Automatic wire stripping and terminal crimping machine

A technology of terminal punching and automatic wire stripping, applied in circuit/collector parts, electrical components, circuits, etc., can solve the problems that the motor cannot move intermittently and the cost of the servo motor is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further described in conjunction with the following examples.

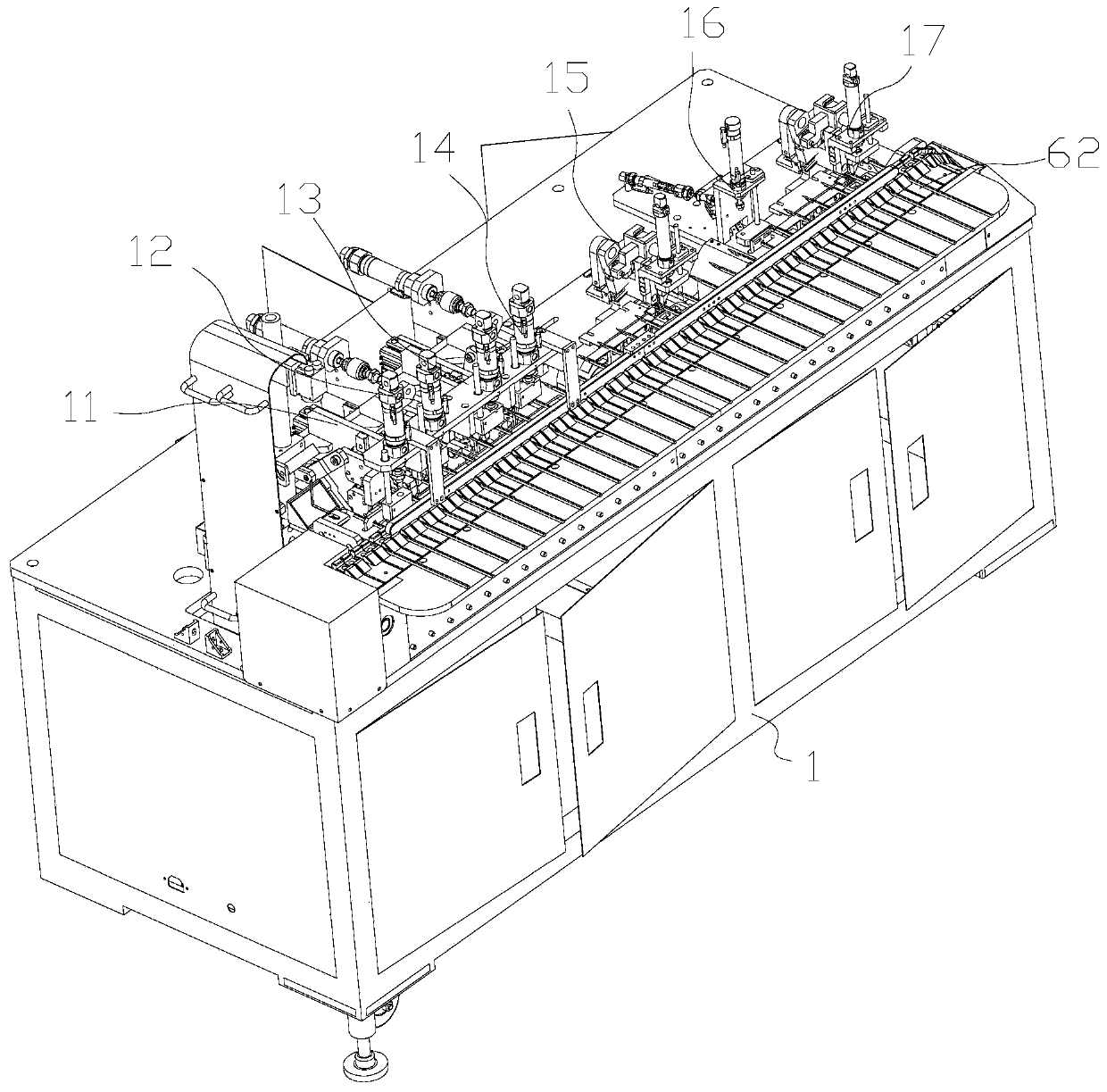

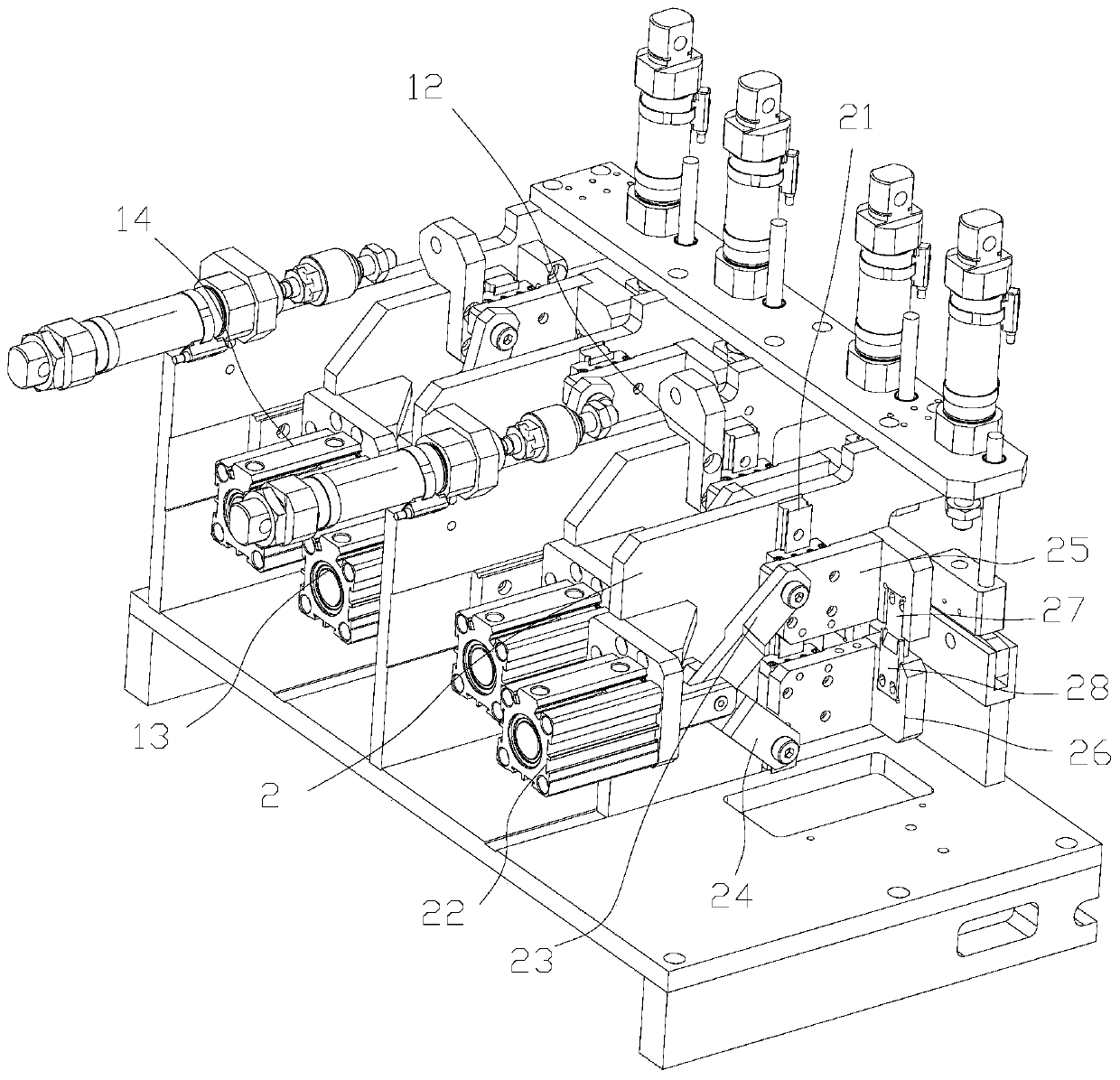

