Silicon-carbon-graphene electrode material of interlayer hollow double-shell structure and preparation method and application of silicon-carbon-graphene electrode material

A technology of graphene electrode and shell structure, which is applied in the direction of nanotechnology, negative electrode, and structural parts for materials and surface science, and can solve the problems of electrode material structure damage, electrode volume expansion, battery capacity attenuation, etc., and achieve preparation Low cost, excellent electrical conductivity, easy and stable control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

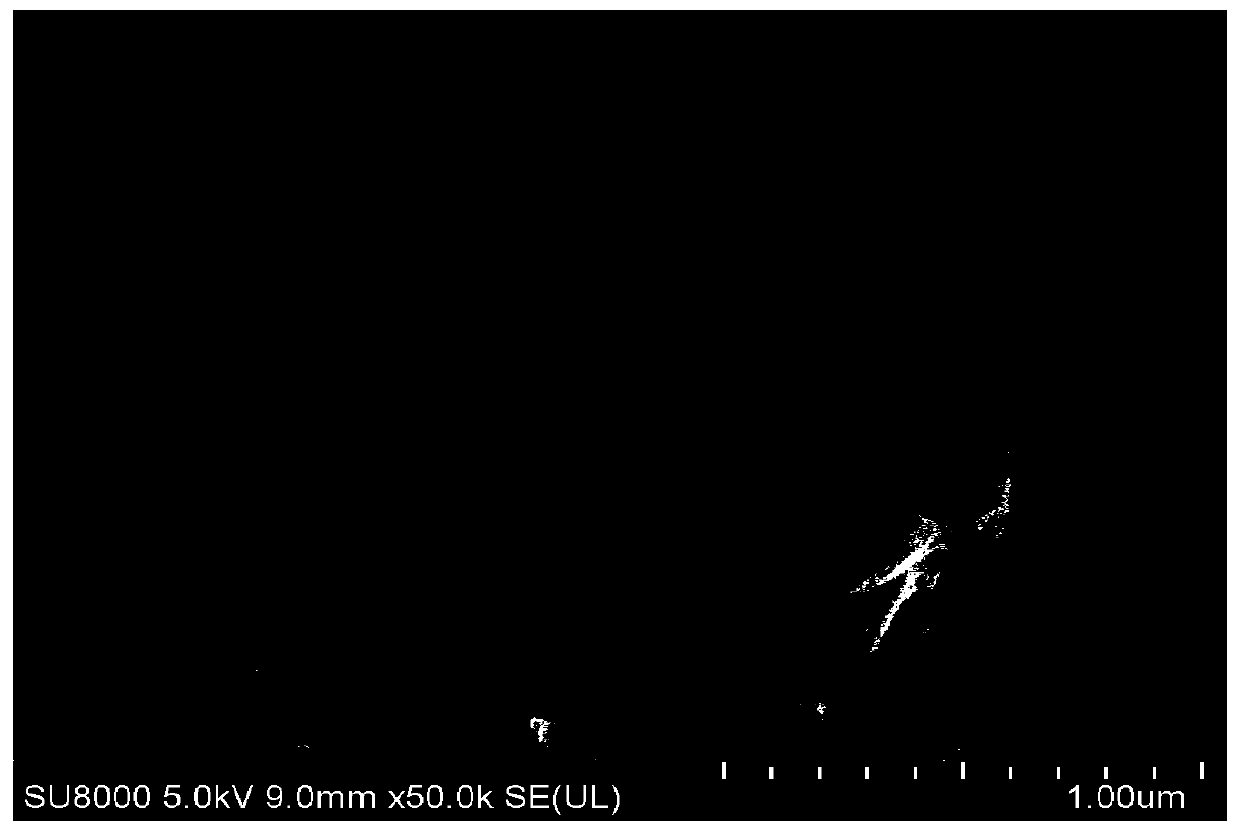

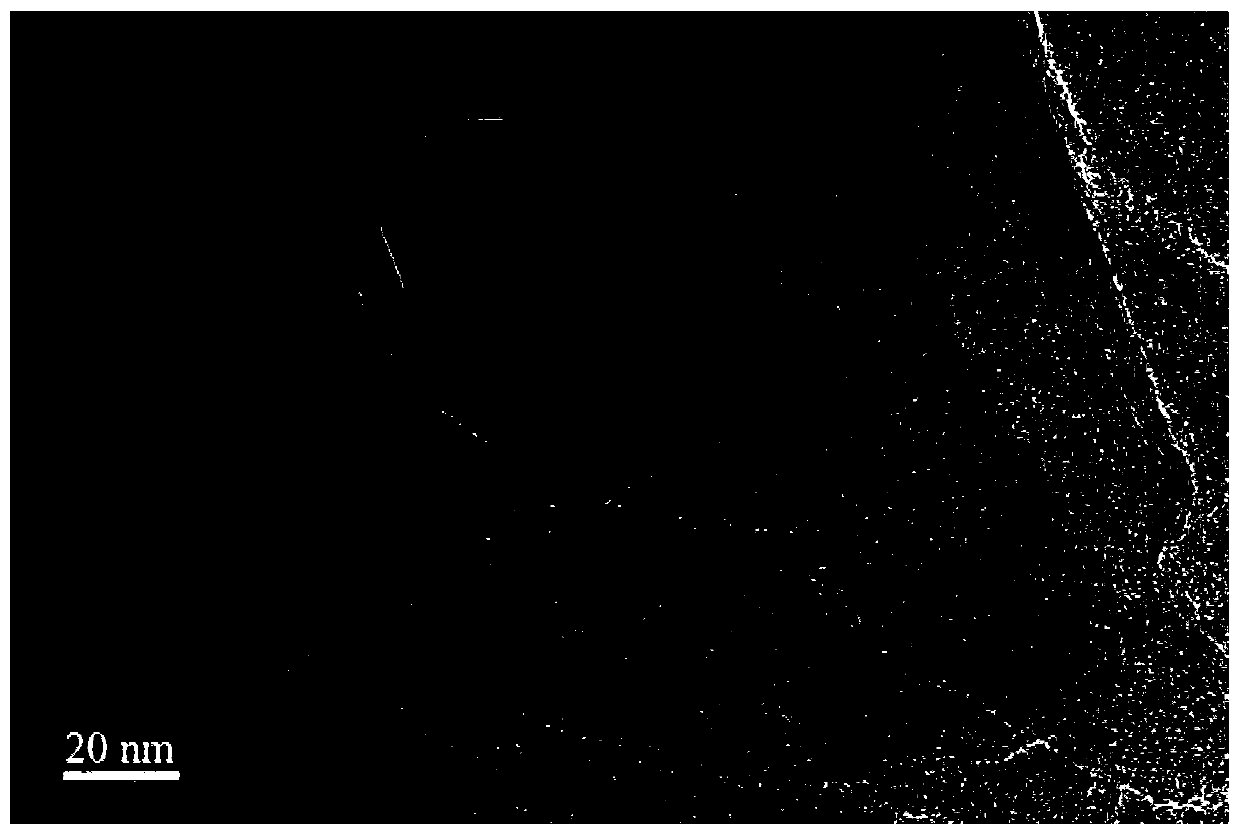

[0034] 1. Preparation of silicon-carbon-graphene electrode material with sandwich hollow double shell structure

[0035] (1) Weigh 0.15 g of commercial nano-silicon particles, wash and wash off the natural oxide layer on the nano-silicon surface by 10 wt% hydrofluoric acid solution, and then vacuum-dry at 80° C. to 120° C. for 8-10 hours.

[0036] (2) Put the obtained dry nano-silicon sample into a tubular calciner for high-temperature heat treatment, raise the temperature to 650-850°C at 5°C / min, and pass 60 sccm of Ar gas as a protective gas during the process. After reaching the temperature point, change to 60sccm compressed air and keep warm for 20 minutes. Then it was cooled with the furnace, and 60 sccm of Ar gas was used as the shielding gas. Finally, a sample with a certain thickness of oxide layer SiOx on the surface of silicon particles was obtained.

