Method for analyzing sensitivity of geometric errors of dual-rotation axes of five-axis CNC machine tool

A sensitivity analysis, dual-rotation axis technology, applied in program control, computer control, general control system, etc., can solve the problem of rapid identification of geometric errors of dual-rotation axes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

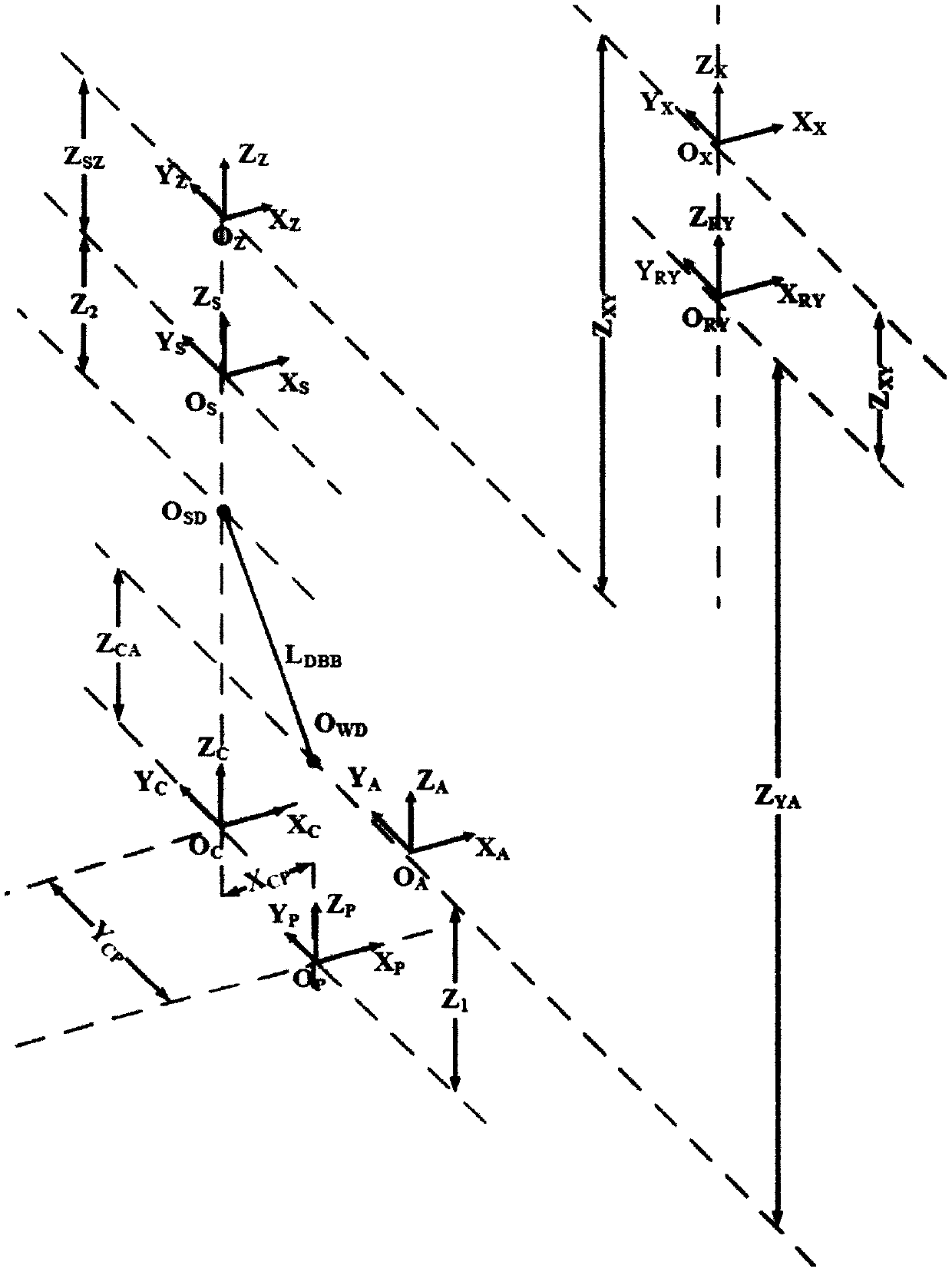

[0074] In order to solve the above-mentioned problems, the present invention proposes a method for identifying the geometric errors of the dual rotation axes of a five-axis CNC machine tool based on sensitivity analysis. Errors were subjected to Sobol sensitivity analysis. The invention can easily and accurately identify geometric errors, obtain the degree of influence of each error element on the total error, and then improve processing quality by controlling key geometric errors. Specific steps are as follows:

[0075] Step 1. Using multi-body system theory and homogeneous transformation matrix to model geometric errors, the specific steps are as follows:

[0076] Step 1.1. Set the reference coordinate system and the local coordinate system for the CNC machine tool based on the topological structure relationship of the CNC machine tool components, and set the Y-axis local coordinate system to coincide with the reference coordinate system. The reference coordinate system of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com