Hazardous waste sludge separation type treatment device

A treatment device and sludge treatment technology, applied in sludge treatment, water/sludge/sewage treatment, neutralized water/sewage treatment, etc., can solve the problem of automatic adjustment of mixing methods, hazardous waste combustion, damage to mixing mechanisms, etc. problem, achieve the effect of reducing the risk of combustion and explosion, reducing metal ions, and avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

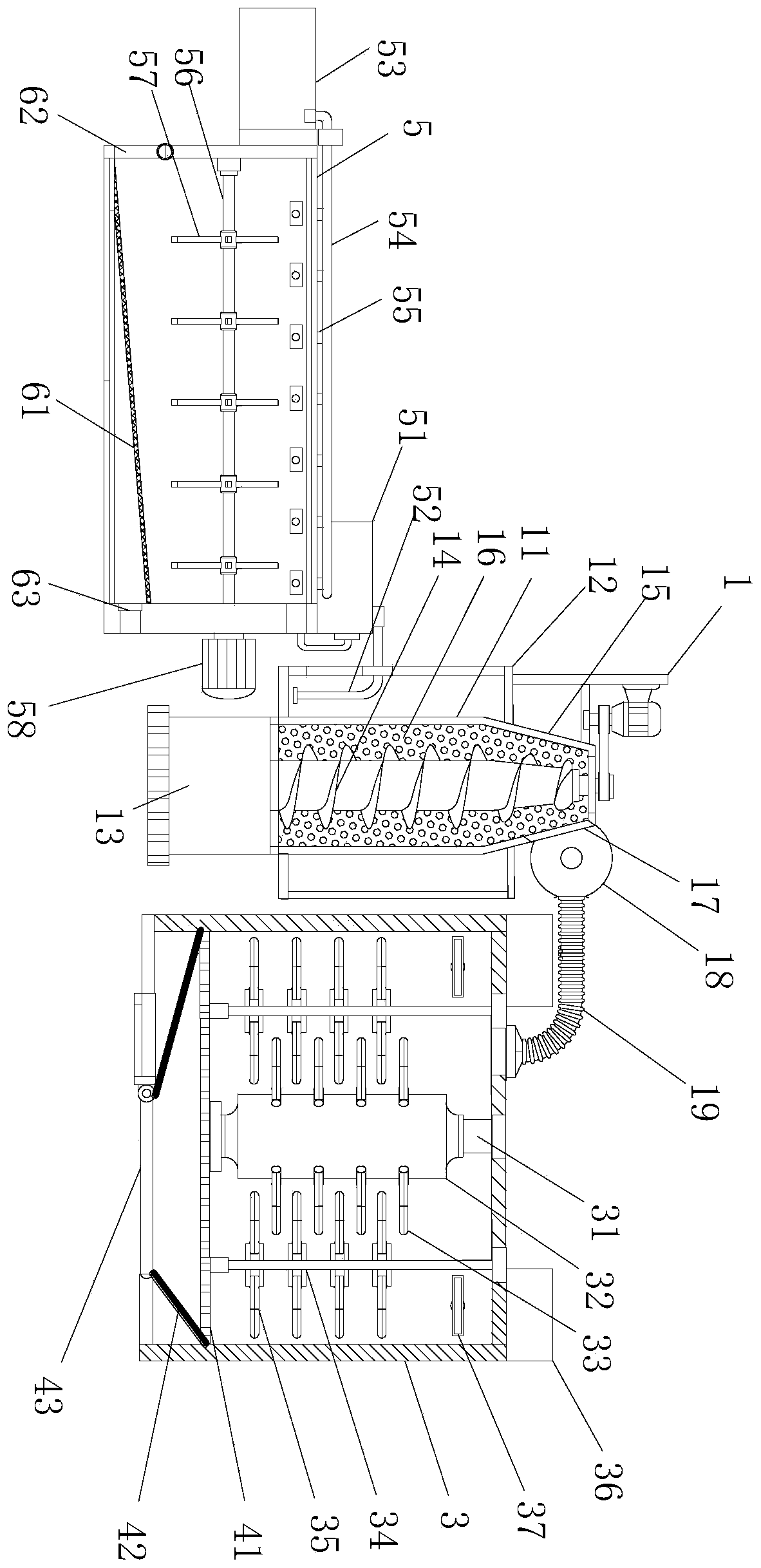

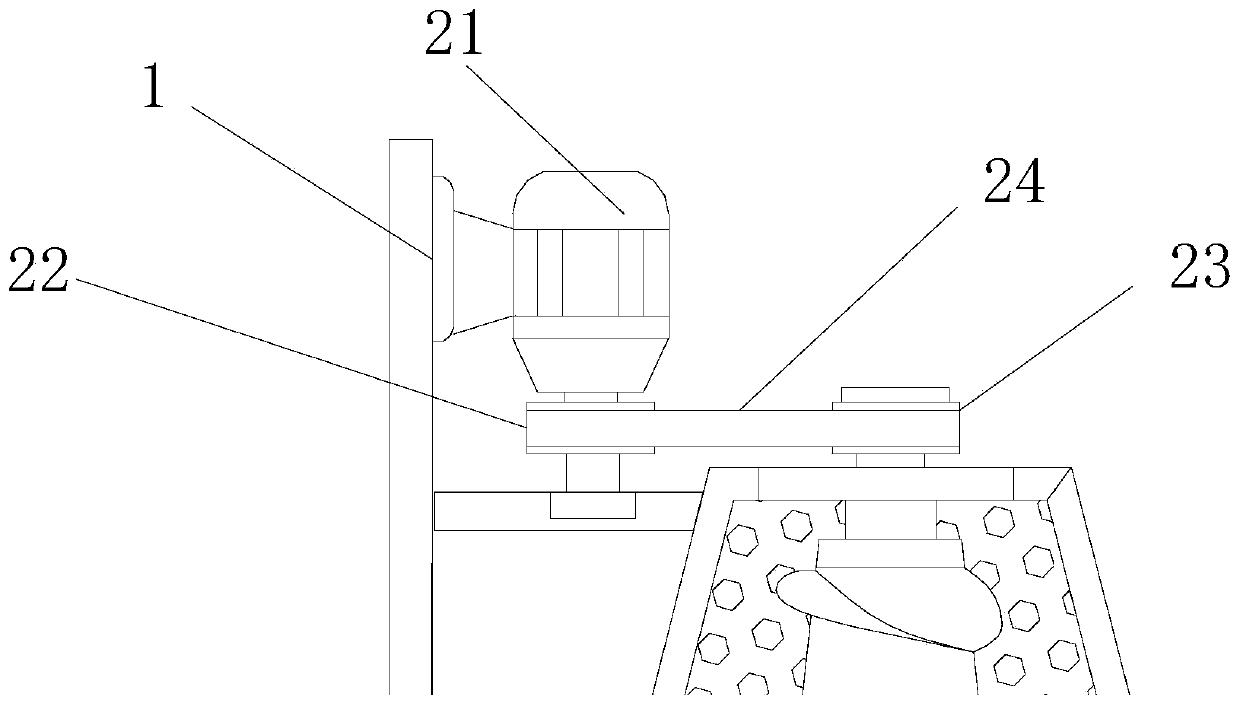

[0030] see Figure 1~3 , a hazardous waste sludge separation treatment device, comprising a sludge feeder 1, a sludge treatment tank 3 and a sewage treatment tank 5, the sludge feeder 1 is provided with a feeder 11 and a water tank 12. The water storage tank 12 is wrapped and installed on the outer layer of the feeding tube 11, the bottom end of the feeding tube 11 is installed with a dredge pump joint 13, and the outer wall of the feeding tube 11 is provided with several water outlet holes 16. The auger 14 is installed inside the feeding tube 11, and the top of the feeding tube 11 is provided with a discharge end 15, and the discharge end 15 is provided with a conical structure, and the inner diameter of the tube wall is gradually shrinking. The top side of the discharge end 15 is provided with a discharge port 17, the discharge port 17 is equipped with a feed pump 18, and the discharge end of the feed pump 18 is connected with a sludge conduit 19, the sludge The mud conduit...

