Fusion furnace for preparing plastic additives

A technology for the preparation of additives and plastics, applied in lighting and heating equipment, furnaces, incinerators, etc., can solve the problems of complex melting temperature control system, high cost, air pollution, etc., to increase the residence time, save costs, and increase heating efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

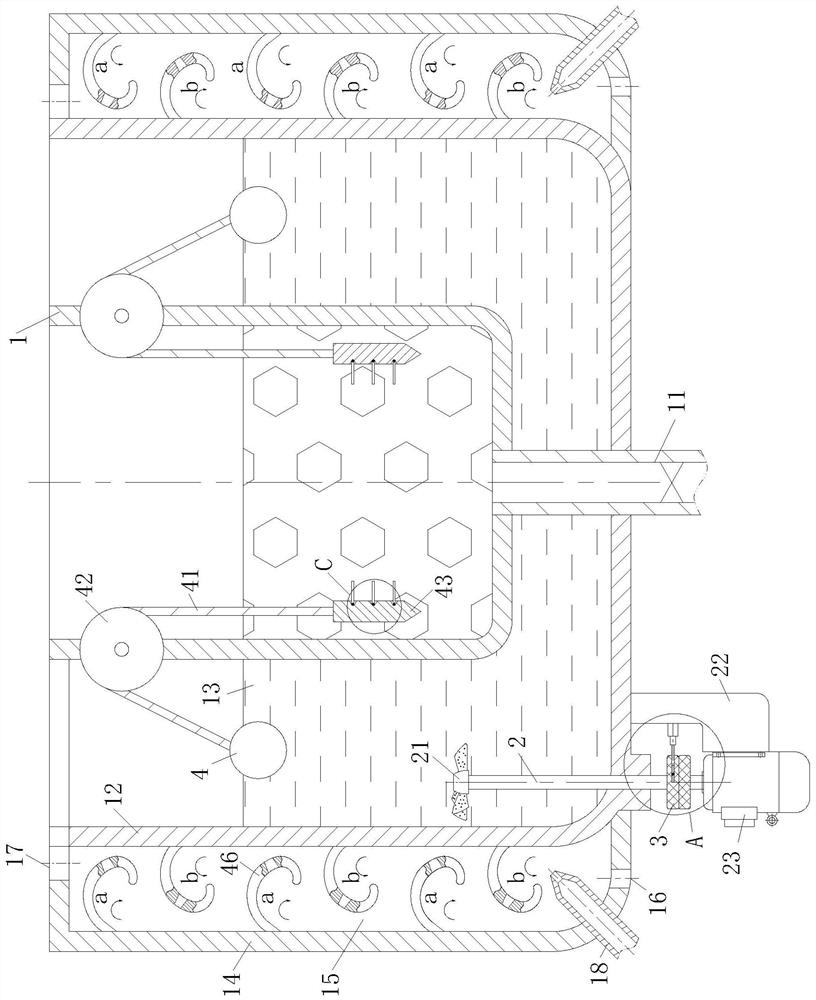

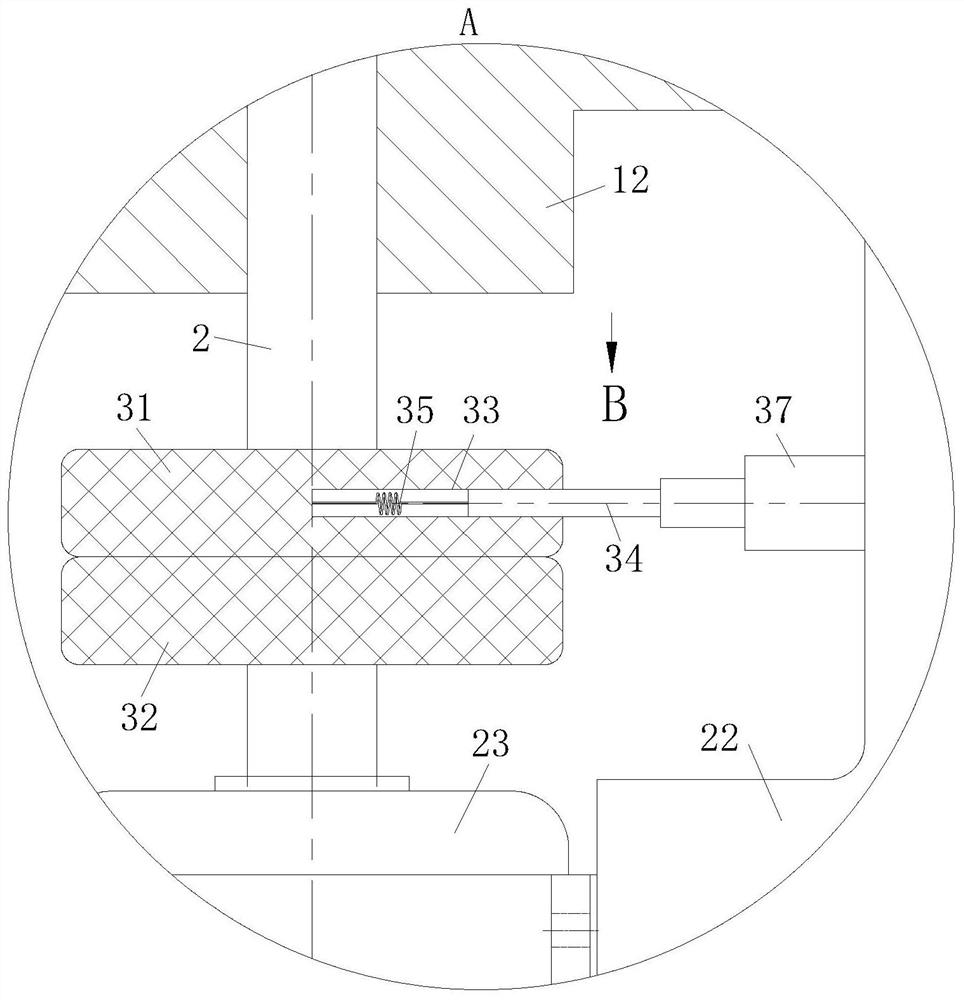

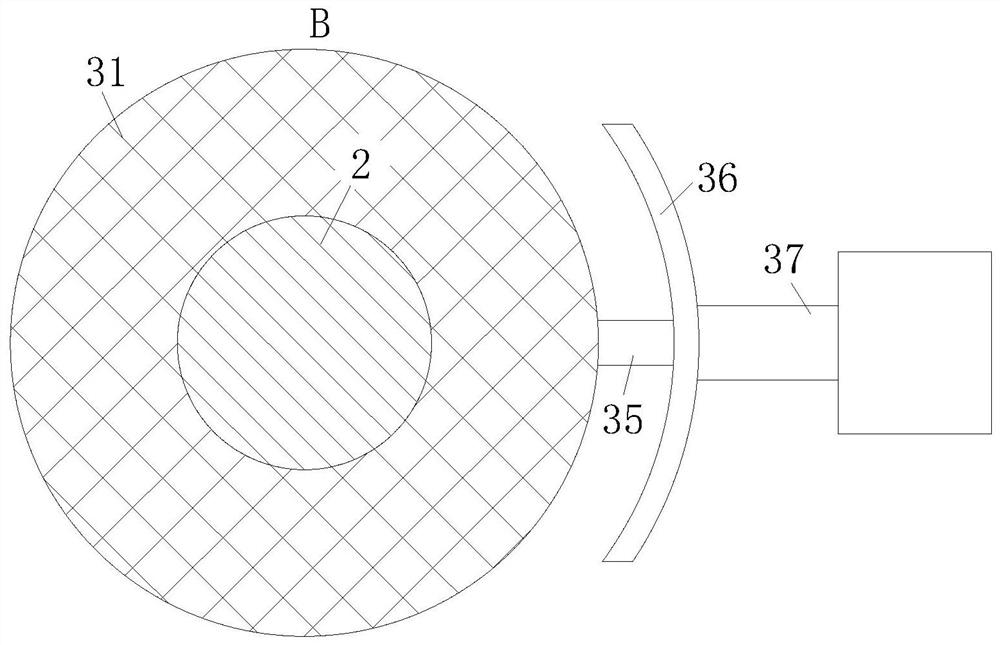

[0023] As an embodiment of the present invention, a No. 1 shaft 2 is rotatably connected to the water bath 13, and a water wheel 21 is fixedly connected to the top of the No. 1 shaft 2; the bottom of the No. 1 shaft 2 runs through a horn 12 and extends to a horn 12, and the No. 1 shaft 2 is in sliding and sealed connection with the No. 1 horn 12; the bottom of the No. 1 horn 12 and the corresponding position of No. 1 shaft 2 are fixedly connected with the motor 23 through the bracket 22, and the output shaft of the motor 23 is connected to the No. 1 horn through the control unit 3. The shaft 2 is connected; the motor 23 is connected to the power supply through the controller; the control unit 3 is used to control the opening and closing of the solenoid valve and the ignition of the gas nozzle 18; when the temperature of the paraben in the water bath 13 is lowered, it is triggered by the water wheel 21 The control unit 3 controls the gas nozzle 18 to spray gas to heat the water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com