Circularly polarized coaxial embedded circular waveguide mode exciter

A mode excitation and coaxial waveguide technology, applied in waveguide devices, resonators, electrical components, etc., can solve the problems of complex structure, high assembly precision requirements, low conversion efficiency and mode purity, and solve the problems of dense oscillation spectrum, Effect of Coupling Efficiency Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

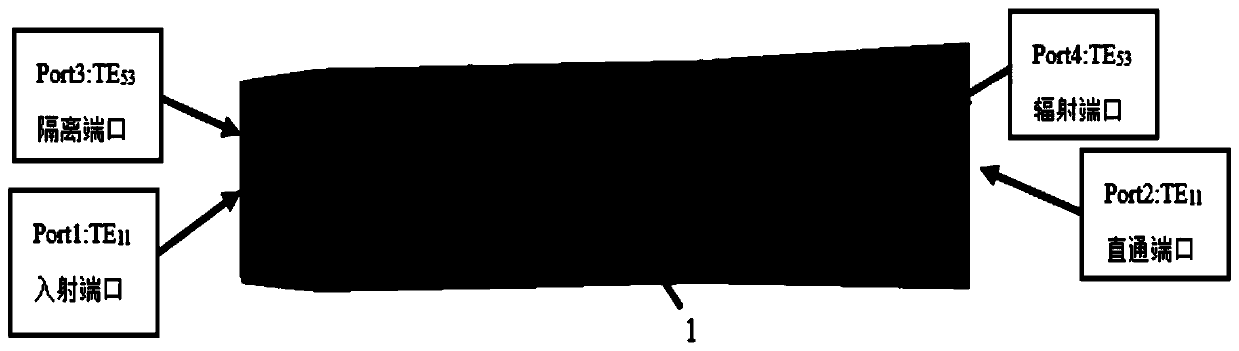

[0027] Embodiment 1: A circularly polarized coaxial embedded circular waveguide mode exciter, see figure 1 As shown, the coaxial embedded circular waveguide mode exciter includes three parts connected in sequence along the axial direction, the first part is to make the TE in the cavity 53 The mode is completely reflected back to the cut-off section of the cavity, which is a "truncated circular" coaxial waveguide structure with a constant radius of the inner conductor and a gradually expanding radius of the outer conductor; the second part is the waveguide resonant section using the Bragg diffraction grating model. It is a uniform open coaxial waveguide structure; the third part is to ensure TE 53 The radiation section where most of the mode power is transmitted by radiation is a section of "truncated circular" coaxial waveguide structure with a constant radius of the inner conductor and a gradually expanding radius of the outer conductor. combine figure 1 , and its structura...

Embodiment 2

[0038] Embodiment 2: further improving the coupling mode and increasing the coupling efficiency. Such as Image 6 As shown, the small hole coupling is changed to the gap coupling, and the dimensions other than the gap are as in the first embodiment. In this embodiment, the gap width is 1.44mm, the gap spacing is 4mm, and the helix angle is 60°. Using the eigenmode design of HFSS, it is found that the coupling efficiency of the slot-coupled coaxial embedded circular waveguide mode exciter is significantly improved compared with the pinhole-coupled coaxial embedded circular waveguide mode exciter. At the same time, the gap opened along the helix further reduces the coaxial TE 53 The component of mode right-handed circular polarization excites the coaxial TE with higher purity left-handed circular polarization 53 mold. Such as Figure 9 As shown, the coupling efficiency of the energy in the slot-coupled circular waveguide into the coaxial resonant cavity reaches 98.01%. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com