Strengthened microcrystalline glass with high-pressure stress layer depth and preparation method thereof

A technology of stress layer depth and glass-ceramics, which is applied in the field of glass strengthening, can solve the problems of low stress and restricting the drop resistance performance of lithium-aluminum-silicon chemically strengthened glass, achieve less stress relaxation and improve the intrinsic network structure strength , the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2-6

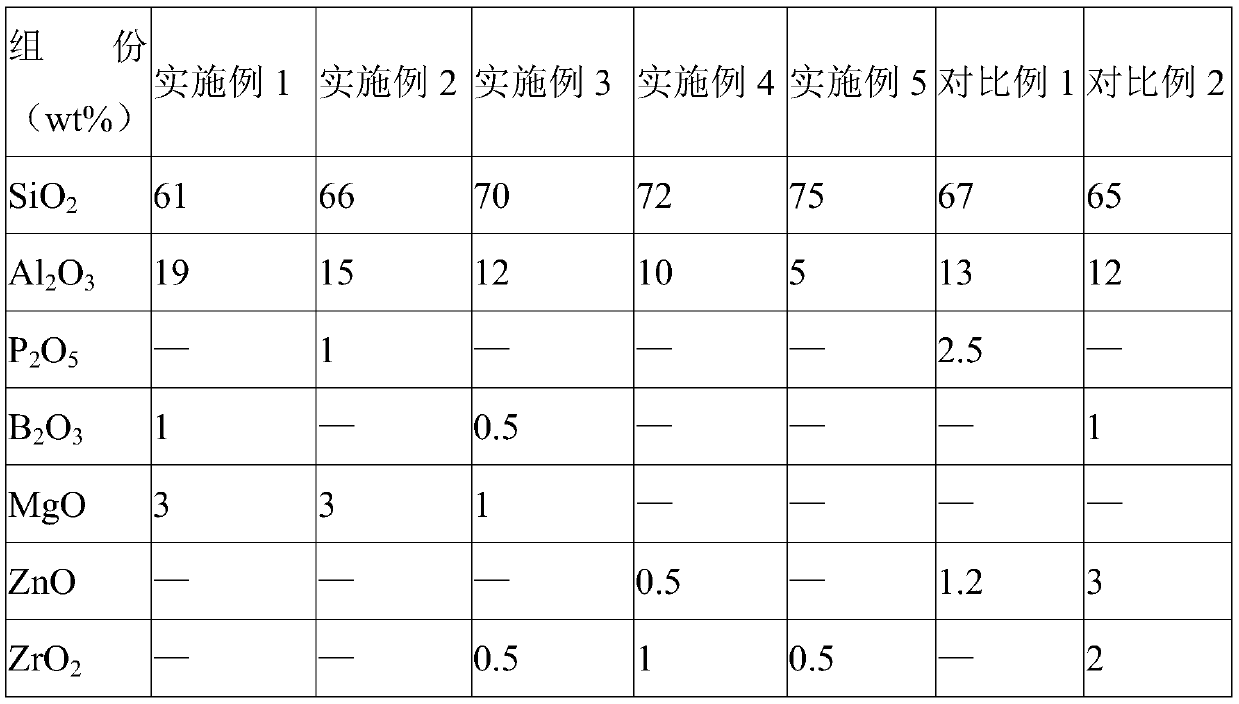

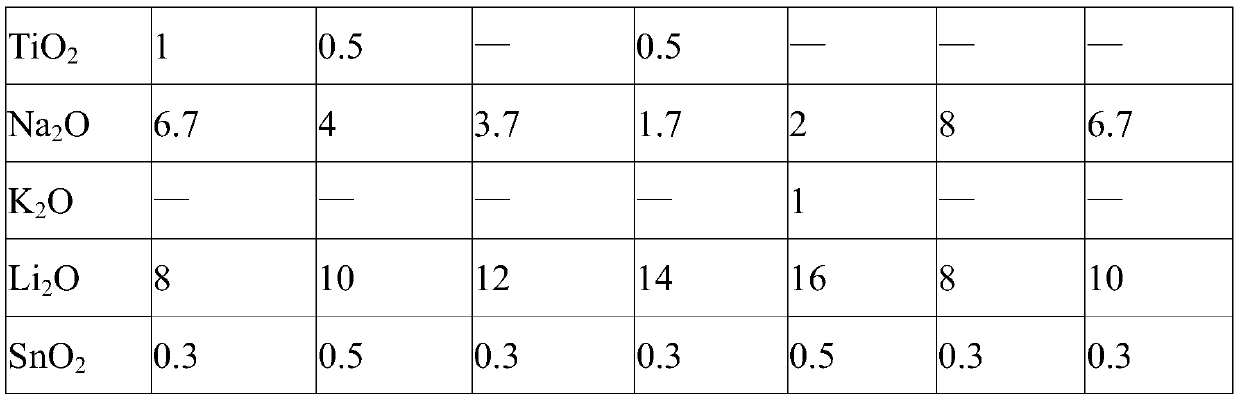

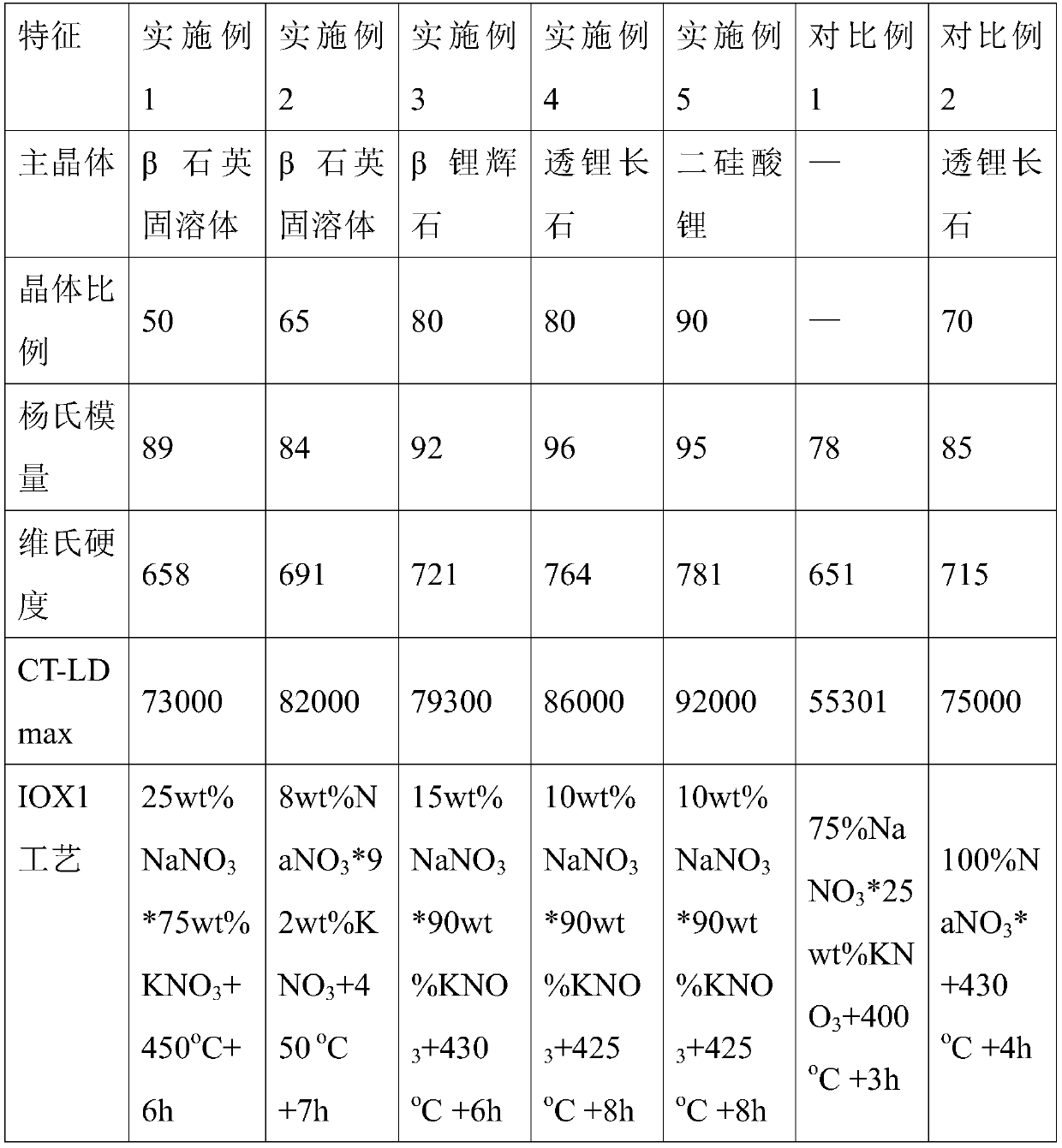

[0074] The preparation method is the same as in Example 1, and the recipes and test parameters are shown in Table 1 and Table 2.

[0075] Combining Table 1 and Table 2, the depth of the compressive stress layer of the strengthened glass-ceramics of Examples 1-5 of the present invention accounts for more than 20% of the total thickness of the glass, the CT-LD is more than 50000Mpa / mm, and the drop resistance height exceeds 1.7m. The strength of the glass-ceramics is improved through the above-mentioned ion exchange process, and the participation of lithium ions in the ion-exchange can make the high-pressure stress and stress relaxation resistance of the glass-ceramics resist the weakening effect of the lithium-containing salt bath on the deep compressive stress. It has high crystallinity, which improves the intrinsic network structure strength of glass-ceramics, which can accommodate high compressive stress and less stress relaxation at high temperature; the first step is to str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com