Corn straw crusher

A technology of corn stalks and pulverizers, which is applied in the field of agricultural machinery, can solve the problems that the stirring mechanism cannot carry out effective stirring and complex structure, and achieve the effect of reducing invalid cutting rate, reducing sliding friction, and facilitating smooth flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The standard parts used in the present invention can be purchased from the market, and the special-shaped parts can be customized according to the instructions and the accompanying drawings. The specific connection methods of each part adopt mature bolts, rivets, welding in the prior art , pasting and other conventional means, no longer described in detail here.

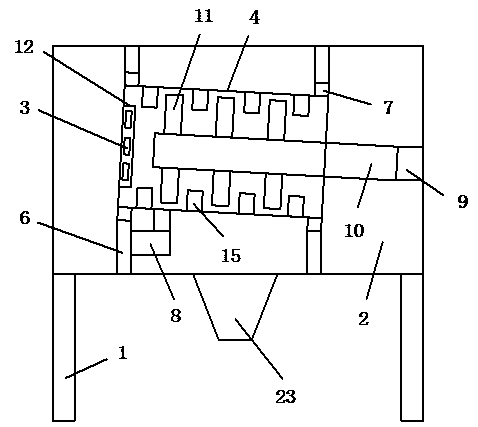

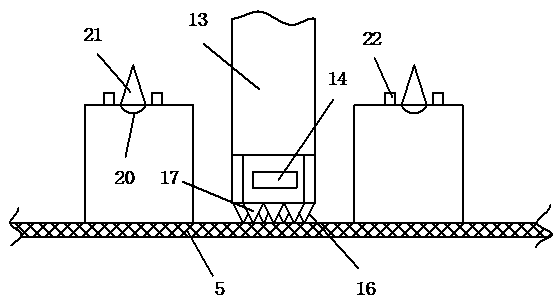

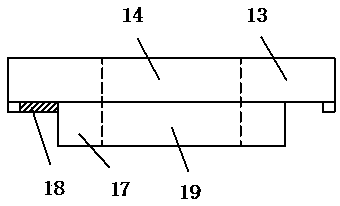

[0017] refer to Figure 1-3 , the specific embodiment includes a frame 1, a material holding box 2 is fixed on the frame 1, a crushing mechanism is fixed in the material holding box 2, and the crushing mechanism includes an outer cylinder 4, and one end of the outer cylinder 4 is provided with a feeding port 12. The side wall of the outer cylinder 4 is provided with a filter screen 5, and a bracket 6 is fixed inside the storage box 2, and the bracket 6 is movably connected with the outer cylinder 4 through a bearing 7, and the first bracket connected with the outer cylinder 4 is installed on the bracket 6. Dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com