Spraying equipment

A technology of spraying equipment and spraying devices, applied in spraying devices, liquid spraying devices, etc., can solve the problems of reducing construction efficiency, inability to work in multiple directions, increasing construction complexity, etc., and achieve the effect of reducing construction complexity and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

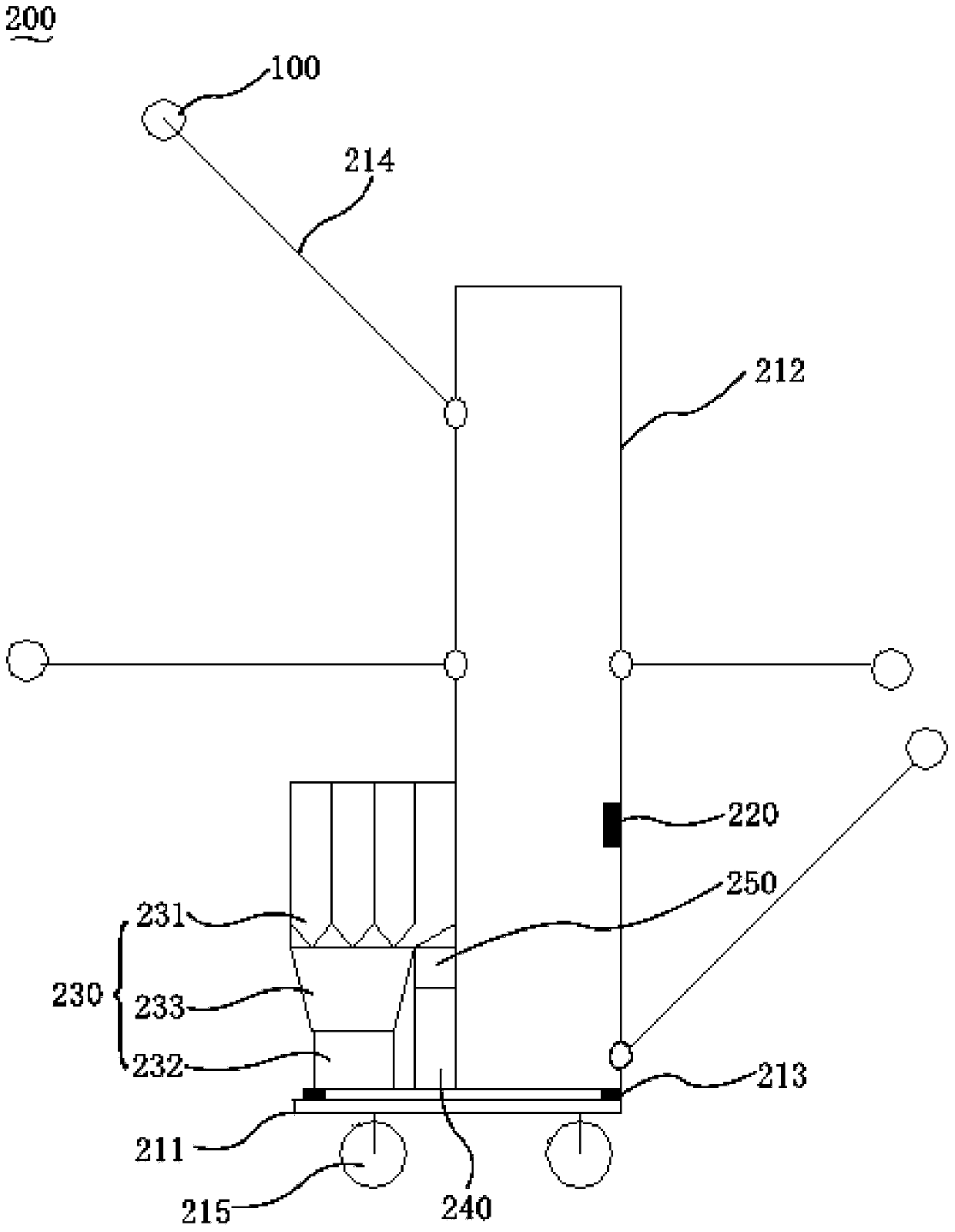

Image

Examples

preparation example Construction

[0043] In a specific example, the preparation method of the universal spraying device 100 includes the following steps S1-S5:

[0044] S1. Take a nano-alloy tube as a paint delivery tube.

[0045] S2. Take a nano-alloy plate, cut it into multiple trapezoidal alloy plates, respectively curl the multiple trapezoidal alloy plates and connect the two waists of the trapezoid to obtain multiple frustoconical rolls.

[0046] S3. Taking a plurality of nano-alloy tubes and connecting one end with a plurality of truncated cone-shaped drums respectively to obtain a plurality of nozzles.

[0047] S4. Take a multi-directional control valve, and connect multiple nozzles with multiple output ports of the multi-directional control valve.

[0048] S5. Connect one end of the paint delivery pipe to the input port of the multi-directional control valve, and the other end to the rotary joint to obtain a universal spraying device.

Embodiment 1

[0051] A nano-alloy tube with a length of 1800mm, a wall thickness of 2mm, and an inner diameter of 15mm is selected as the paint delivery tube, and both ends of the tube are treated with internal wires so as to be inserted and tightened with other components.

[0052] Select a nano-alloy plate (thickness 2mm, length 500mm, width 50mm), first use a laser cutter to continuously cut the nano-alloy plate along the long side of the plate into 4 trapezoidal alloy plates (the length of the upper base is 31.4mm, and the length of the lower base is 157mm , height 40mm), and then use laser cladding to process the remaining triangular sheet material and small trapezoidal alloy plate into a trapezoidal alloy plate with the same size as the above four trapezoidal alloy plates (to ensure that the connection is smooth and compact).

[0053] The trapezoidal alloy plate (the length of the upper base is 31.4mm, the length of the lower base is 157mm, and the height is 40mm) is rolled into a frus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com