Material taking device in electroplating process of SMD resistor

A technology of electroplating process and chip resistors, which is applied in the direction of electrolysis process and electrolysis components, can solve the problems that cannot meet the high-efficiency production needs of factories, and achieve the effects of preventing scattering, thorough material removal, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

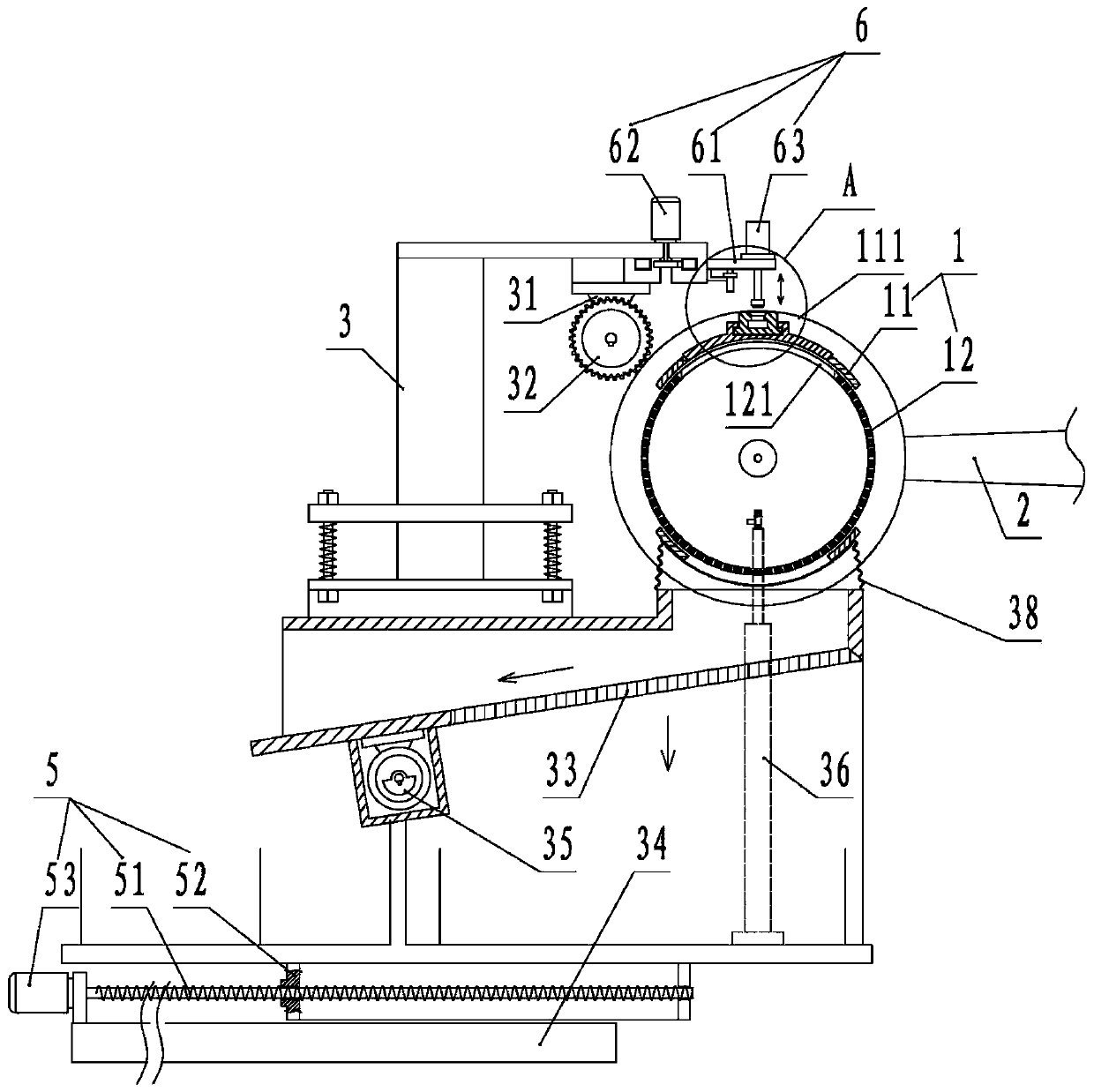

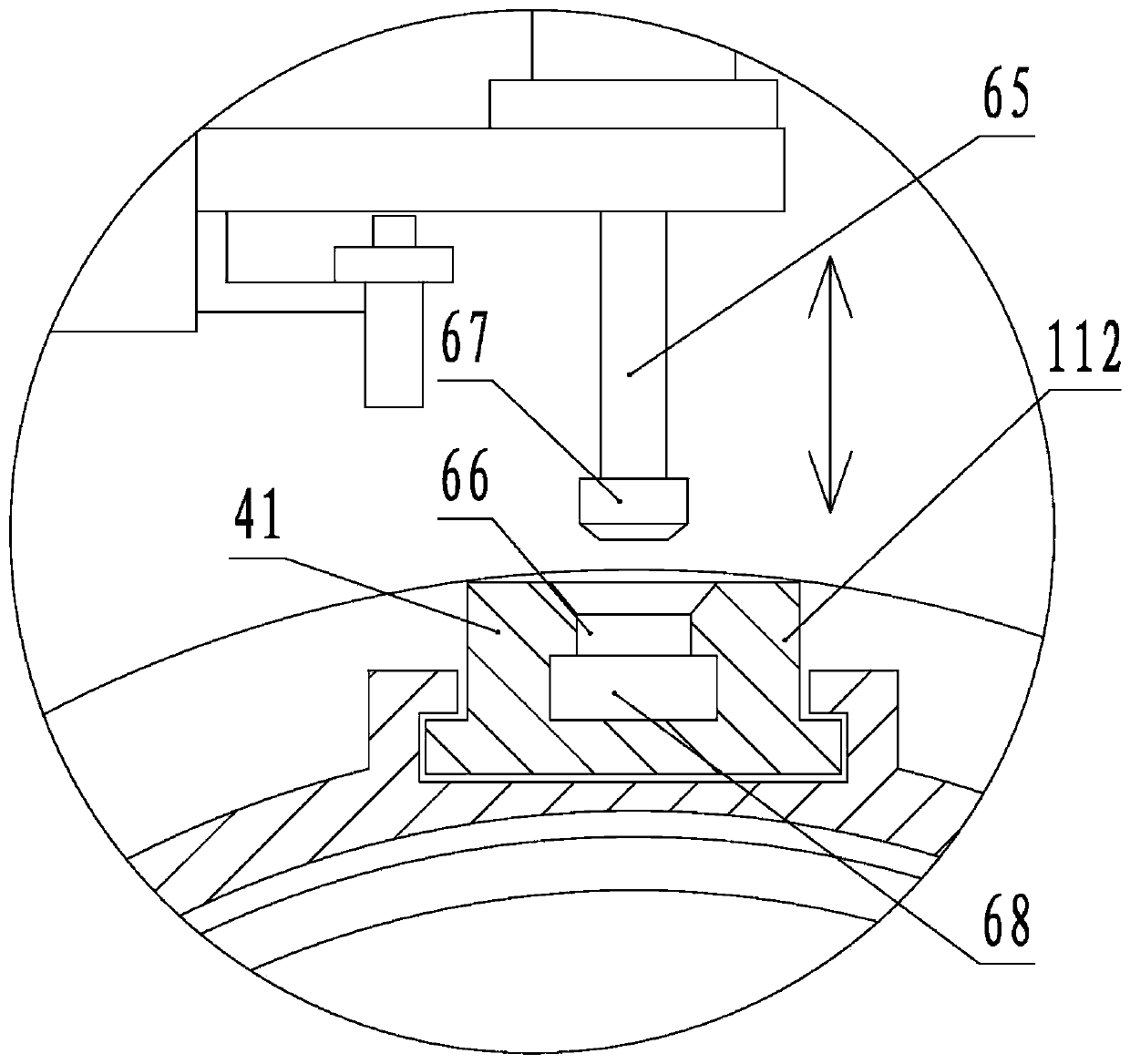

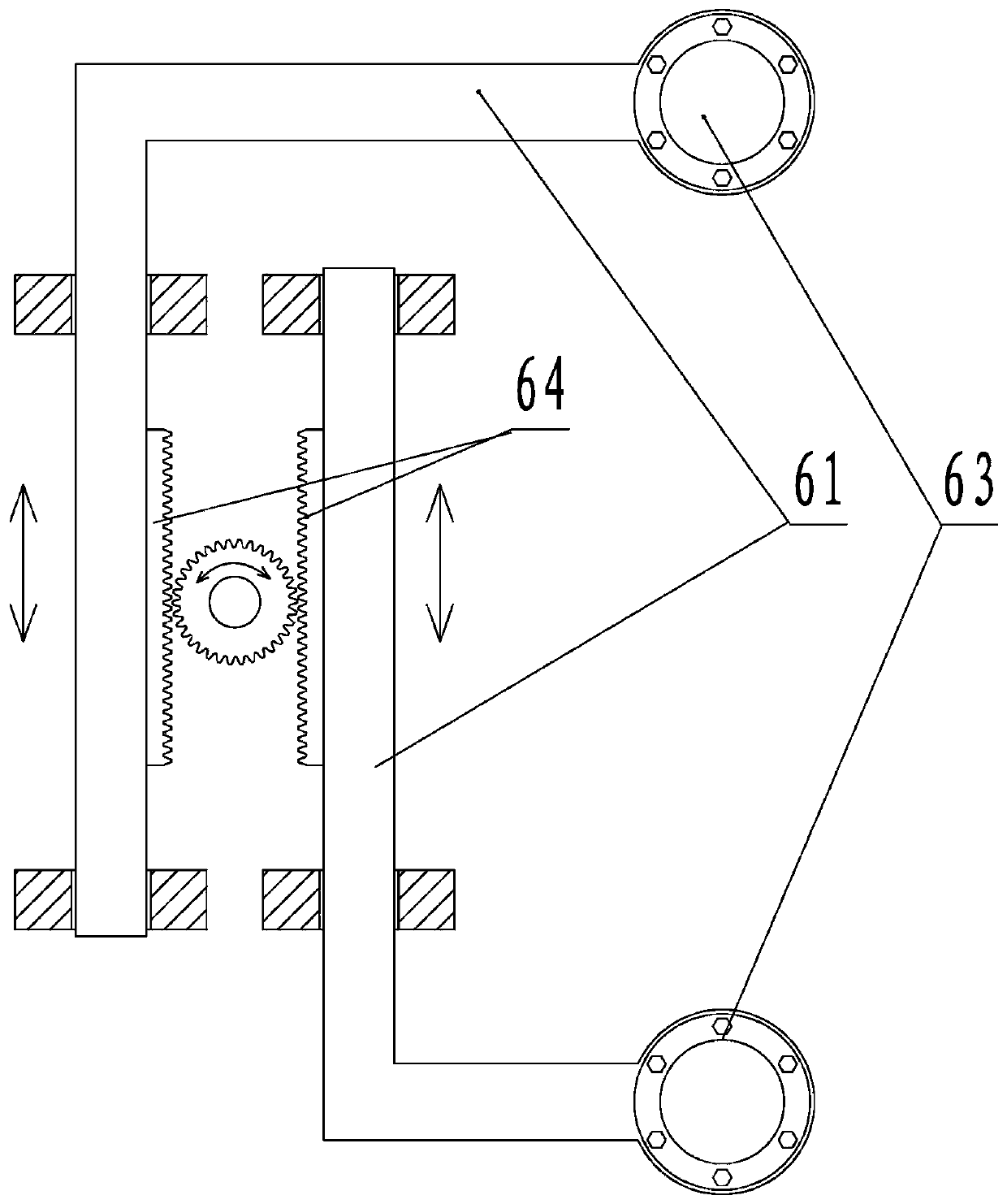

[0029] like Figure 1-8 Shown, the specific structure of the present invention is: a kind of pick-up device in the patch resistance electroplating process, and it comprises pick-up device, body, feeding device; Frame 3, described drum 1 comprises the cylindrical outer tube 11 of loose fit, inner tube 12, and it is made of plastic material, and described outer tube 11 can rotate around the horizontal axis and erect on the drum bracket 2, and drum bracket 2 can The drum 1 is inserted and taken out from the electrolyte, and the two ends of the outer cylinder 11 are coaxially provided with an outer cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com