Microphone electrostatic protection structure and electronic equipment

An electrostatic protection and microphone technology, applied in the direction of static electricity, damage caused by electrostatic discharge, electrical components, etc., can solve the problems of destroying the microphone ASIC chip, the product price has no advantage, and it is difficult to automate production. Performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

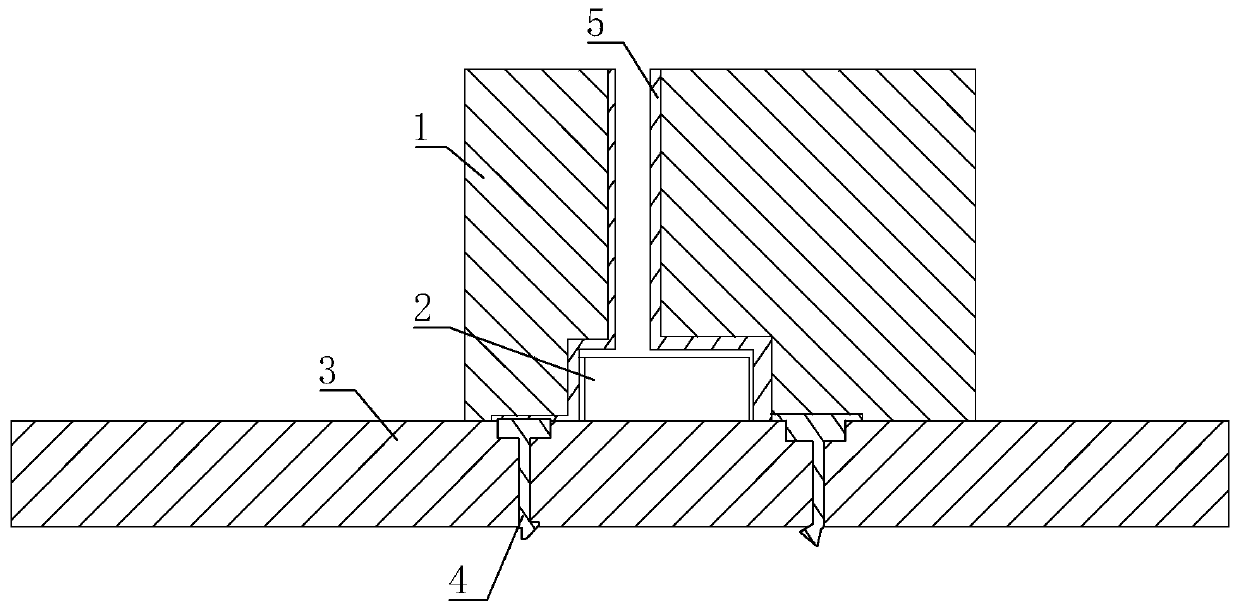

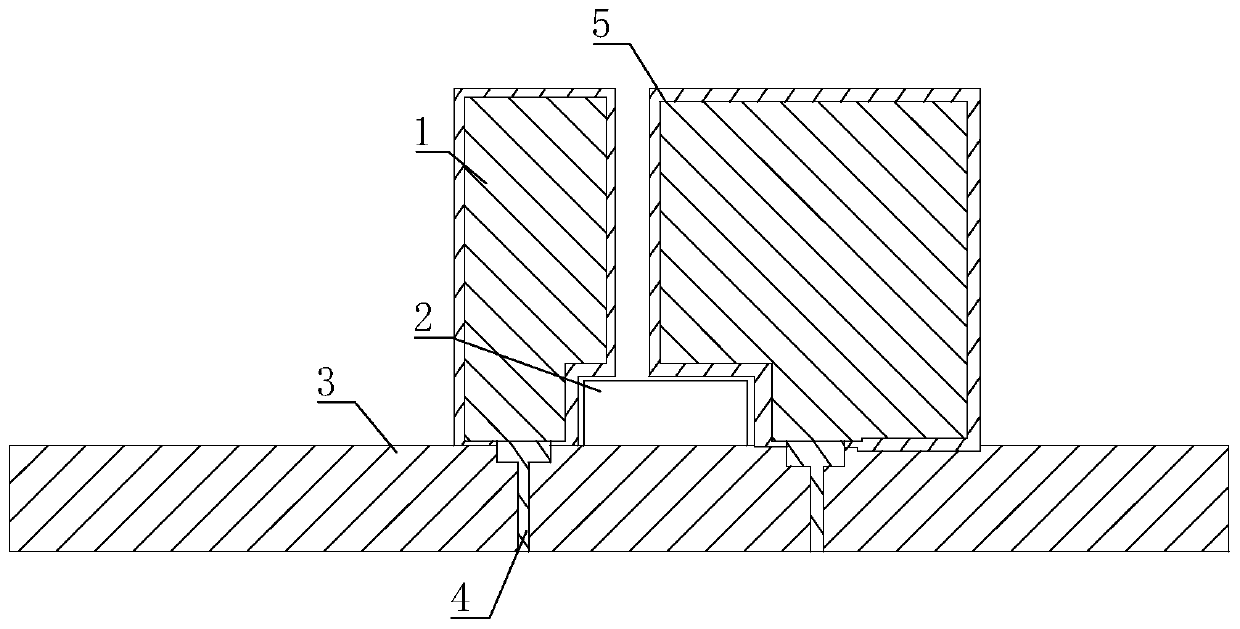

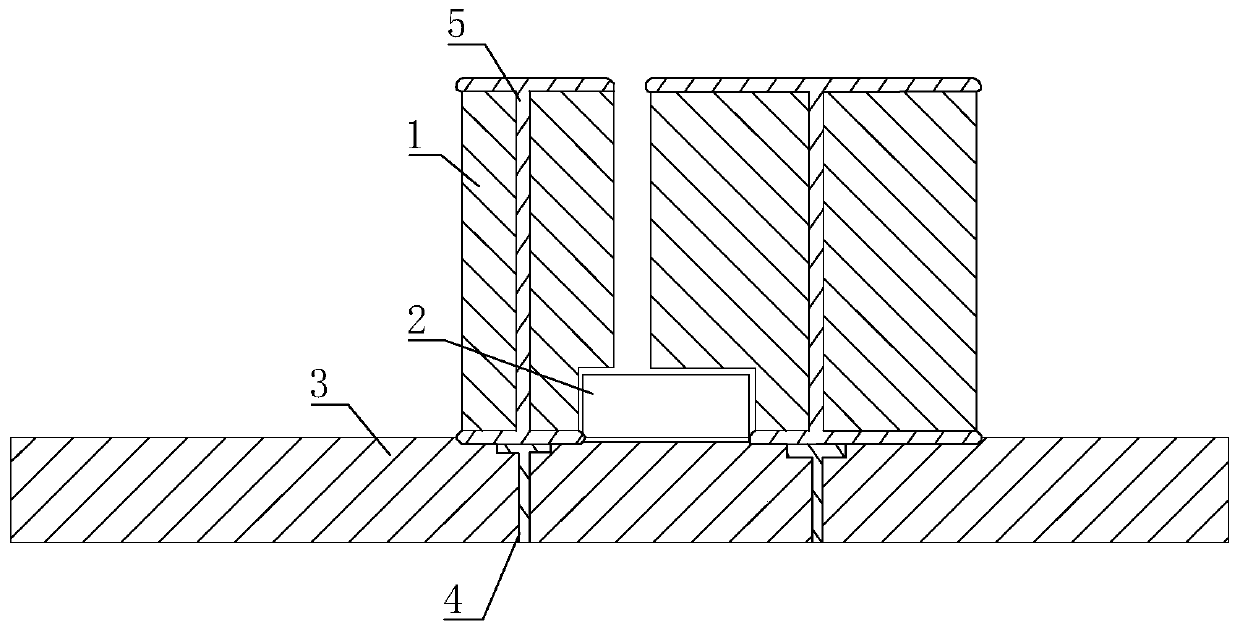

[0027] Such as Figure 1 to Figure 3 As shown together, a microphone electrostatic protection structure includes a circuit board 3 for fixing the microphone 2, the circuit board 3 is provided with a grounding terminal 4, and the outside of the microphone 2 is wrapped with a sealing member 1 for sealing and insulation. In this example, the sealing member is The silicone part made of silicone material is further a rubber sleeve. The sealing part 1 is provided with a passage through the sound hole of the microphone and the outside; 4 Electrically connected to dissipate static electricity.

[0028] The electrostatic protection structure for the microphone of the present invention, by depositing the conductive layer 5 on the sealing member 1, the conductive layer 5 guides the external static electricity to the ground terminal 4 on the circuit board 3, so that the static electricity will not be introduced into the microphone 2, and then the microphone 2 will be protected. In order ...

Embodiment 2

[0037]An electronic device includes a device body and a microphone, and the microphone adopts the above electrostatic protection structure for the microphone. In this embodiment, the electronic devices are electronic devices such as wearable devices and earphones.

[0038] Because of the electronic equipment of the present invention, its microphone utilizes the conductive layer and the sealing member with conductivity to guide static electricity to the ground terminal on the circuit board, effectively protecting the microphone from static electricity and preventing damage to the microphone; the present invention also uses The seal has an electromagnetic shielding function, which reduces electromagnetic interference and interference, and improves the performance of the microphone, thereby improving the performance of the electronic device. Moreover, the invention has low material cost and simple manufacturing process, which reduces product cost and improves competitiveness. Mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com