Device and method for inspecting fuel injection status of fuel injector in generator set target shooting test

A generator set and fuel injector technology, which is applied to fuel injection devices, engine testing, measuring devices, etc., can solve problems such as inability to inspect, limited observation time, and inability to install and seal the observation port.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

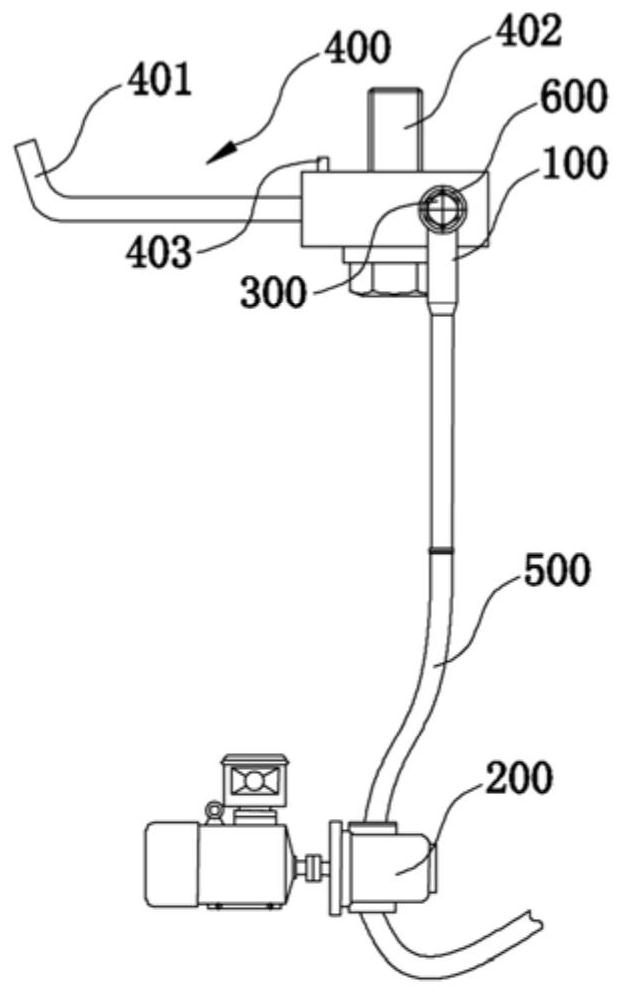

[0033]In this embodiment, preferably, an indirect observation component is also included, which is used to observe the fuel injection status of the fuel injector, and can indirectly observe the fuel injection status of the fuel injector, which solves the problem of inability to Issues with direct viewing of its fuel injection condition; alternatively, indirect viewing of components Two possible implementations are as follows:

[0034] The first type, the indirect observation component includes a reflector, which is set at the observation port of the unit. By adjusting the angle and position of the reflector, the inspector can clearly observe the fuel injection status of the fuel injector from the reflector (ejection The oil beam accurately enters the oil inlet of the piston).

[0035] The second type, the indirect observation component includes a camera and an observation screen. The camera is installed at the observation port of the unit. By adjusting the angle, position and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com