Special four-way coaxial valve for inner cooling of main shaft of machine tool

A technology of machine tool spindles and coaxial valves, which is applied in the direction of multi-way valves, valve details, valve devices, etc., can solve the problems of affecting the processing rhythm, pollution of the positioning surface, ticking water at the end of the tool, etc., to improve the service life of the pump and the processing quality , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

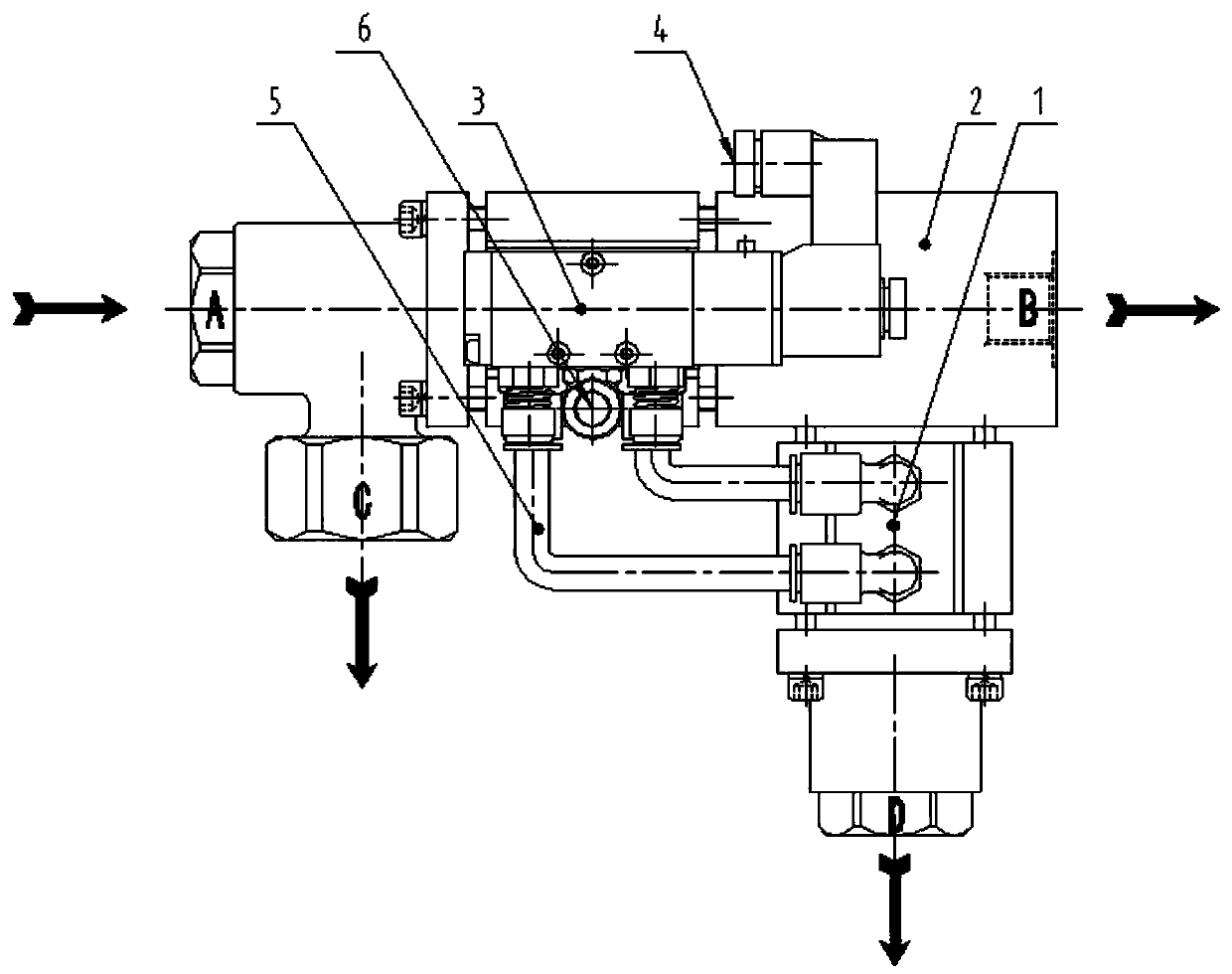

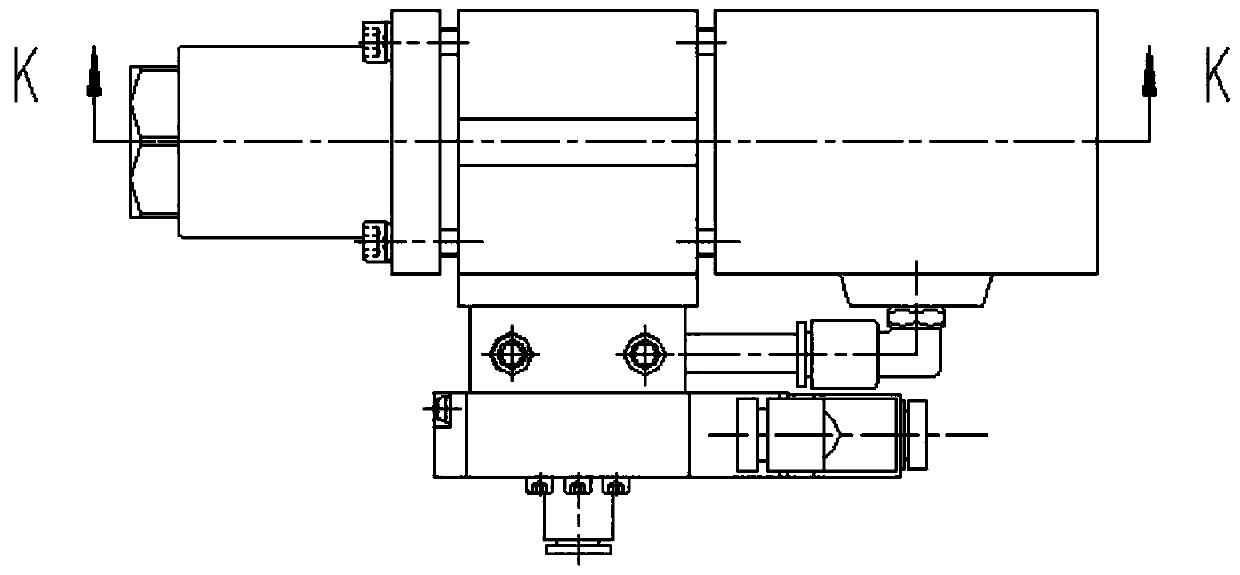

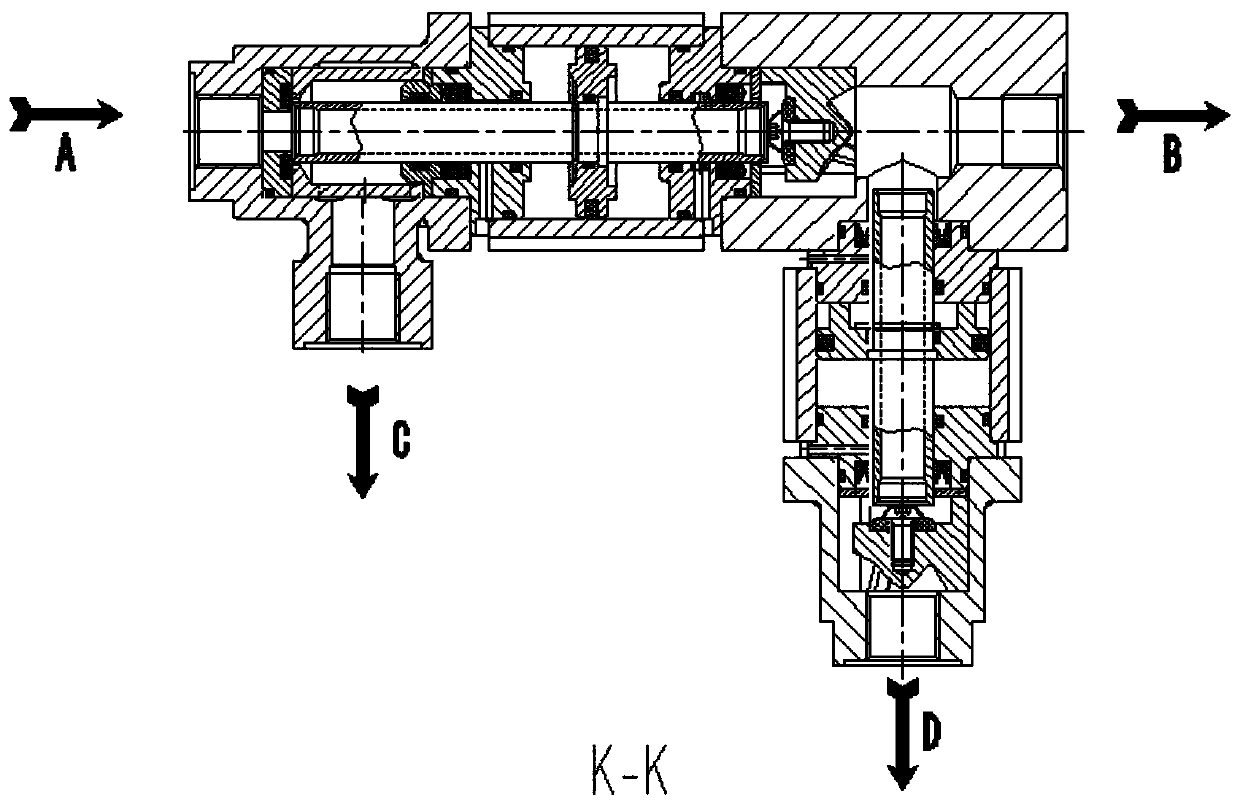

[0028] Attached below Figure 1-5 The specific embodiment of the present invention will be further described.

[0029] The special four-way coaxial valve for the internal cooling of the machine tool spindle includes a manifold valve block 2, a two-position two-way coaxial valve insert 1 is installed under the manifold valve block 2 through screws, and the left side of the manifold valve block 2 The two-position three-way coaxial valve plug-in 3 is installed through screws, and the two-position three-way coaxial valve plug-in 3 is provided with a control air interface 6 and a connection terminal 4. The two-position three-way coaxial valve plug-in 3 and the two-position two-way The shaft valve inserts 1 communicate with each other through the air pipe 5 .

[0030] The two-position two-way coaxial valve insert 1 includes a two-way cylinder body 101, and the inner cavity of the two-way cylinder body 101 is sealed and connected with an upper bushing 110, a vertical piston 102, a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com