An overflow prevention device and method for filling

An anti-overflow and filling technology, which is applied in the directions of packaging, packaging protection, transportation and packaging, etc., can solve the problems of rapid rising, low safety, and poor versatility of anti-overflow monitoring devices, so as to reduce the possibility of explosion and improve safety High and versatile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

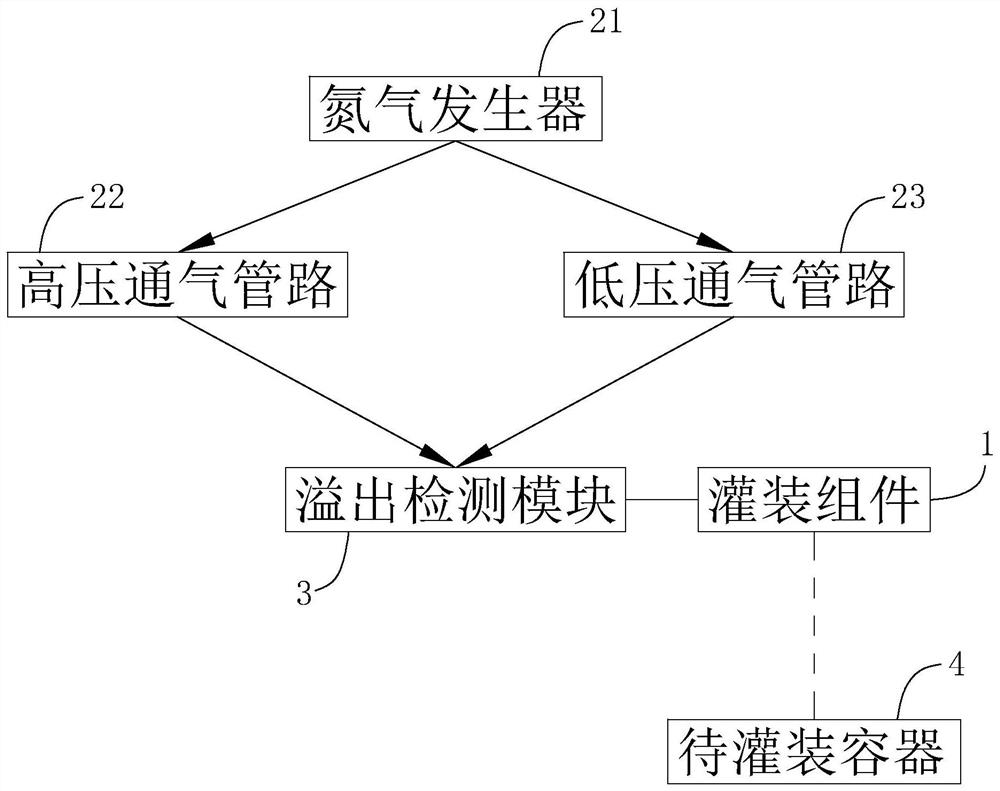

[0054] An anti-spill device for filling, such as figure 1 As shown, it is electrically connected with the filling assembly 1 , and includes a nitrogen gas supply device 2 and an overflow detection module 3 communicated with the nitrogen gas supply device 2 . The nitrogen supply device 2 includes a nitrogen generator 21 , a high-pressure ventilation pipeline 22 and a low-pressure ventilation pipeline 23 .

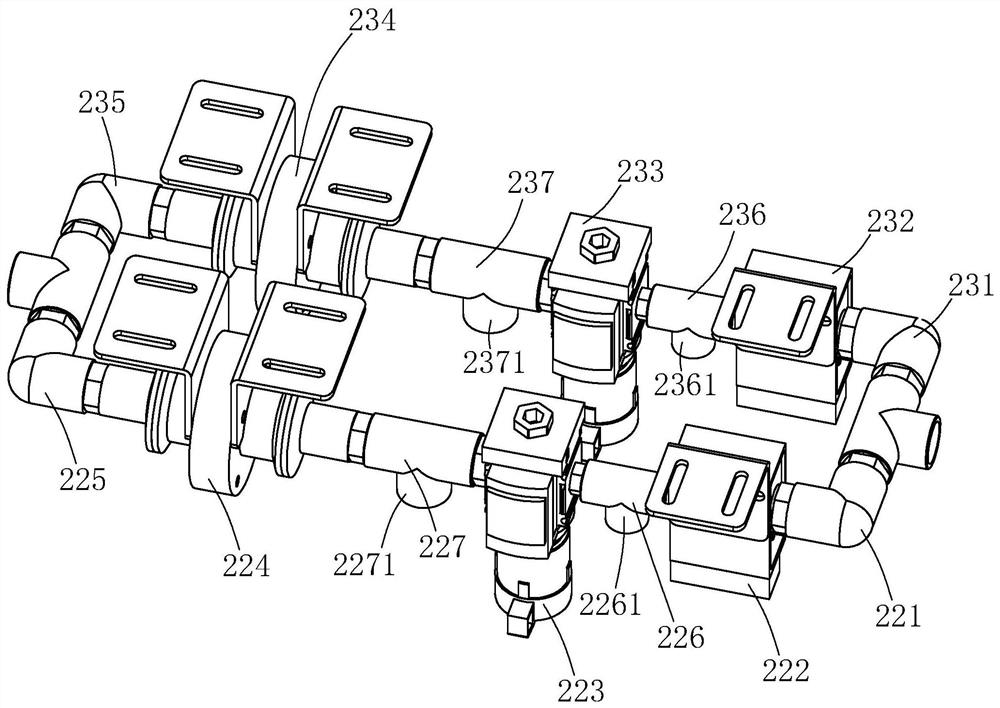

[0055] Such as figure 2As shown, the high-pressure ventilation pipeline 22 includes a first intake pipe 221, a first control valve 222, a first pressure regulating valve 223, a first butterfly valve 224, and a first outlet pipe 225 connected in sequence; the low-pressure ventilation pipeline 23 includes a sequentially connected The second air intake pipe 231 , the second control valve 232 , the second pressure regulating valve 233 , the second bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com