High-temperature smoke generator and control method thereof

A high-temperature flue gas and generator technology, applied in combustion methods, combustion chambers, combustion equipment, etc., can solve problems such as harming human health and reducing combustion efficiency, reducing emissions, reducing oxygen concentration and peak flame temperature, reducing Effects of blend inhomogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

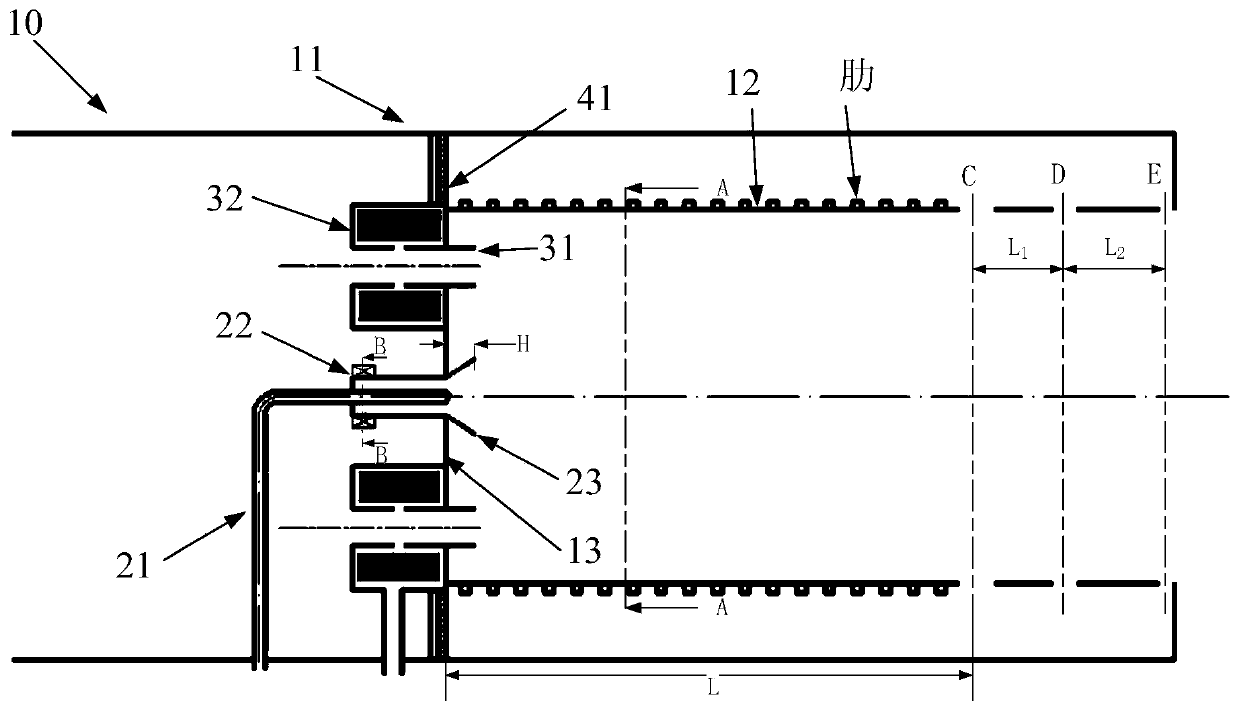

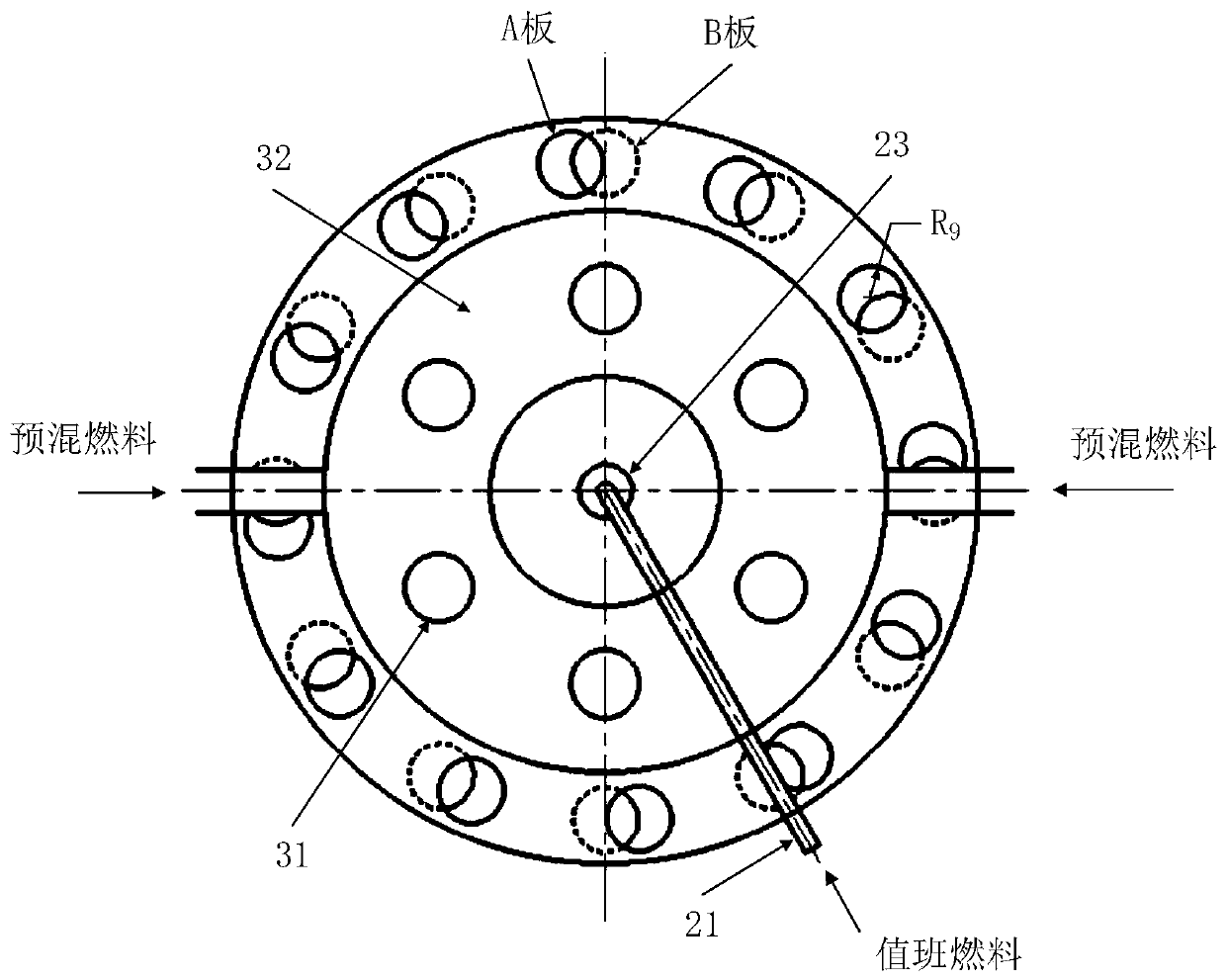

