Composite foundation-bucket offshore wind power foundation with piles distributed in bucket and construction method

A composite foundation, offshore wind power technology, applied in infrastructure engineering, construction and other directions, can solve the problems of increased barrel foundation weight and fan load, inability to achieve one-step installation, large tilt deformation, etc., to save basic manufacturing costs, The effect of solving the problem of foundation deformation and reducing the manufacturing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

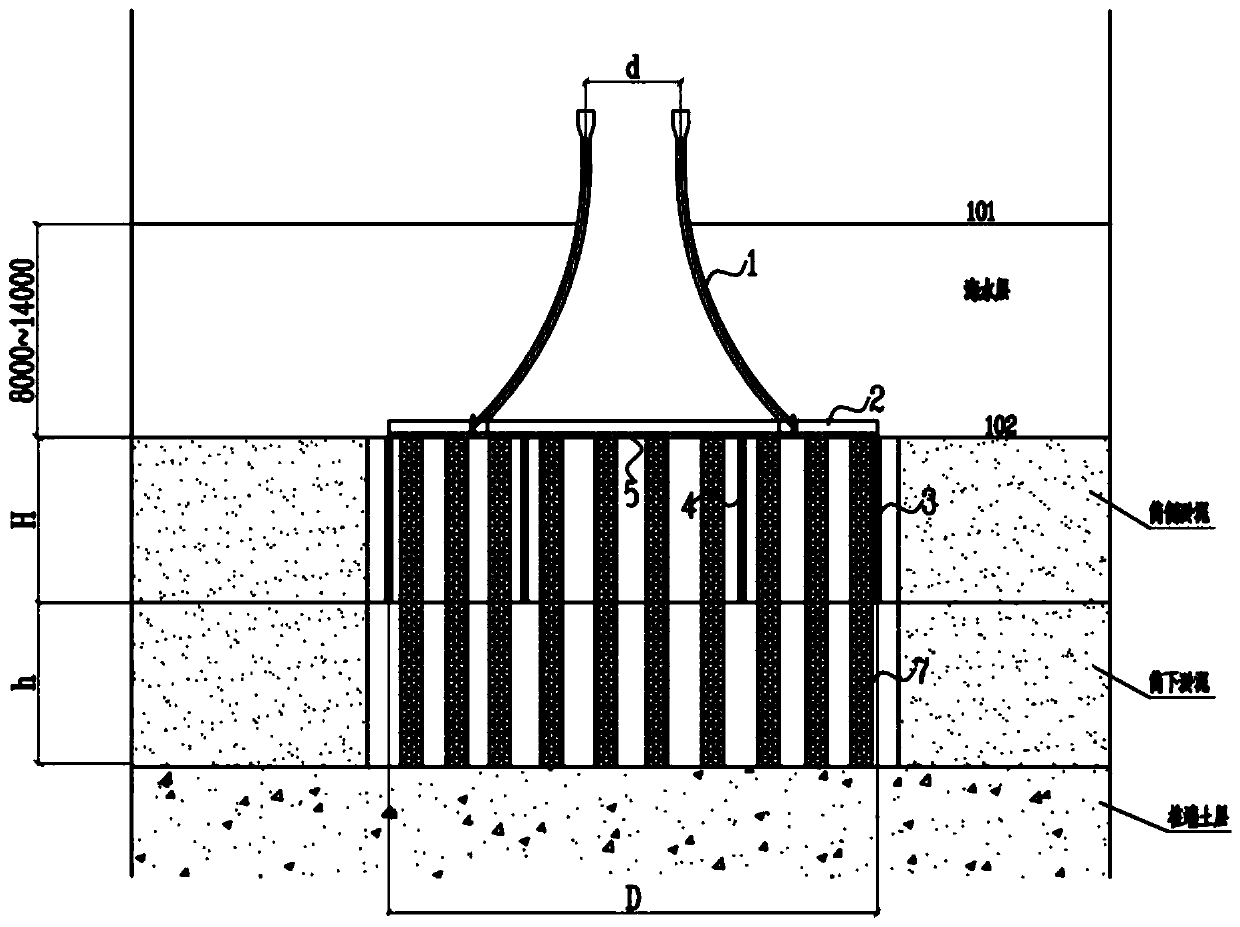

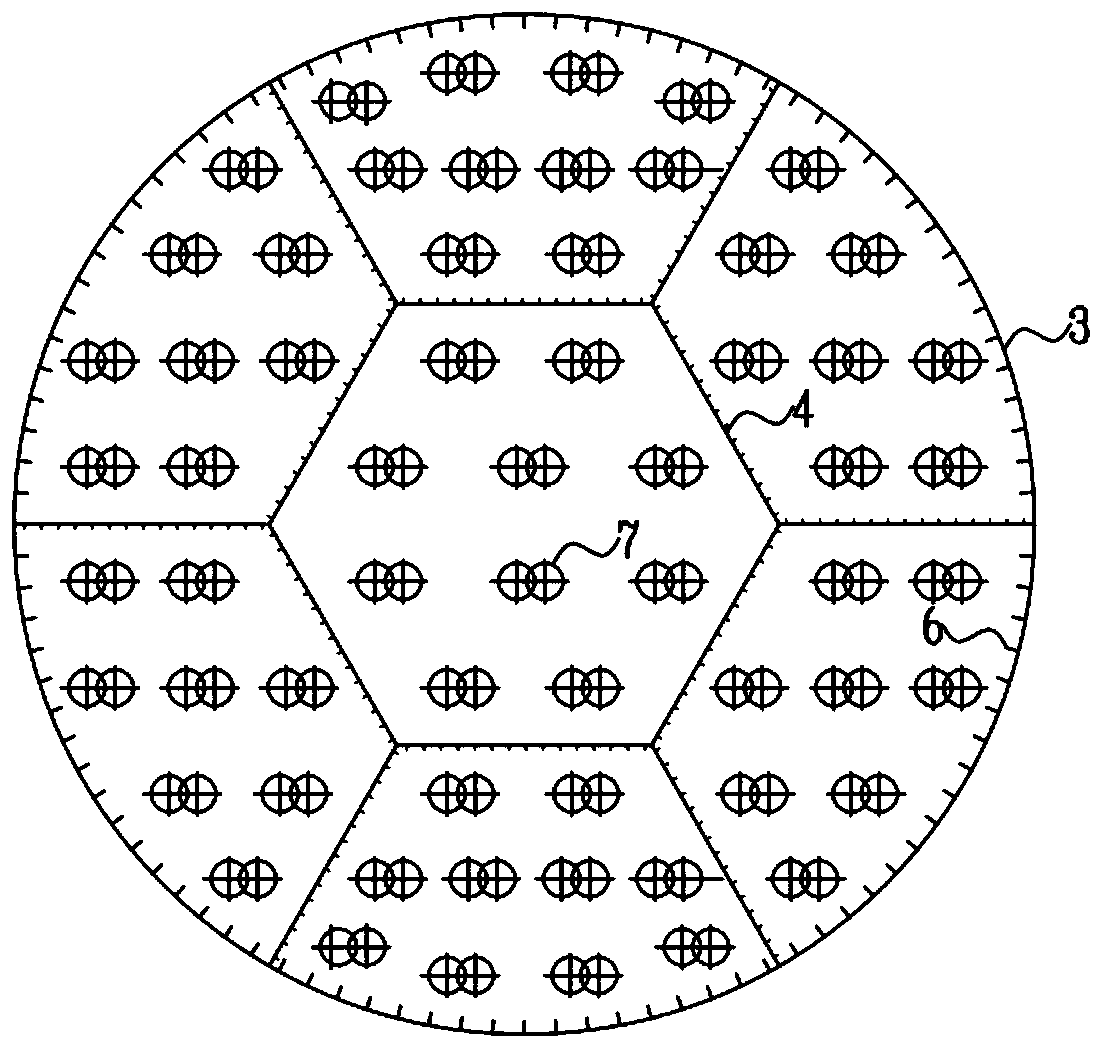

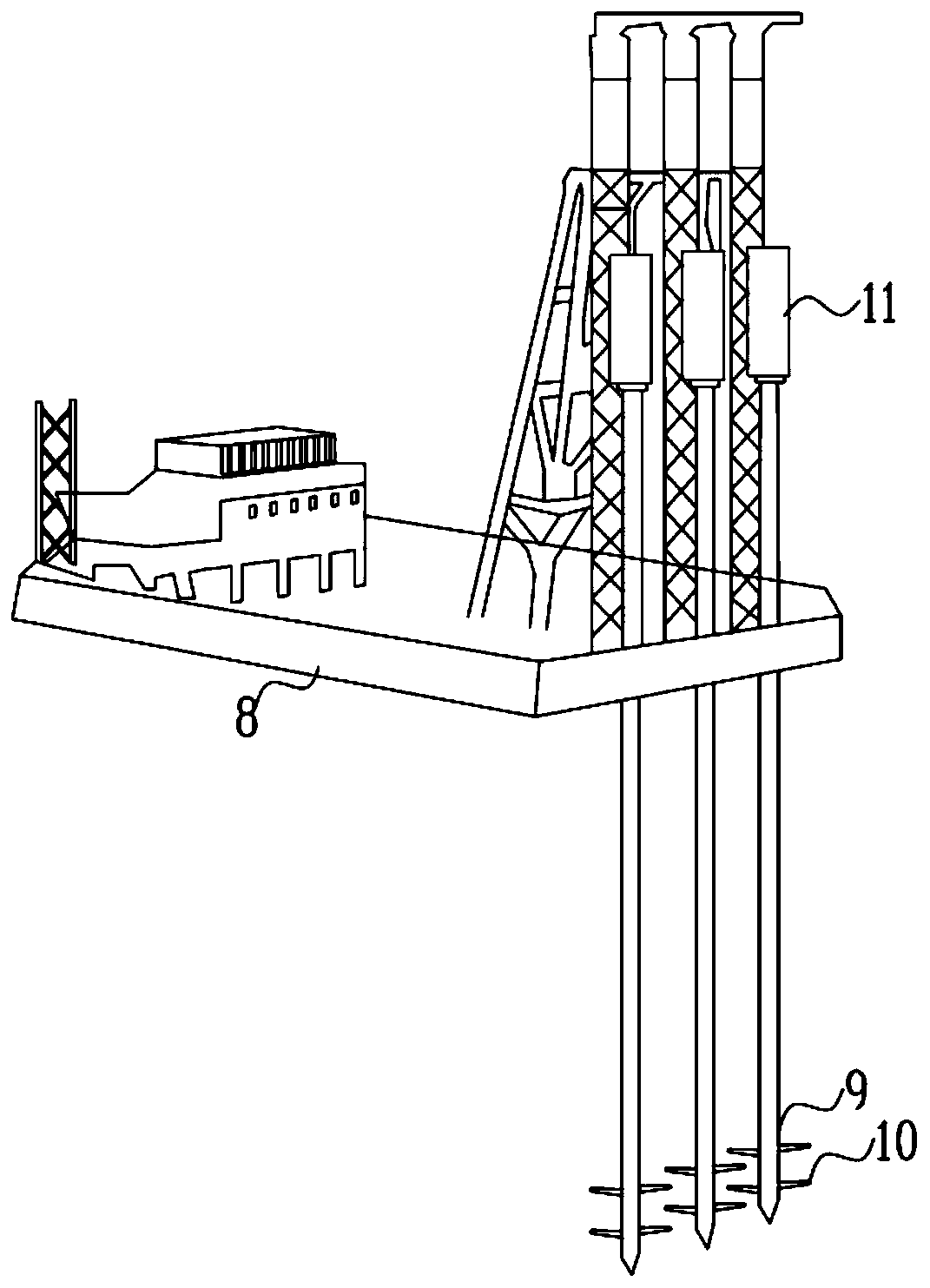

[0025] like Figure 1-3 As shown, a composite foundation with piles in a cylinder-tube offshore wind power foundation of the present invention includes a concrete transition section 1, a composite cylinder foundation and a concrete circular bottom plate 2. The concrete transition section 1 is an internal cavity structure, and the wall thickness can be adjusted. Freely selected, not less than 0.5m, steel bars are arranged in the concrete to enhance its tensile strength, the diameter of the upper opening can be adjusted according to the diameter of the tower, so that the concrete transition section 1 can be docked with the tower; the lower end of the concrete transition section 1 is provided with a composite tube For the foundation, a concrete circular bottom plate 2 is arranged between the concrete transition section 1 and the composite cylindri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com