Carbon nanotube composite cobalt sulfide nanomaterial and preparation method and application thereof

A carbon nanotube composite and nanomaterial technology, which is applied in the field of carbon nanotube composite cobalt sulfide nanomaterials and its preparation, can solve the problems of cycle performance degradation and achieve the effects of smaller expansion range, improved pore size distribution, and inhibition of expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

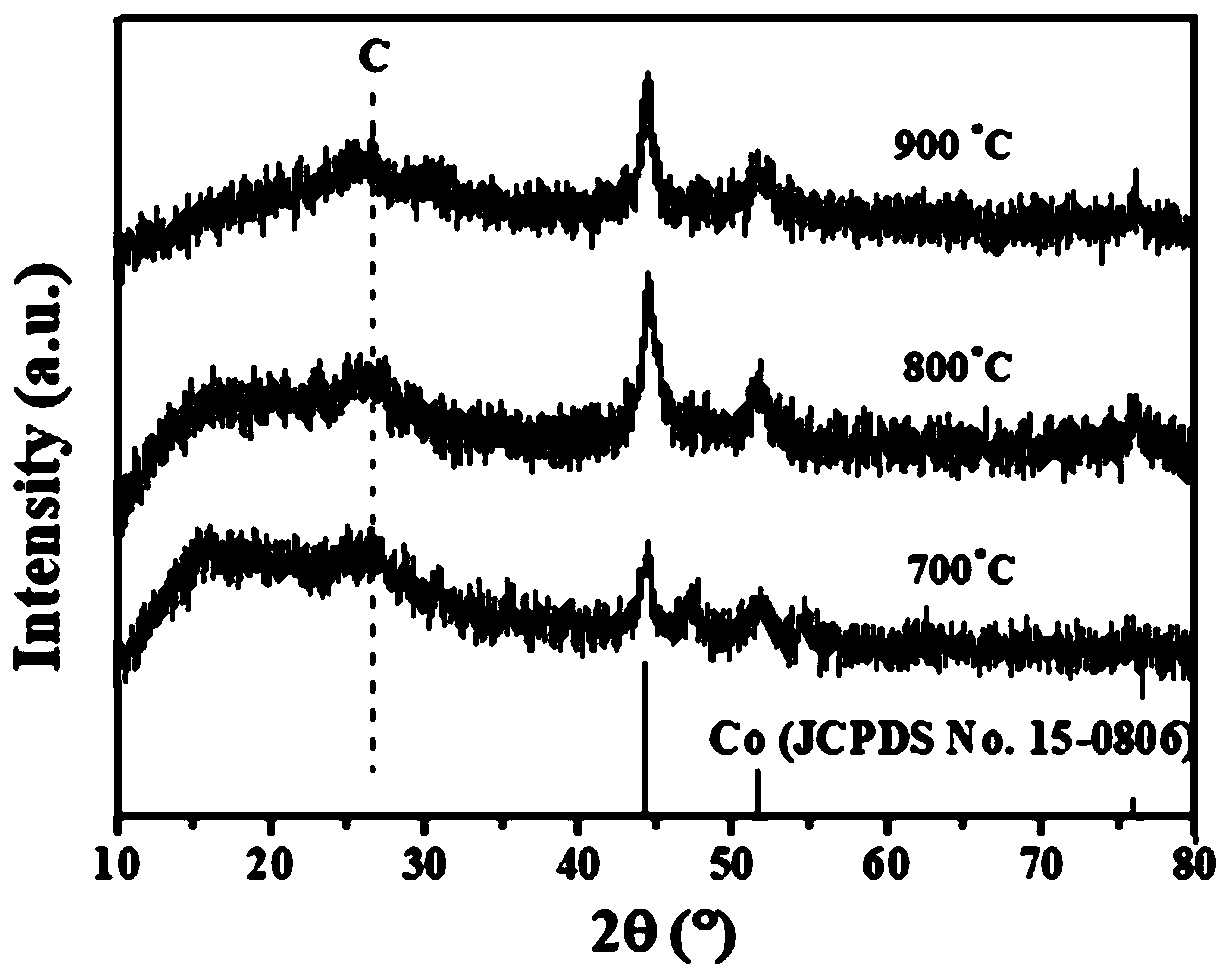

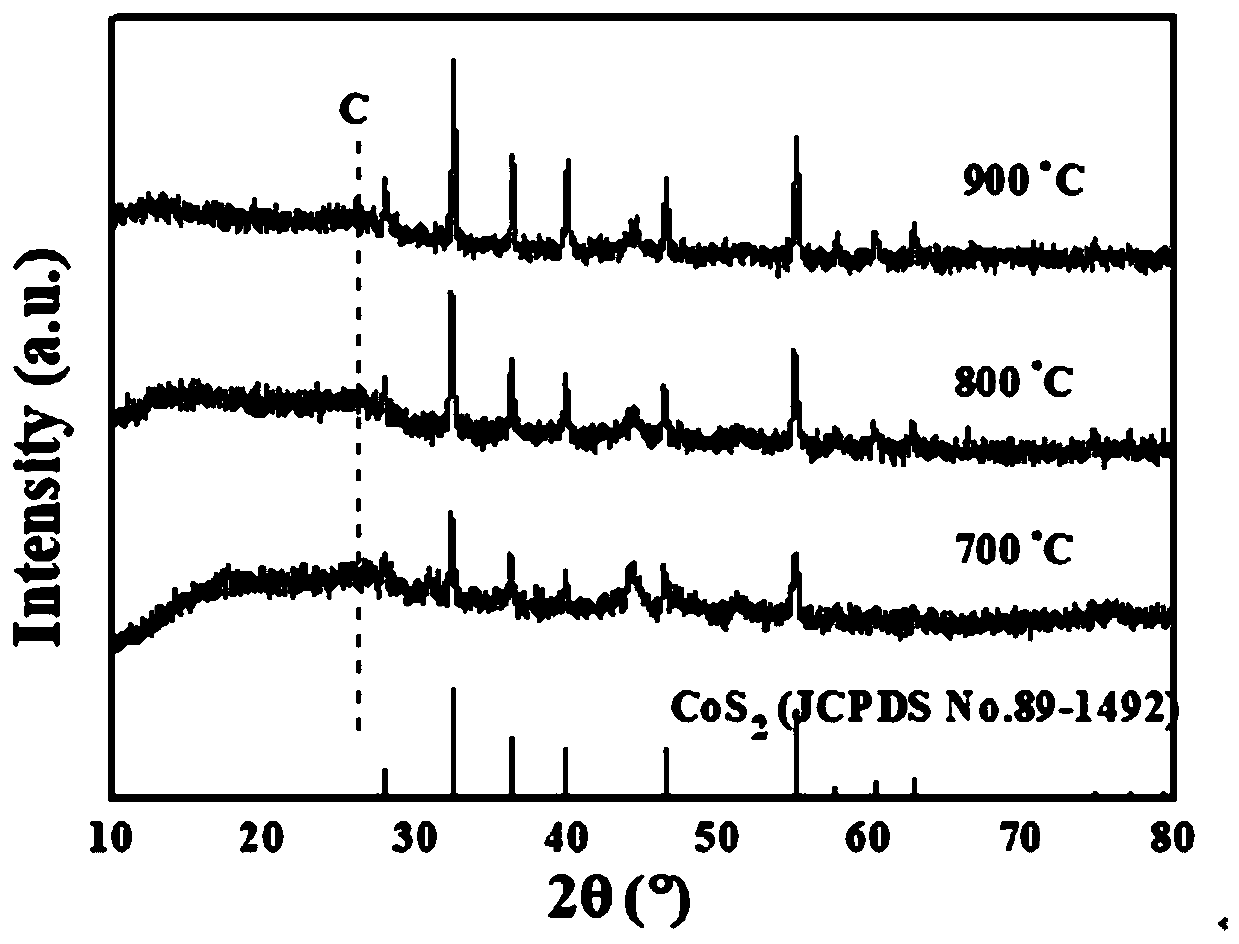

[0031] This embodiment provides a carbon nanotube composite cobalt sulfide nanomaterial, the preparation method of which comprises the following steps:

[0032] (1) 1.0g Co(NO 3 ) 2 ·6H 2 O and 1.0g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 15ml methanol solution respectively to obtain 0.2mol / L Co(NO 3 ) 2 solution and Zn(NO 3 ) 2 solution, in addition, 1.2 g of 2-methylimidazole was fully dissolved in 30 ml of methanol solution to obtain a 0.5 mol / L 2-methylimidazole solution.

[0033] Will Co(NO 3 ) 2 The solution was slowly added dropwise to the 2-methylimidazole solution, and then the mixed solution was slowly added dropwise to the Zn(NO 3 ) 2 In the solution, it was stirred for 30 min and left for 24 h to form a precipitate. Collect the precipitate and disperse it in methanol solution for several times of centrifugation, finally wash with deionized water at least 3 times, and dry at 80-120°C for 12-24 hours to obtain a blue powder, which is the zeolite imidazolate...

Embodiment 2

[0042] The present invention also provides an electrode, which is made of the carbon nanotube composite cobalt sulfide nanomaterial prepared in Example 1 as an active material, and simultaneously includes a conductive agent and a binder, wherein the conductive agent can be selected from acetylene black and the binder Select polytetrafluoroethylene (PTFE) or polyvinylidene fluoride (PVDF), and its preparation method is:

[0043] Mix carbon nanotube composite cobalt sulfide nanomaterials, acetylene black conductive agent and polytetrafluoroethylene binder (or polyvinylidene fluoride binder) according to the mass ratio of 7:2:1, add an appropriate amount of ethanol aqueous solution or N -Methylpyrrolidone solvent, ultrasonic vibration or mechanical stirring to form a uniform paste.

[0044] The paste was air-dried at 100°C for 12 hours, then taken out, rolled into a sheet and placed on foamed nickel, and pressed into a sheet to obtain the electrode. Alternatively, the paste was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com