A built-in focusing electric water detection system and method mounted on a shield machine cutter head

A shield machine, focused technology, applied in the field of shield machine cutter head-built-in focused electric water detection system, can solve the problems of manpower and material resource consumption, no space for display, loss of surrounding personnel and buildings, etc. , to achieve the effect of making good use of space, ensuring accuracy and construction safety, and a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

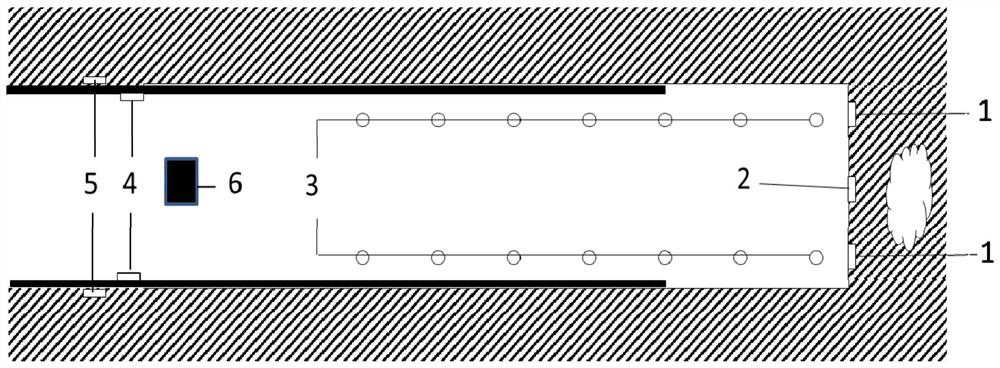

[0046] See attached figure 1 As shown, this embodiment discloses a built-in focused electrical water detection system mounted on the cutterhead of a shield machine, including a power supply electrode A01, a measurement electrode M2, a homogeneous source power supply electrode A13, an infinity power supply electrode B4, an infinity Measuring electrode N5, and excitation polarization detection instrument 6.