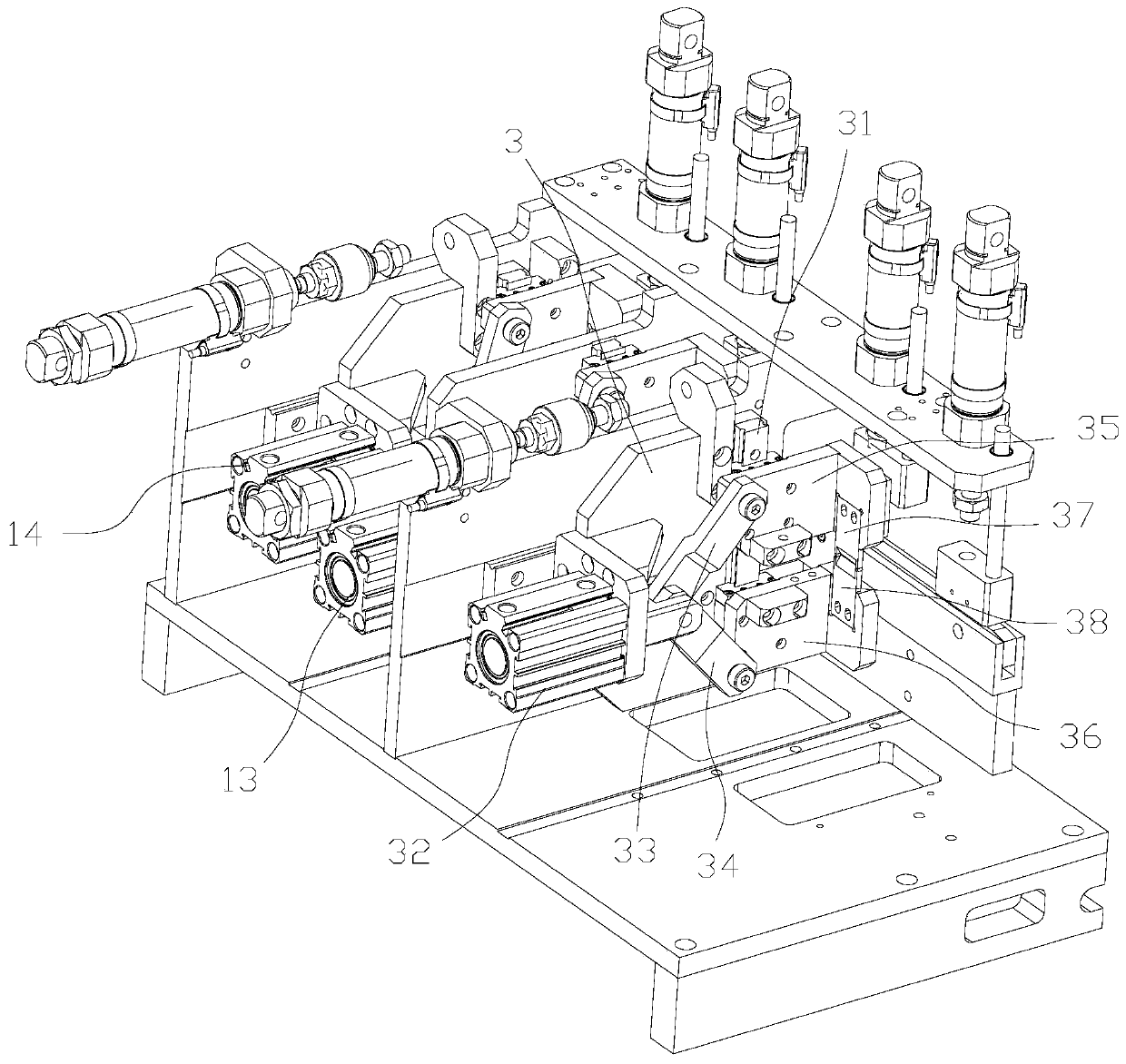

[0027] Depend on Figure 1 to Figure 9 It can be seen that a kind of automatic wire stripping and terminal punching machine described in this embodiment includes a machine table 1; a feeding mechanism is provided on the machine table 1; Cutting mechanism 11, first peeling mechanism 12, second cutting mechanism 13, second peeling mechanism 14, first terminal striking mechanism 15, branching mechanism 16 and second terminal striking mechanism 17;

[0028] The feeding mechanism includes a fixed base 61 arranged on the machine table 1, a first sprocket 611 rotatably connected to the fixed base 61, a second sprocket 612 rotatably connected to the fixed base 61, and sleeved between the first sprocket 611 and the fixed base 61. The chain 613 between the second sprockets 612 and the carrier 62 arranged on the material strip;

[0029] The feeding mechanism also includes a drive assembly fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com