Compensation type seal plug valve

A plug valve and compensation technology, applied in the field of plug valves, can solve problems such as seal failure and achieve the effect of increasing the specific pressure of the seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

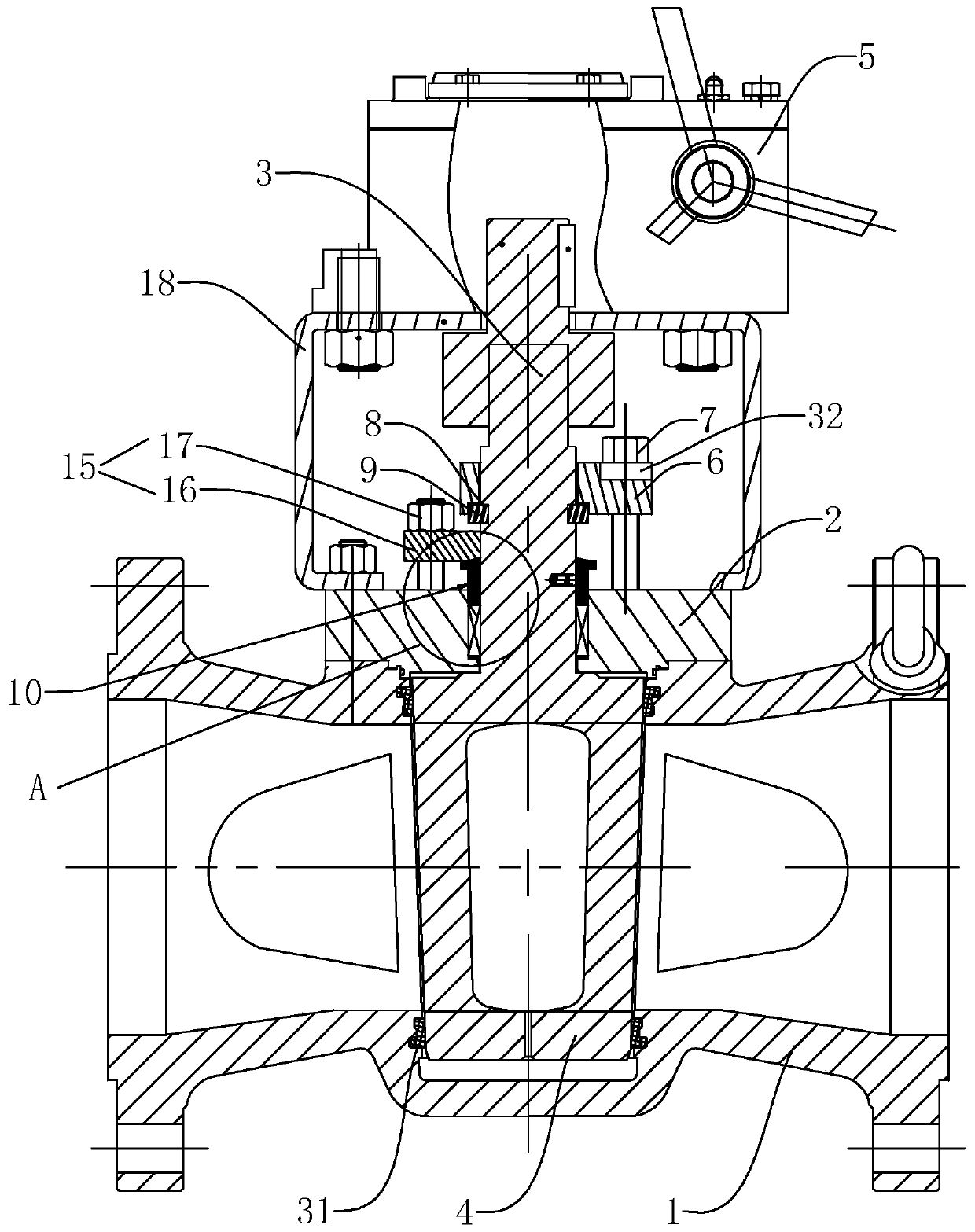

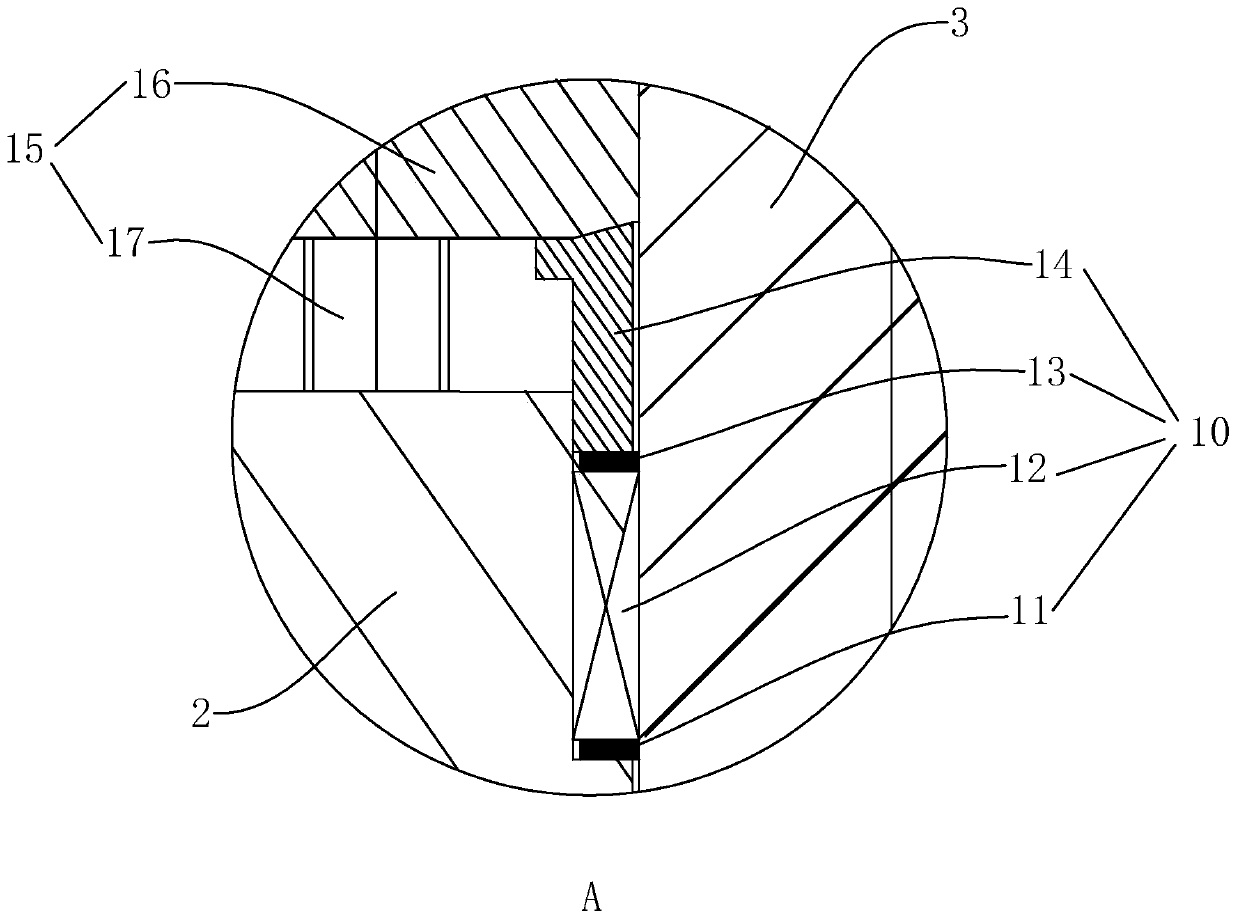

[0025] Such as Figure 1-Figure 2 As shown, a compensable sealing plug valve includes a valve body 1, a valve cover 2 and a valve stem 3. The valve body 1 is provided with a valve cavity communicating with the inlet end and the discharge end, and the valve stem 3 is inside the valve cavity. A plug body 4 is provided at one end of the valve body, and a bushing 31 is provided between the plug body 4 and the valve body.

[0026] The end of the valve stem 3 away from the plug body 4 is key-connected with a driving device 5 capable of driving the valve stem 3 to rotate. One end of the valve stem 3 outside the valve body 1 is provided with an adjusting pressure plate 6 , and one side of the adjusting pressure plate 6 is pierced with a first fastener 7 , and one end of the first fastener 7 is threadedly engaged with the valve cover 2 .

[0027] After long-term use of the plug valve, the sealing surface of the bushing 31 and the plug body 4 will be worn, resulting in an increase in t...