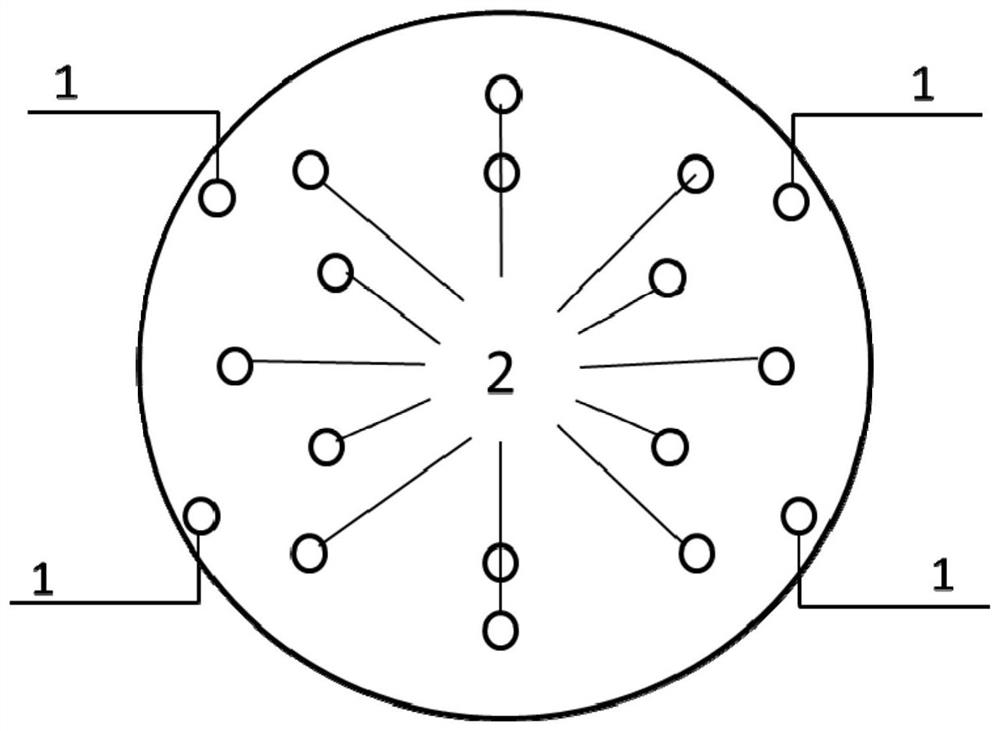

[0047] The layout position of the electrode system on the cutter head is as follows: figure 2 As shown, the built-in type is hidden in the cutterhead of the shield machine, following the principle of not destroying the original cutterhead structure and not affecting the use of the cutter.

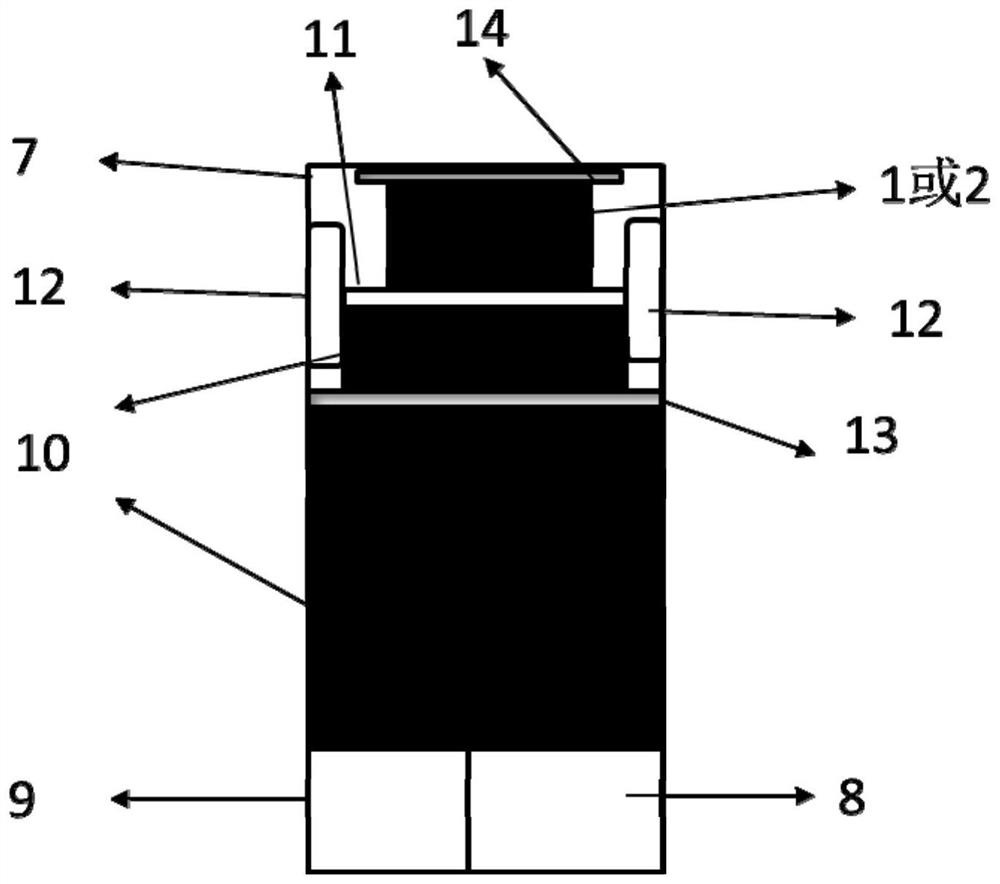

[0048] Among them, the power supply electrode A01 and the measuring electrode M2 are installed on the cutter head. After the shield machine starts construction, it is an area that cannot be reached by manpower frequently. In order to ensure the normal use and replacement of the instr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com