Embodiment 2

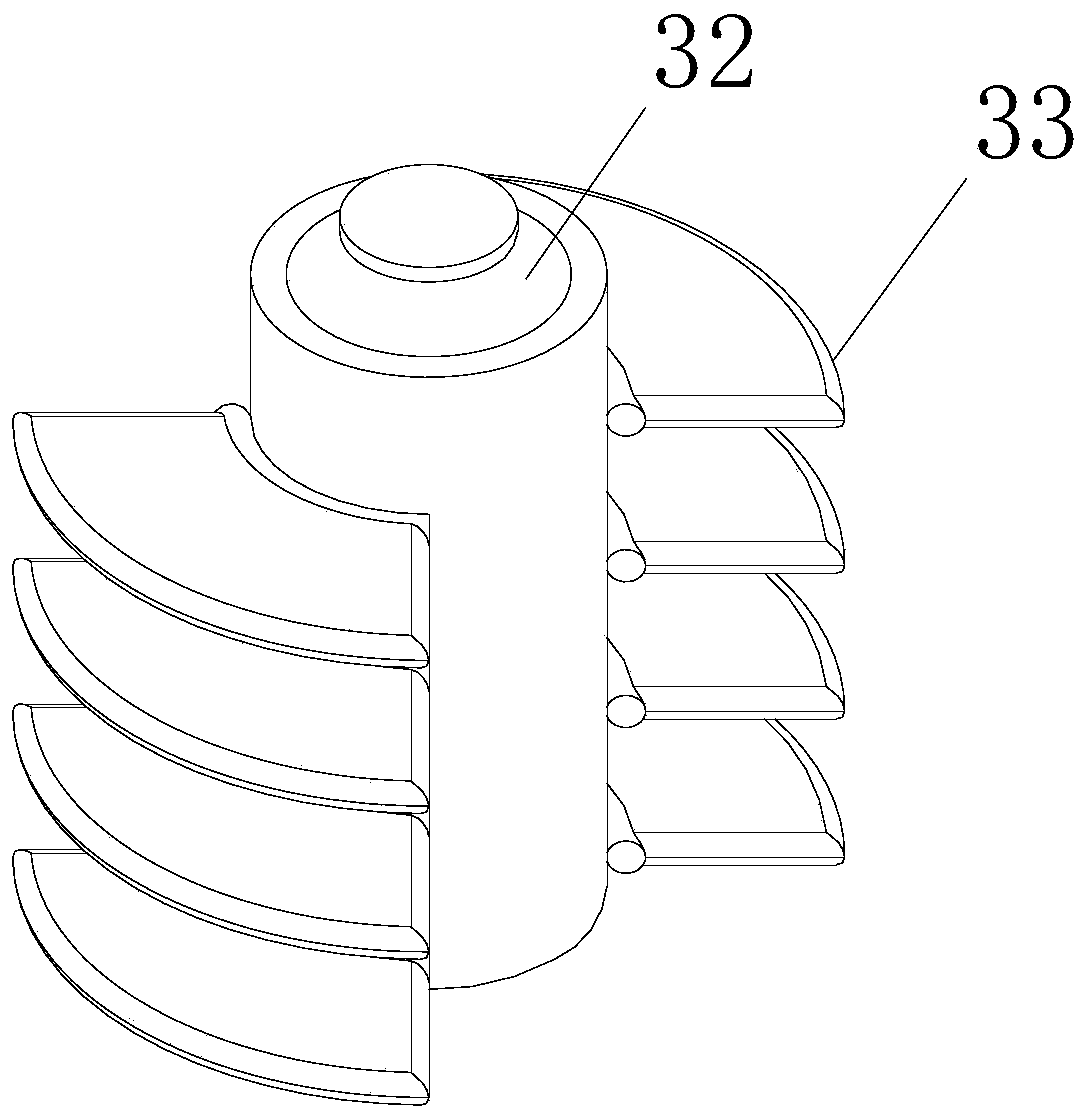

[0034] see figure 1 and image 3, this embodiment is a further optimization of Embodiment 1, on the basis of which, several sludge auxiliary material boxes 36 are arranged on the top of the sludge treatment box 3, and the feeding end of the auxiliary material box 36 extends into the sludge treatment The box 3 is also provided with a material delivery port 37. The sludge treatment box 3 is equipped with a main mandrel 31, and a driving roller 32 is installed on the main mandrel 31. Several A central shaft knife plate 33, the side of the sludge treatment box 3 is provided with several side rollers 34, and several side knife plates 35 are installed on the side roller shaft 34, and the central shaft knife plate 33 and side blade 35 are arranged in a staggered shape.

[0035] For sludge treatment operations, this application pretreats sludge by mixing auxiliary materials. The auxiliary materials mainly use potassium tripolyphosphate-based metal removal materials, hydrated zinc bo...

Embodiment 3

[0040] see figure 1 In this embodiment, as a further optimization of Embodiment 1, on the basis, a sewage auxiliary material box 53 is installed on the side of the sewage treatment tank 5, and a material delivery conduit 54 is installed at the feeding end of the sewage auxiliary material box 53, The feeding conduit 54 is connected to the sewage treatment tank 5 through several branch pipes 55. The inner cavity of the sewage treatment tank 5 is horizontally equipped with a stirring shaft 56, and several stirring rods 57 are installed on the stirring shaft 56. The sewage treatment tank 5 is externally installed with a stirring motor 58, and the stirring shaft 56 is connected with the driving end of the stirring motor 58 through a coupling.

[0041] This application uses acid-base neutralization treatment and adopts the method of stirring operation to improve the mixing of neutralizer and sewage water quality, so as to carry out acid-base pretreatment on the separated sewage, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com