Embodiment 2

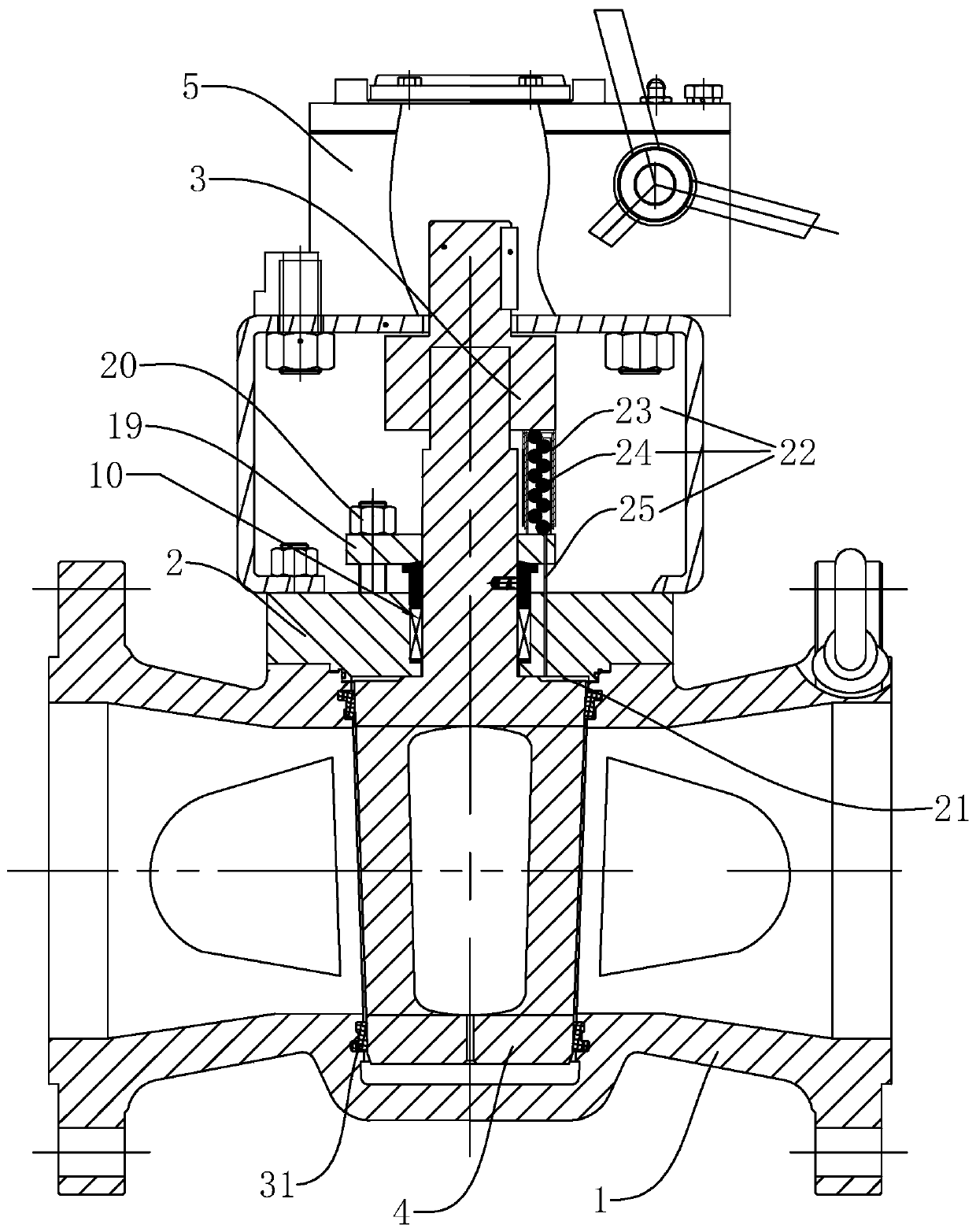

[0039] The difference from the embodiment is: as Figure 3-Figure 5 As shown, one end of the valve stem 3 outside the valve body 1 is fixedly connected with a sealing compensation pressure plate 19 , and the bottom of the sealing compensation pressure plate 19 is in contact with the upper surface of the sealing packing assembly 10 . One side of the sealing compensating pressure plate 19 is pierced with a third fastener 20 , and one end of the third fastener 20 is screwed into the valve cover 2 .

[0040] By setting the sealing compensation pressure plate 19 and the third fastener 20 above, when one end of the third fastener 20 is screwed into the valve cover 2 to reduce the distance between the sealing compensation pressure plate 19 and the valve cover 2 . It can synchronously drive the valve stem 3 and the plug body 4 at one end of the valve stem 3 to move towards the bushing 31 to increase the sealing contact surface between the plug body 4 and the bushing 31 and increase th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com