A building formwork fastening kit

A building formwork and fastening technology, which is applied in the field preparation of buildings and building components, and building construction, etc., can solve the problem of steel cofferdams, large formworks whose stability and safety cannot be guaranteed, low work efficiency, time-consuming and labor-intensive problems, etc. Can not meet the template and other problems, to achieve the effect of ensuring stability and safety, cost saving, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

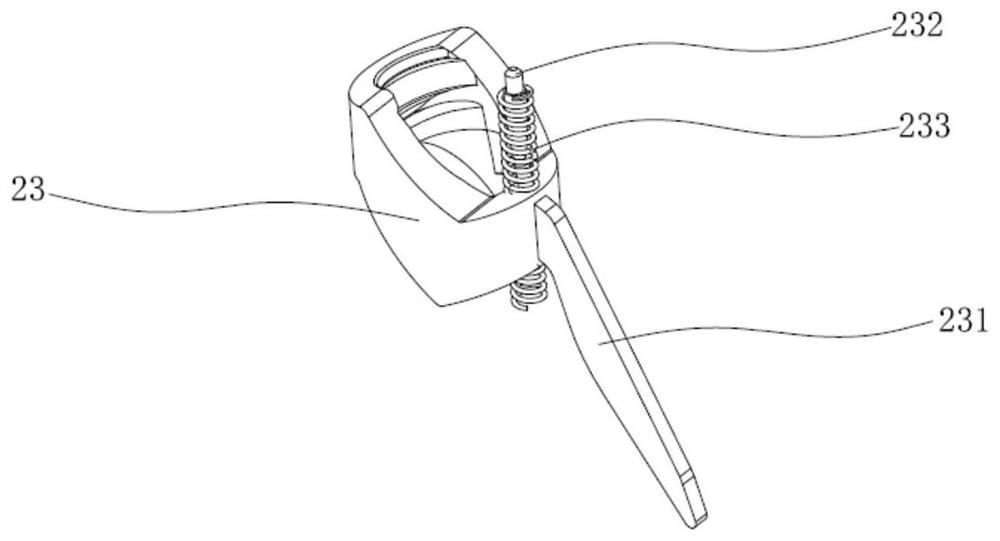

[0025] Such as Figure 1 to Figure 7 As shown, a building formwork fastening kit in this embodiment includes a threaded tie rod 1 and a first locking part 2 and a second locking part 3 installed at both ends of the threaded tie rod 1 . Among them, the threaded tie rod 1 has an integrated structure, and threads are provided on the rod walls at both ends, and in the building formwork fastening kit, the threaded tie rod 1 can be selected according to the specific construction needs. The locking part is installed at the distance of the threaded tie rod 1, and the distance is indicated by digital engraving or punching on the threaded part.

[0026] Specifically, one end of the threaded tie rod 1 is hexagonal, with sharp edges rounded, and the other end is hemispherical, with a central hole for positioning in the middle. The set thread is a left-h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com