Full-automatic unmanned operation management system for crown block

A technology of operation management and management system, which is applied in the field of crane automatic unmanned operation management system, can solve the problems that the crane is easy to collide with the end beam, the work is tedious, and mistakes are easy to make, so as to improve the transmission efficiency, optimize the personnel structure, Effects of preventing product damage and equipment accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

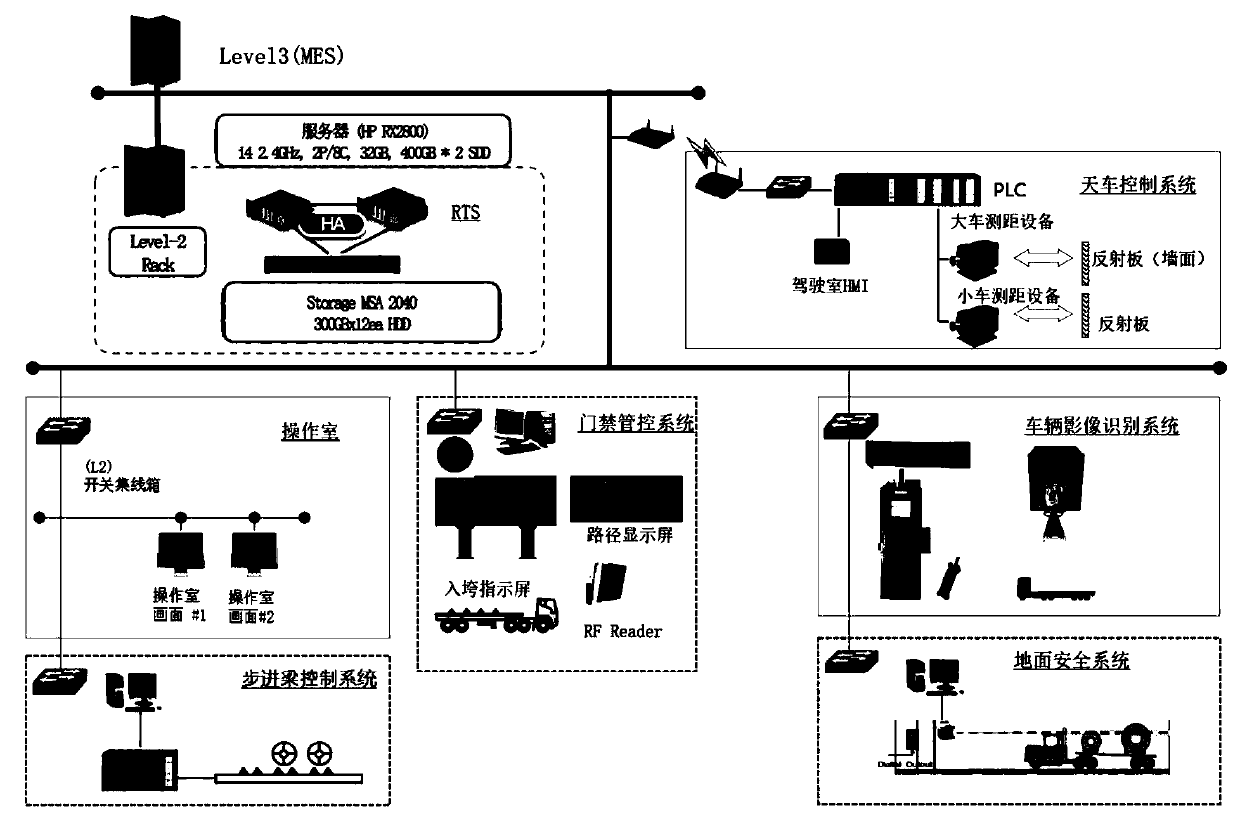

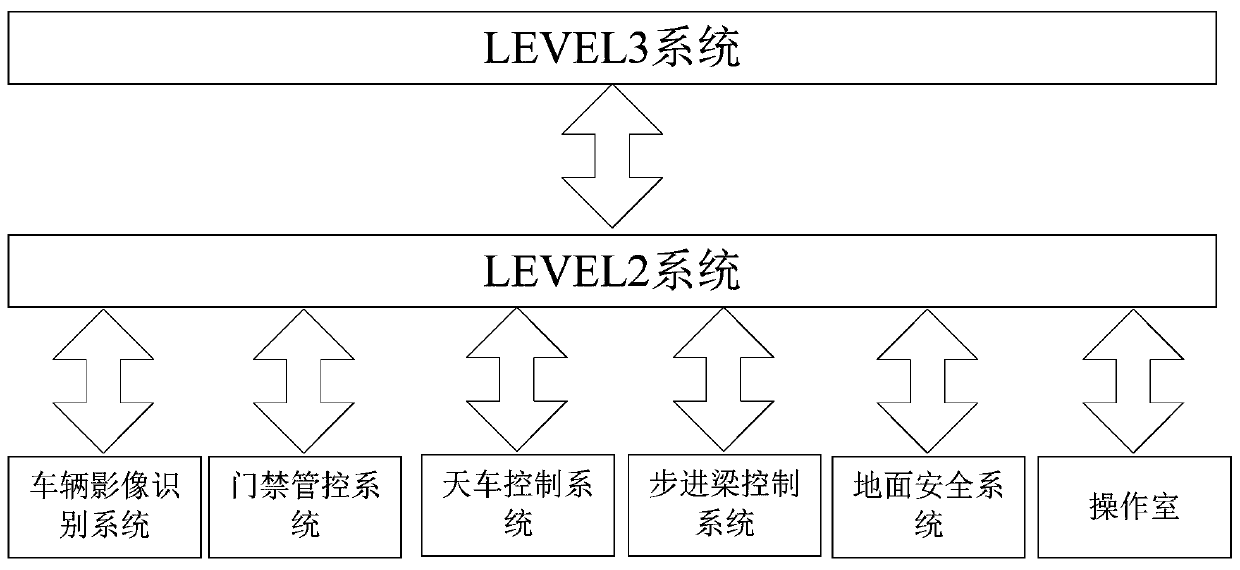

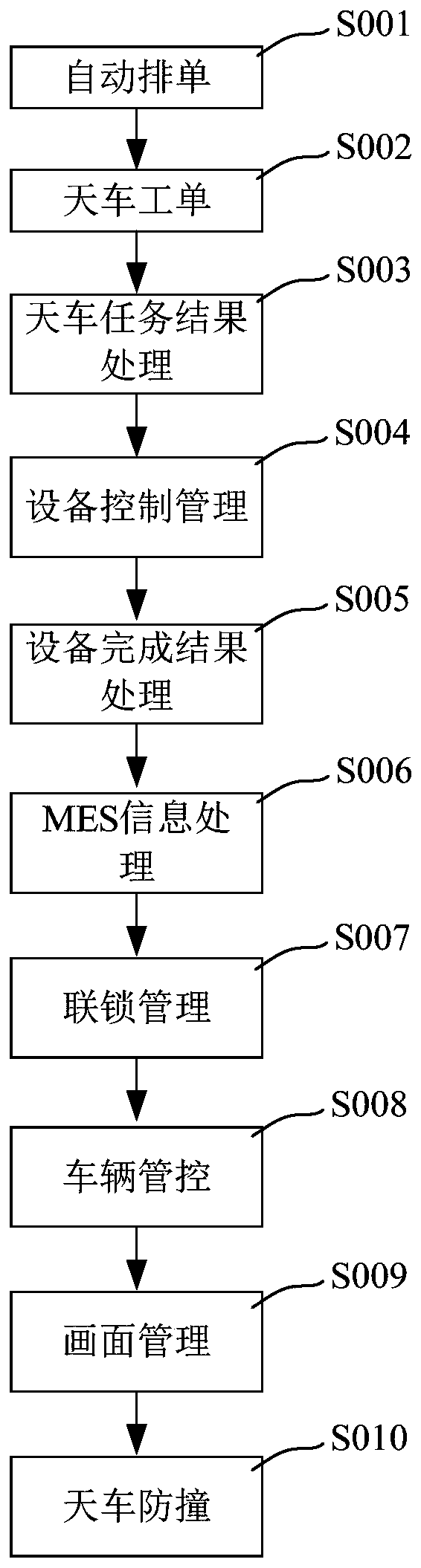

[0038] Such as figure 1 As shown, the present invention provides a technical solution: a crane automatic unmanned operation management system includes Level3 system, Level2 system, vehicle image recognition system, access control management system, crane control system, ground safety system, operating room and Walking beam control system; the Level3 system is connected to the Level2 system through wires, and the Level2 system is wirelessly connected through a router; the Level2 system is connected to the vehicle image recognition system, the access control management system and the operating room through data lines; The above operating room is connected to the access control management system through a data line; the vehicle image recognition system is connected to the ground security system through a data line.

[0039] The crane control system includes PLC, cab HMI, cart distance measuring equipment, trolley distance measuring equipment and reflector; the PLC and cab HMI are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com