Grinding and polishing machine

A polishing machine and polishing disc technology, applied in grinding machine tools, grinding/polishing equipment, grinding devices, etc., can solve the problems of different fixing force, hard texture, wrinkles and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

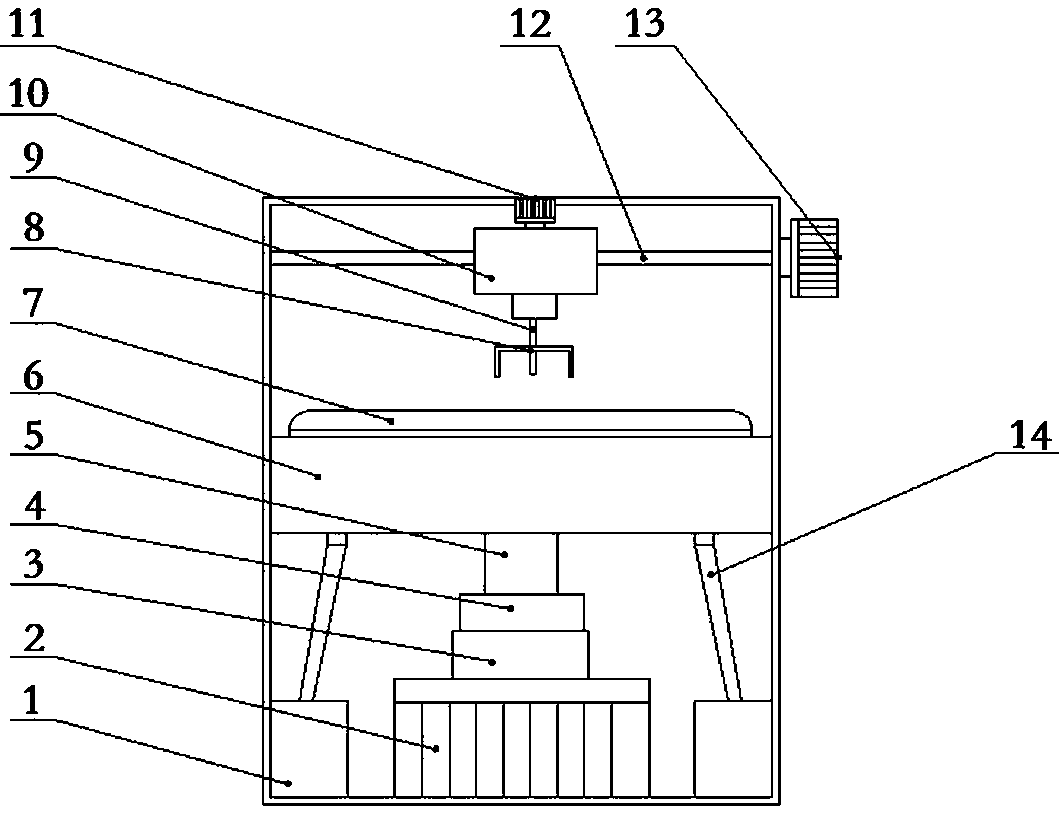

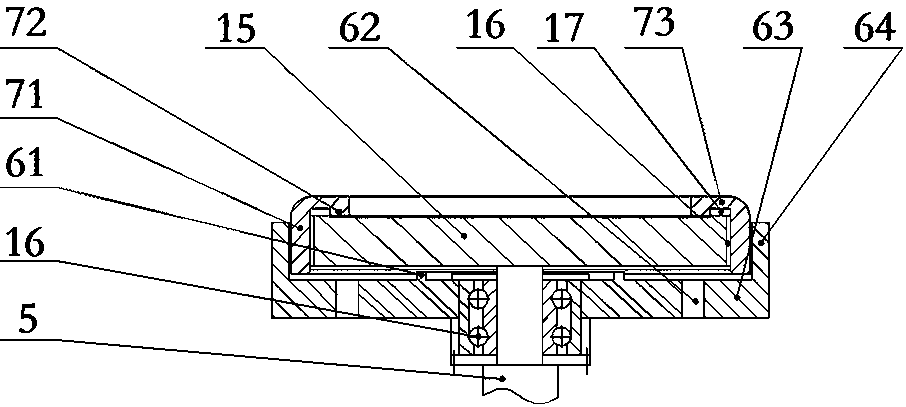

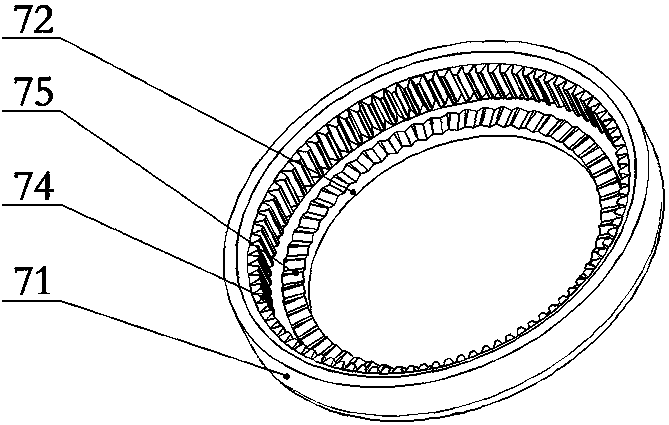

[0036] In the embodiment of the present invention, the focus is on the description of the fixing structure of the polishing cloth on the polishing disc 15 , and the other parts of the grinding and polishing machine are not described much. figure 1 It is a schematic diagram of a simplified structure of a grinding and polishing machine. Except for the fixed structure of the polishing cloth on the polishing disc 15, other parts are displayed in a simplified manner. specific structural parts.

[0037] First of all, regarding the polishing cloth, the embodiment of the present invention not only includes a special polishing cloth, but also includes such as sandpaper used for polishing. There are different options for special polishing cloths for different applications, such as LCD polishing cloths, which are made by attaching abrasives to the wear-resistant cloth base, and there are many types of abrasives, such as aluminum oxide, aluminum hydroxide, cerium oxide, diamond , silicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com