Heat transfer performance testing device and testing method thereof for high-temperature heat pipe

A high-temperature heat pipe and heat transfer performance technology, applied in the field of heat transfer, can solve problems such as error, mass flow error of cooling medium, and large total error, and achieve the effects of high precision, simple equipment, and convenient testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

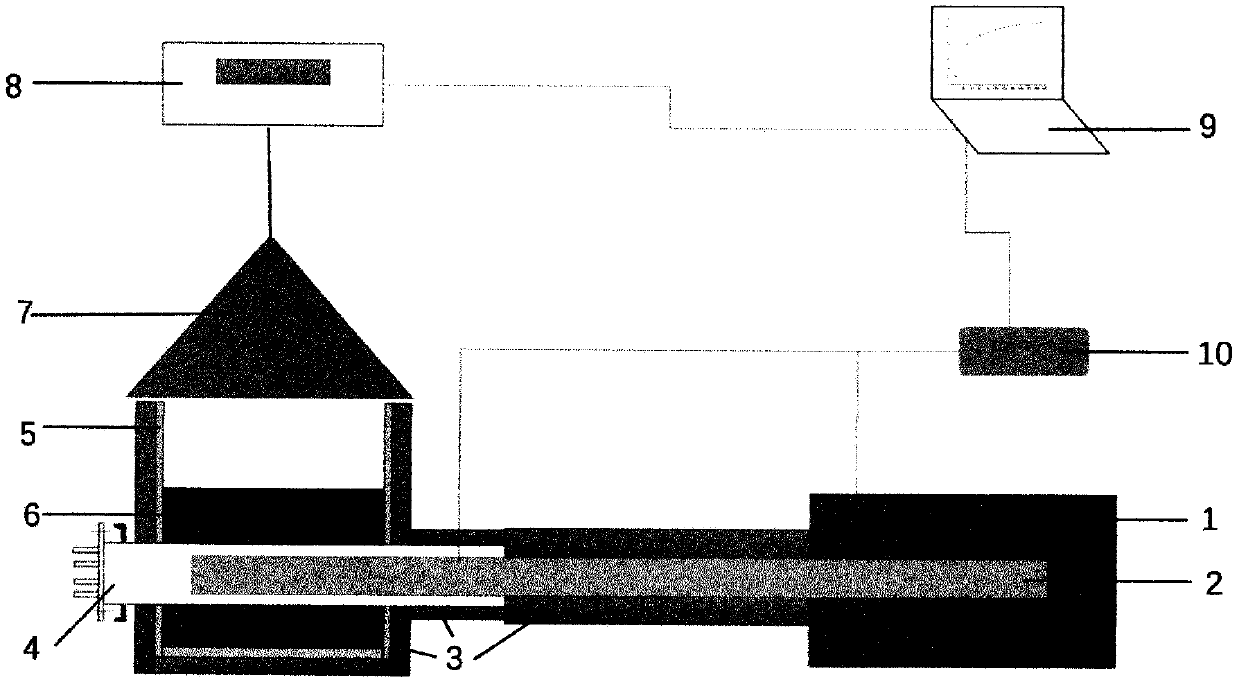

[0049] Such as figure 1 As shown, the present invention provides a novel high-temperature heat pipe heat transfer performance testing device, a high-temperature heat pipe heat transfer performance testing device, including a high-temperature heating device 1, a high-temperature heat pipe 2 to be tested, an insulating material 3, an air gap protective cover 4, Working medium container 5, working medium 6, working medium absorbing device 7, mass measuring system 8, electronic calculator 9, temperature measuring system 10, the condensing section of the high temperature heat pipe 2 to be tested is located in the air gap protective cover 4, to be tested The evaporating section of the high-temperature heat pipe 2 is heated by the high-temperature heating device 1. After the heat is transferred from the high-temperature heating device 1 to the evaporating section of the high-temperature heat pipe 2 to be tested, it is transferred from the evaporating section of the heat pipe to the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com