Polypropylene/polyamide/polyketone composite material and preparation method thereof

A composite material and polyamide technology, applied in the field of materials, can solve the problems of inability to obtain color and high metal texture, poor scratch resistance of resin matrix, and easy scratches of spray-free materials, etc., to achieve excellent mechanical properties and Scratch resistance, high metallic feel and gloss, high metallic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

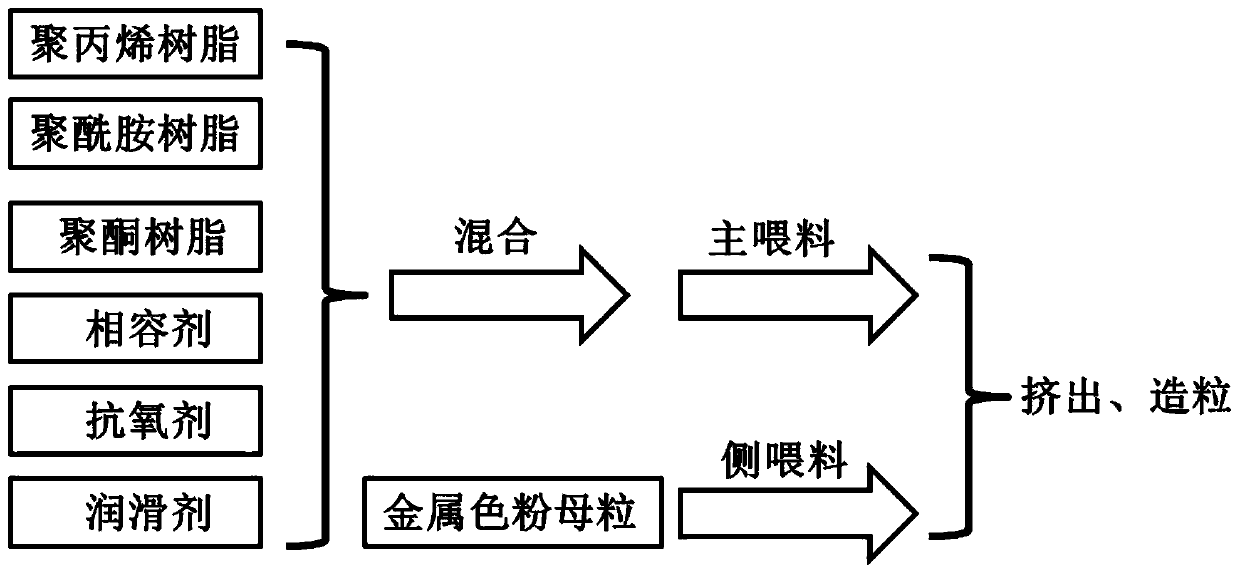

Method used

Image

Examples

Embodiment 1

[0069] A polypropylene / polyamide / polyketone composite material is prepared from the following raw materials in parts by weight:

[0070]

[0071] Antioxidant: 0.5 parts of β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate;

[0072] 0.5 part of lubricant calcium stearate;

[0073] Metal toner masterbatch 3 parts.

[0074] Wherein, the preparation method of metallic color powder masterbatch is as follows:

[0075] 1) Mix the metallic toner aluminum powder and polyacrylic acid with a weight average molecular weight of 10000 in a mass ratio of 1:10 with a mixer, the speed of the mixer is 100r / min, and the mixing time is 1min;

[0076] 2) Adding polypropylene powder with an average particle size of 0.01mm to the mixture obtained in step 1), the mass ratio is 1:1 according to the total mass of the mixture obtained in step 1) and the quality of polypropylene powder, Continue to mix with a mixer, the rotating speed of the mixer is 100r / min, and the mixing time is 1min...

Embodiment 2

[0083] A polypropylene / polyamide / polyketone composite material is prepared from the following raw materials in parts by weight:

[0084]

[0085]

[0086] Wherein, the preparation method of metallic color powder masterbatch is as follows:

[0087] 1) Mix metallic toner silver powder and polyacrylic acid with a weight-average molecular weight of 30,000 in a mass ratio of 1:5 with a stirrer, the speed of the stirrer is 200r / min, and the mixing time is 2min;

[0088] 2) Adding polypropylene powder with an average particle size of 10mm to the mixture obtained in step 1), the mass ratio is 1:1 according to the total mass of the mixture obtained in step 1) and the quality of polypropylene powder, and then Continue to mix with a mixer, the speed of the mixer is 200r / min, and the mixing time is 2min;

[0089] 3) Add the mixed material in step 2) into the parallel twin-screw extruder through the side feeder, then melt and extrude, and granulate to obtain the metallic color powde...

Embodiment 3

[0095] A polypropylene / polyamide / polyketone composite material is prepared from the following raw materials in parts by weight:

[0096]

[0097] Wherein, the preparation method of metallic color powder masterbatch is as follows:

[0098] 1) Mix metallic toner silver powder and polyacrylic acid with a weight-average molecular weight of 50,000 in a mass ratio of 1:5 with a stirrer, the speed of the stirrer is 200r / min, and the mixing time is 2min;

[0099] 2) Adding polypropylene powder with an average particle diameter of 1 mm to the mixture obtained in step 1), the mass ratio is 1:1 according to the total mass of the mixture obtained in step 1) and the quality of polypropylene powder, and then Continue to mix with a mixer, the speed of the mixer is 200r / min, and the mixing time is 2min;

[0100] 3) Add the mixed material in step 2) into the parallel twin-screw extruder through the side feeder, then melt and extrude, and granulate to obtain the metallic color powder master...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com