Electrical junction box capable of preventing condensate water

An electrical junction box, condensate technology, applied in electrical components and other directions, can solve problems such as unreasonable anti-condensation structure, and achieve the effects of novel design ideas, solving electrical faults, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

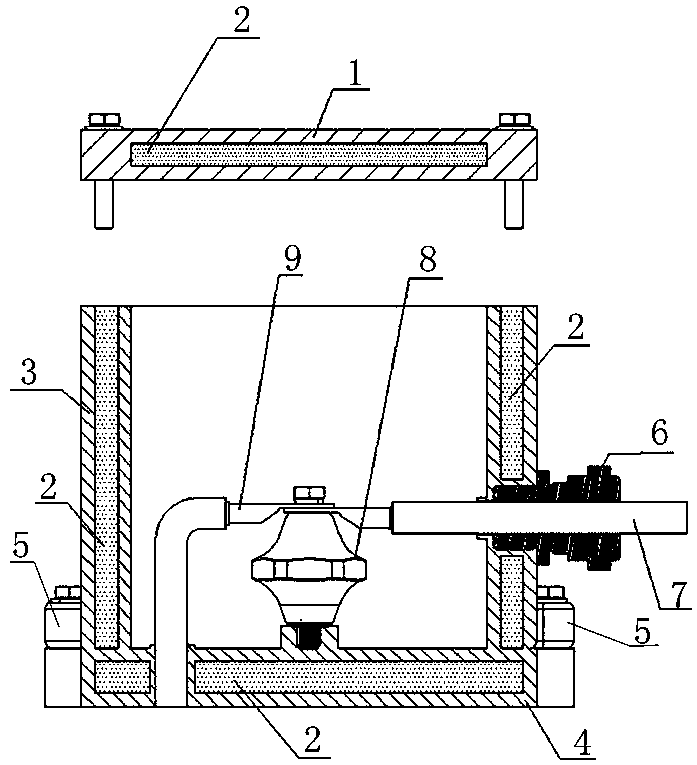

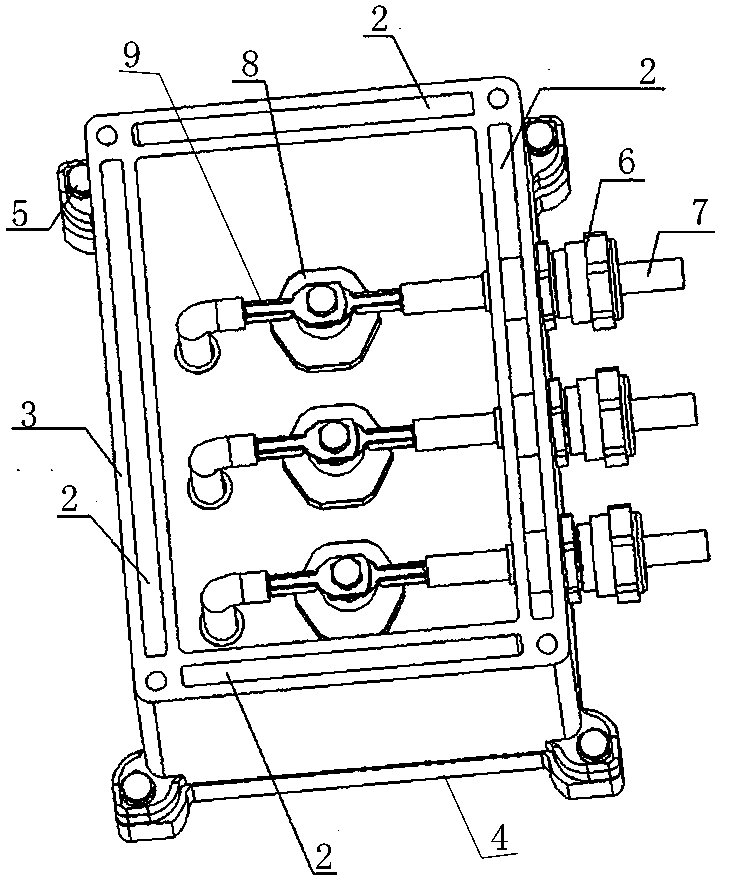

[0012] The electrical junction box to prevent condensation water is composed of a box body open on one side and a cover plate 1 that is sealed and fixed on the opening of the box body; the surrounding and bottom of the box body are hollow structures except for the perforated parts for cables to pass through (That is, the perforated part for the cable to pass through is a solid structure without a hollow structure); the cover plate 1 is a hollow structure; the hollow of the box body and the cover plate 1 is filled with heat insulating material 2 or vacuumized. In order to facilitate filling, during processing (welding or casting), the hollow of the cover plate 1 forms a single-sided opening, and the hollow of the box body forms a single-sided opening. After filling the heat insulating material 2 or vacuuming, the opening is welded and sealed or covered with sealant seal. The heat insulating material 2 uses a material with a thermal conductivity lower than that of metal.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com