Single-cylinder driven dual-pressing-head reinforced clamp self-locking, removal and jacking mechanism

A technology of jacking mechanism and double pressure head, which is applied in the direction of auxiliary equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., and can solve the problem of reducing the reliability of the design space positioning of the tightening mechanism and the strength level, increasing the positioner, welding In order to avoid problems such as severe deformation, it can achieve the effect of increasing the range of use, saving the space occupied by the mechanism, and ensuring the welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

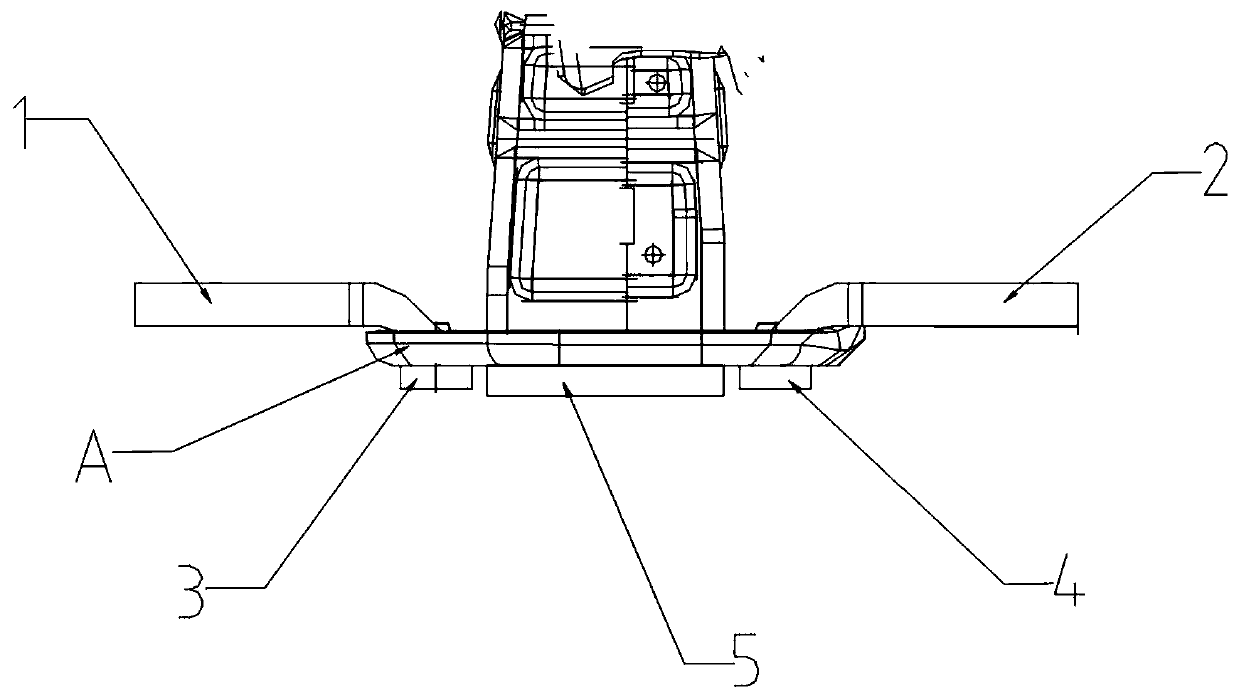

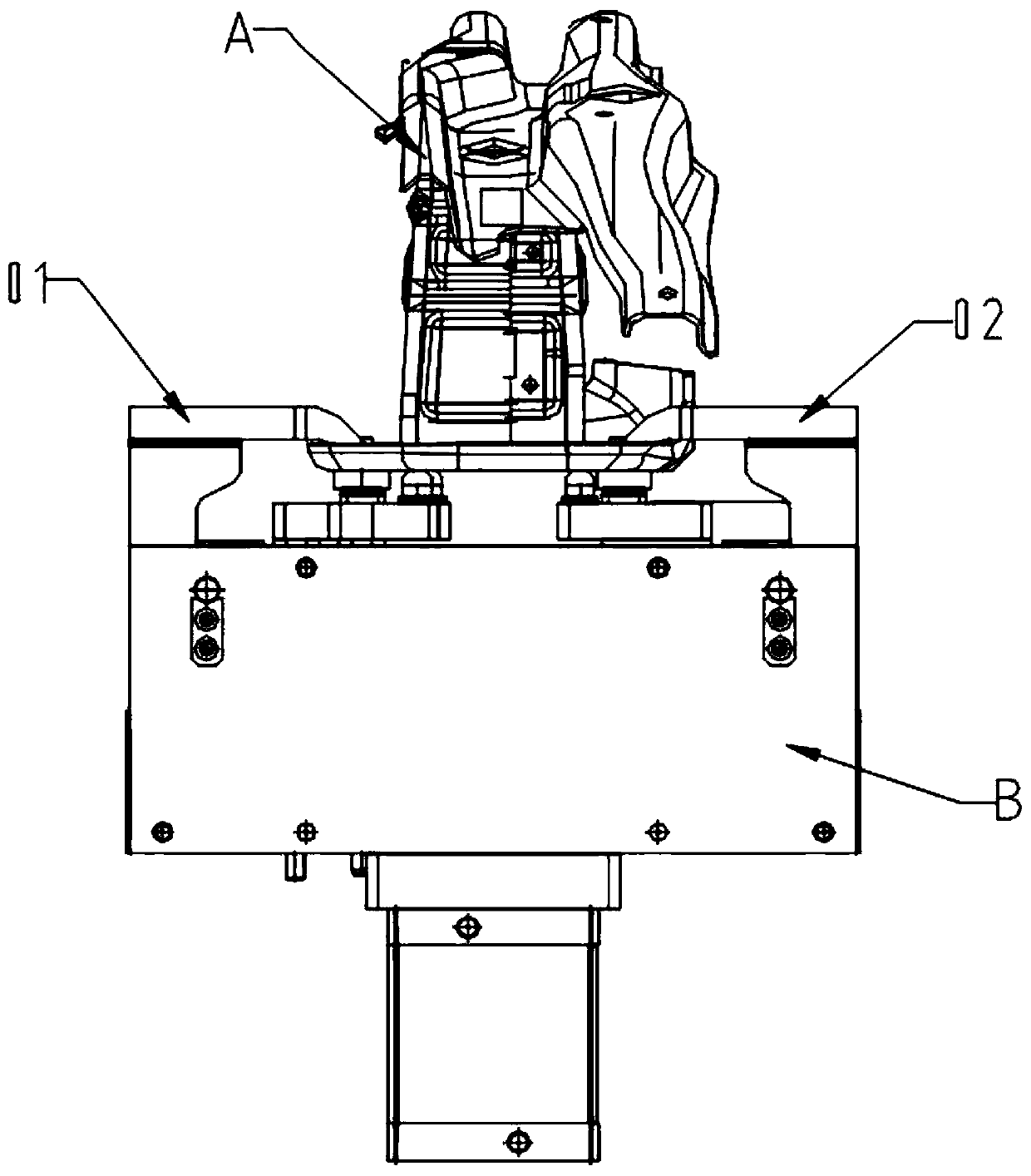

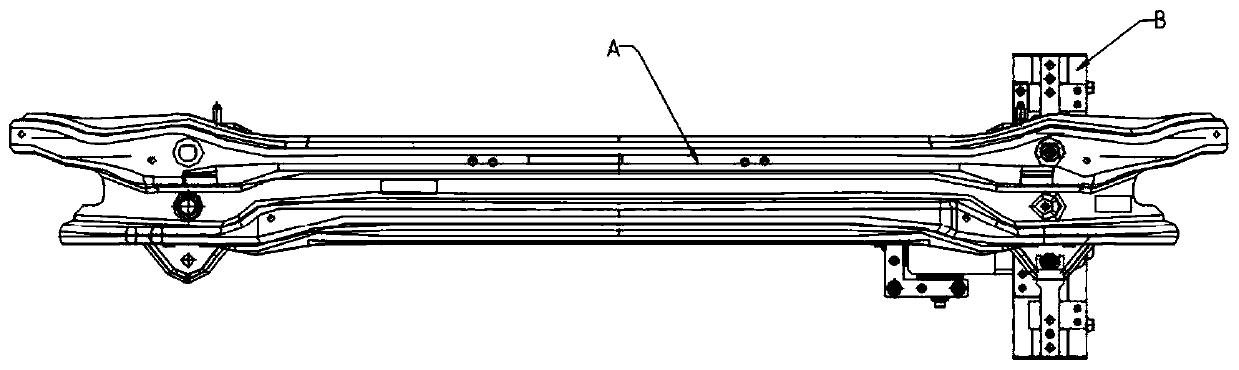

[0028] Example: such as Figure 1-8 As shown, a single-cylinder-driven double-indenter force-increasing clamping and self-locking mechanism simultaneously opens the belt jacking mechanism, which includes a rotating shaft 29, a pressing arm 4, a pressing arm 5, a connecting plate 19, and a connecting plate 20. The plate two 20 is located on one side of the whole device. One end of the connecting plate two 20 is provided with a pressing arm 4, and the connecting plate 20 is provided with a pressing arm 5 at the other end on the same side as the pressing arm 4. One end of arm two 5 in the direction of non-connecting plate two 20 is provided with a connecting plate 19, connecting plate one 19, connecting plate two 20, and pressing arm two 5 are connected together through rotating shaft two 29, connecting plate one 19, connecting plate two 20, The pressing arm 4 is penetrated and connected by the second rotating shaft 29, and the connecting plate 19 and the connecting plate 20 are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com