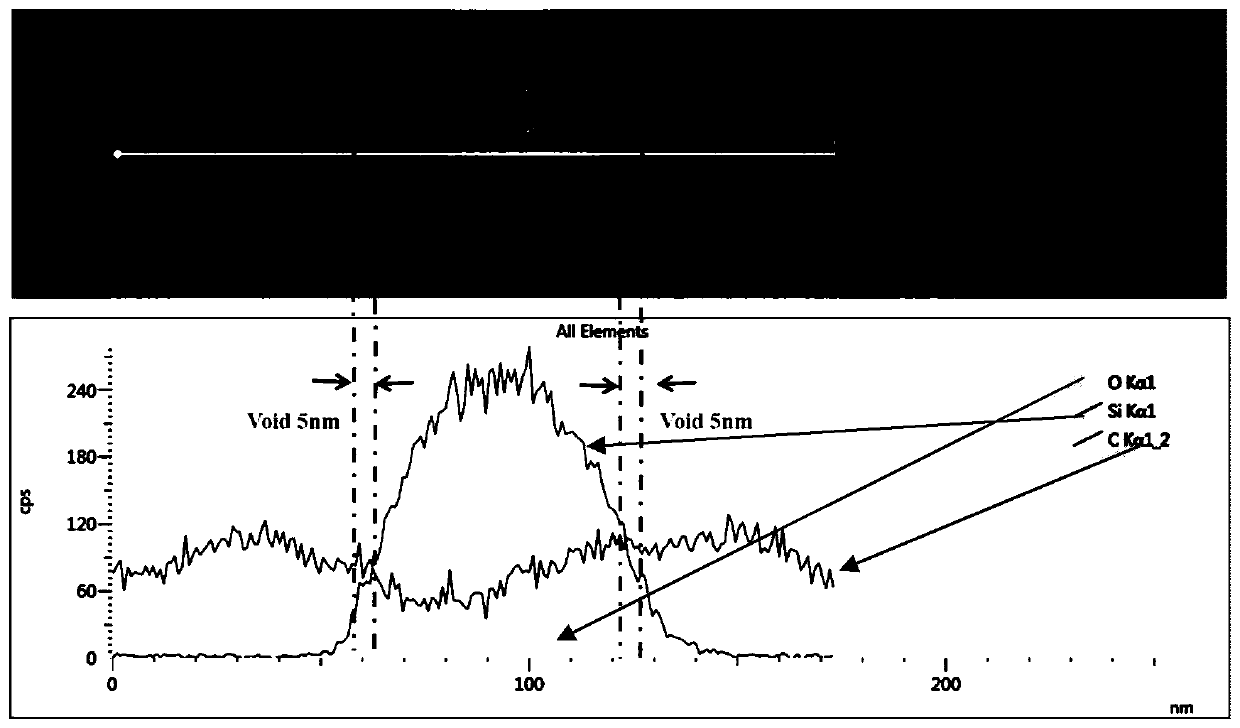

[0037] (3) Add 0.1 g of silicon particles treated in step (2) above to 150 ml of 5 g / L polydiallyldimethylammonium...

Embodiment 2

[0051] Repeat the (1)-(5) steps of the above-mentioned embodiment 1, and change the (3) step. Add 0.1 g of the above-mentioned silicon particles treated in step (2) into 150 ml of 10 g / L polydiallyldimethylammonium chloride solution, perform ultrasonic treatment for 30 min, and then centrifuge. When centrifuging, use 10000r / min and keep for 12min. Other conditions were kept the same, and the Si@SiOx-void(750)@C@C / rGO sample was finally obtained, and the battery test was as follows Figure 7 As shown, the capacity remained at 1050mAh / g after 100 cycles, which was lower than the Si@SiOx-void(750)@C / rGO sample, so the concentration of polydiallyldimethylammonium chloride solution was obtained by using 5g / L Sample results are best.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com