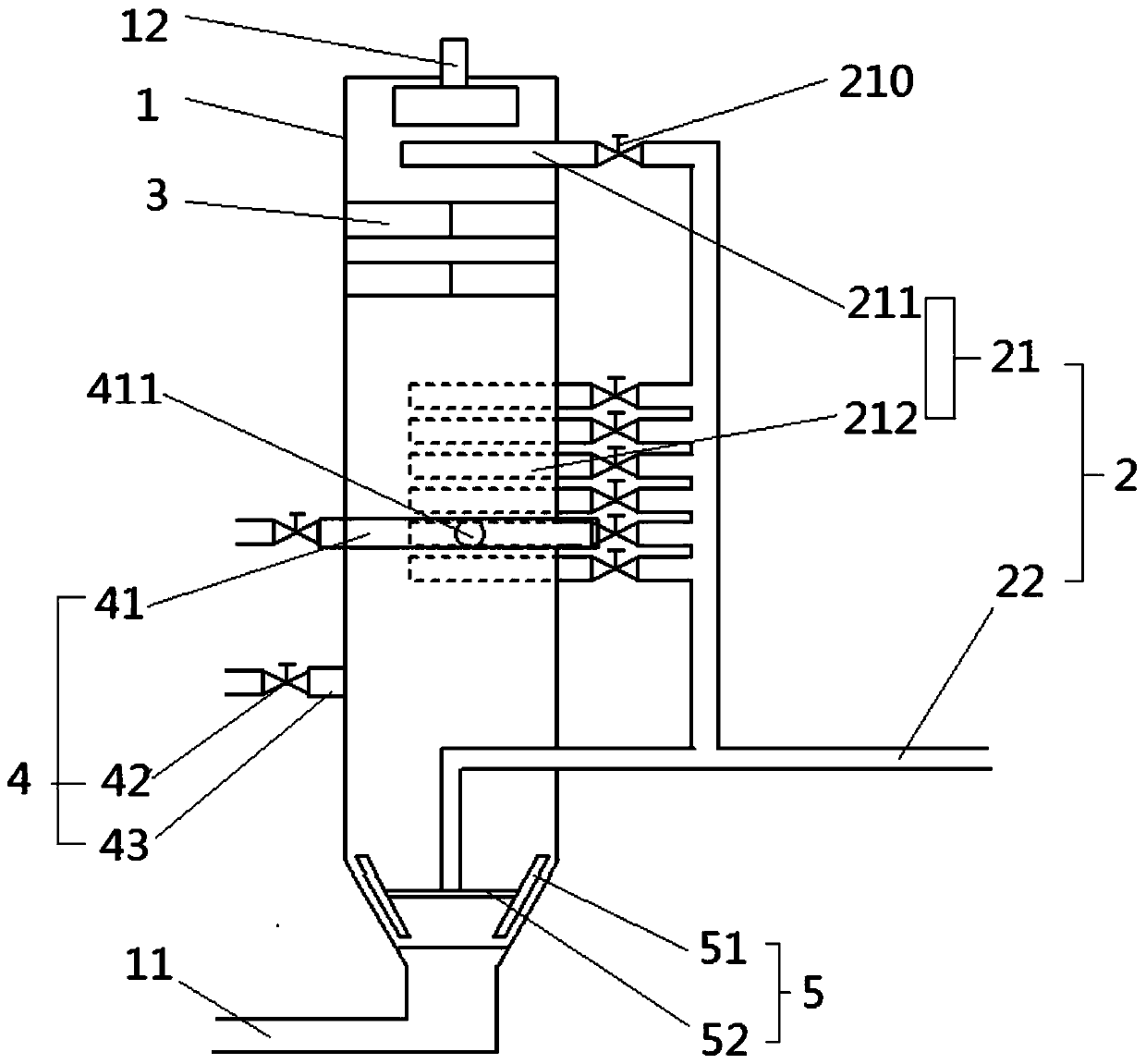

[0026] The enhanced separation columnar integrated membrane bioreactor based on gravity, as shown in the figure, includes a reactor shell 1, the lower end of the reactor shell 1 is provided with a water inlet 11, and the upper end of the reactor shell 1 is provided with a water outlet 12. The reactor shell 1 is a hollow cylinder, and also includes an adjustable aeration device 2. The adjustable aeration device 2 includes an aeration pipe 21 and a gas transmission main pipe 22. The gas transmission main pipe 22 is connected to the aeration pipe 21 and directed to The aeration tube 21 supplies air, and there are many aeration tubes 21. The aeration tubes 21 are inserted into the reactor shell 1 in sequence along the vertical direction and aerate different levels in the reactor shell 1. Each aeration tube Regulating valves 210 are installed on the pipes 21 .