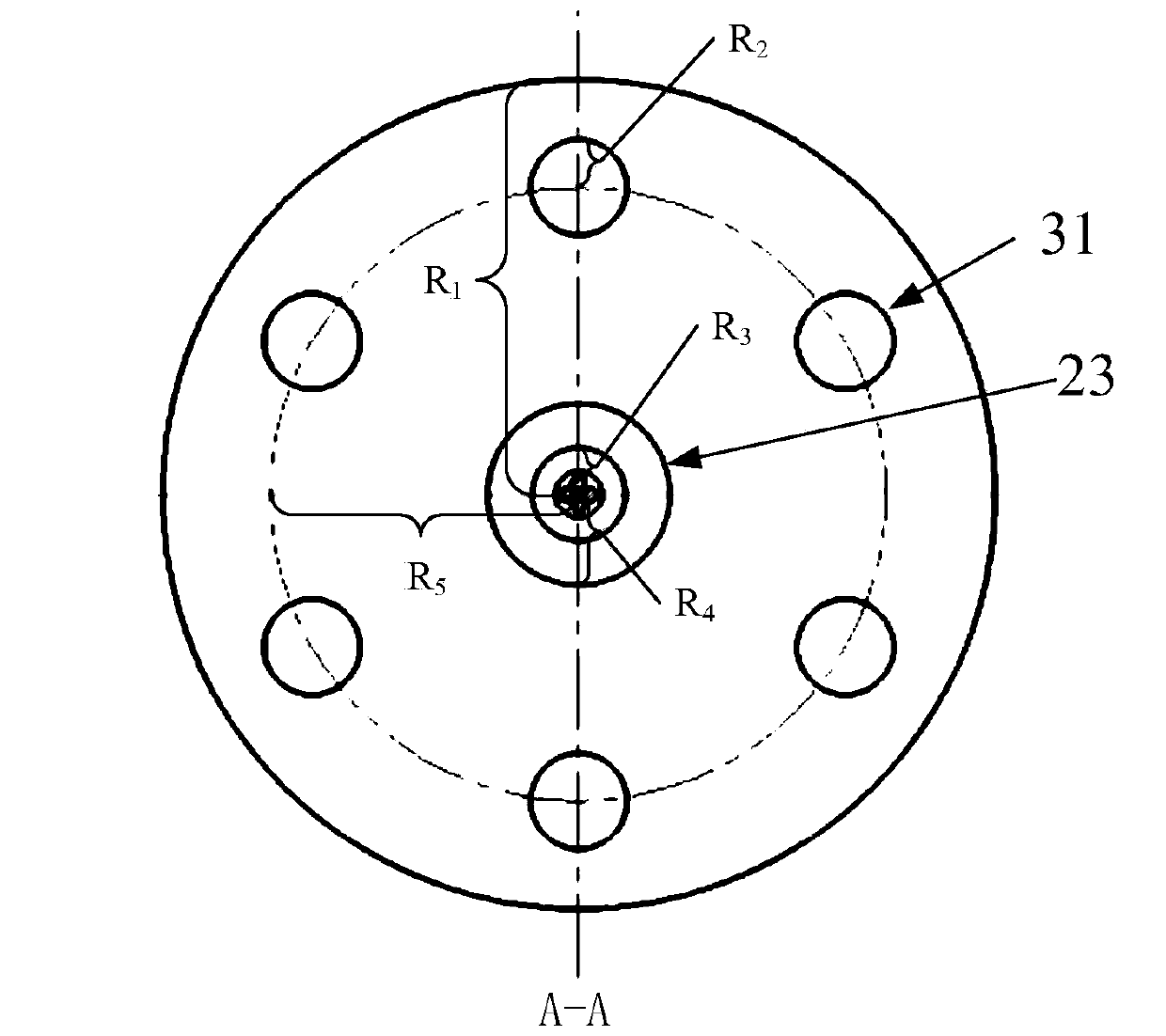

[0067] The invention provides a high-temperature flue gas generator and its control method. By arranging a duty nozzle assembly and a premixing nozzle assembly at the head of the combustion chamber, the premixing nozzle assembly injects high-speed premixed combustible gas into the combustion chamber. The high-speed entrainment and backflow of the mixed gas forms a stable flue gas recirculation zone inside the combustion chamber, which makes the premixed gas and flue gas more strongly mixed during the combustion process, thereby reducing the oxygen concentration in the combustion zone and further inhibiting The formation of a local high temperature zone is achieved, thereby achieving ultra-low nitrogen oxide emissions. At the same time, by setting the air flow distribution regulating valve, the downstream of the flame tube cooperates with the use of the air flow distribution regulating valve, which facilitates the adjustment of the outlet temperature of the flue gas generator, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com