[0027] The aeration pipe 21 includes an upper aeration pipe 211 and a lower aeration pipe 212. There are multiple lower a...

Embodiment 2

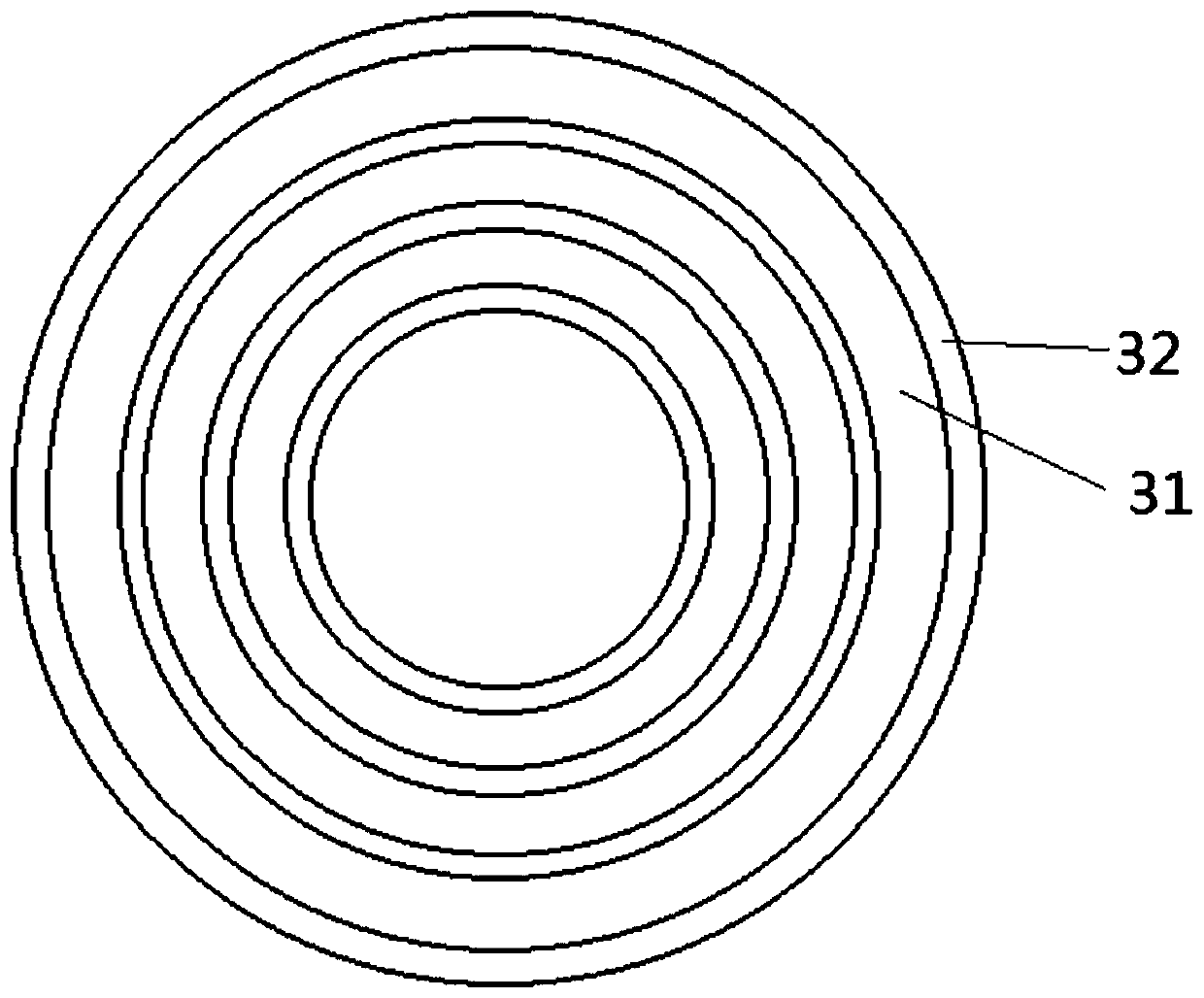

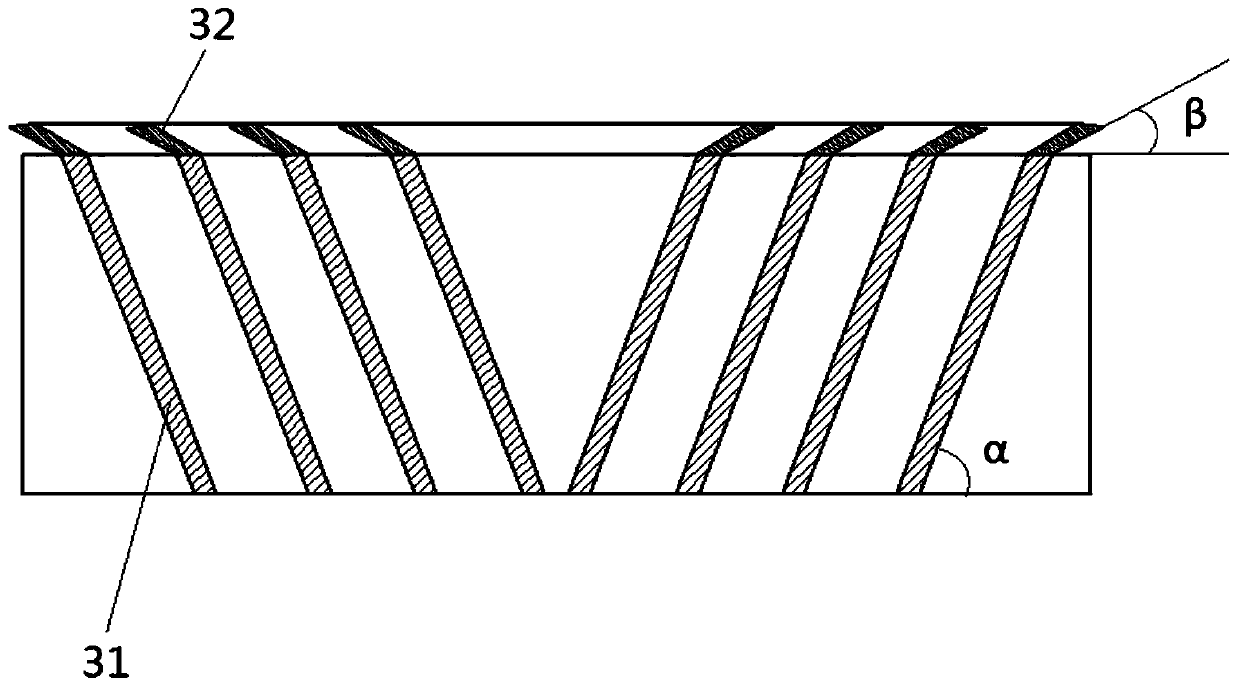

[0030] Same as Example 1, the difference is that a concentric annular separation device 3 is also installed in the reactor shell 1, and the concentric annular separation device 3 includes a plurality of separation rings 31 nested in each other, and the diameter of the ring surface of the separation ring 31 is from top to gradually decreases, the smaller angle between the annulus of the separation ring 31 and the horizontal plane is α, and α is adjustable. The separation rings 31 in the same group of concentric ring separation devices 3 are arranged in parallel, and the distances between the separation rings 31 in the same group of concentric ring separation devices 3 are the same.

[0031] A biofilm is hung on the separation ring 31 .

[0032]Also comprise the retaining ring 32 that is installed on the separating ring 31, the lower ring surface of the retaining ring 32 is affixed to the upper annular surface of the separating ring 31, the diameter of the ring surface of the re...

Embodiment 3

[0036] Same as embodiment 1, the difference is that it also includes a sludge return device 4, the sludge return device 4 includes an inlet pipe 41 and an outlet pipe 42, the outer end of the inlet pipe 41 and the outer end of the outlet pipe 42 communicate with each other, and the inlet pipe The inner end of 41 and the inner end of outlet pipe 42 are all communicated with the inside of reactor shell 1, the inner end of inlet pipe 41 is located at the upper side of lower aeration pipe 212, and the inner end of outlet pipe 42 is located at the upper side from bottom to top. On the horizontal plane where the two lower aeration pipes 212 are located, both the inlet pipe 41 and the outlet pipe 42 are provided with backflow regulating valves 43 .

[0037] The inlet pipe 412 is provided with a plurality of inlets 411 communicating with the inside of the reactor shell 1, and the inlets 411 are distributed around the reactor shell 1 and transport the sludge back inward.

[0038] For c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com