Multistage axial flow compressor stability improvement structure based on sawtooth tailing edge blade

An axial flow compressor and sawtooth technology, applied in the field of aerodynamics, can solve the problems of compressor rotation stall, surge, compressor stall, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

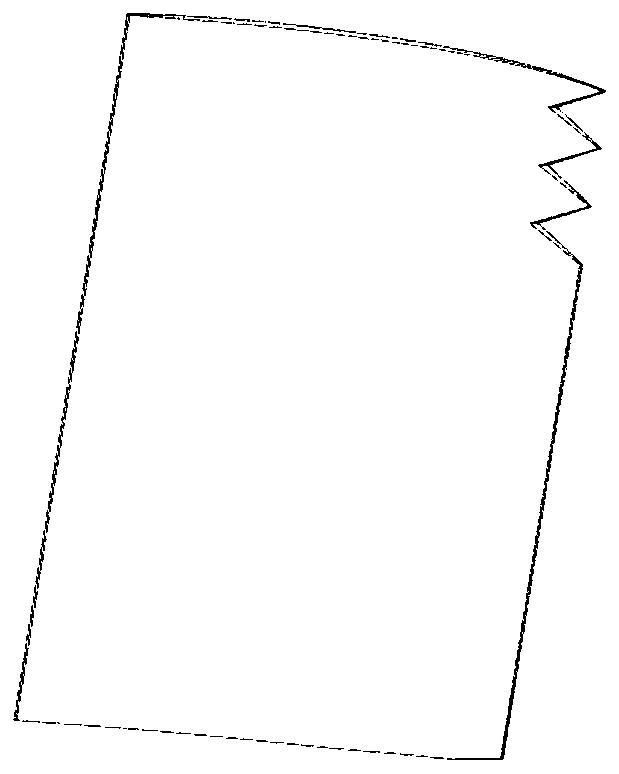

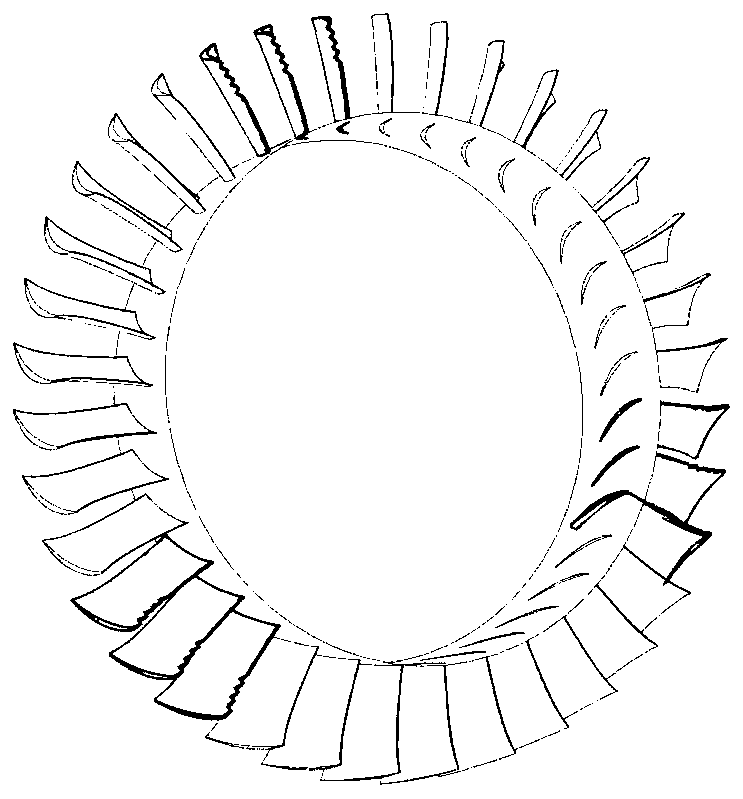

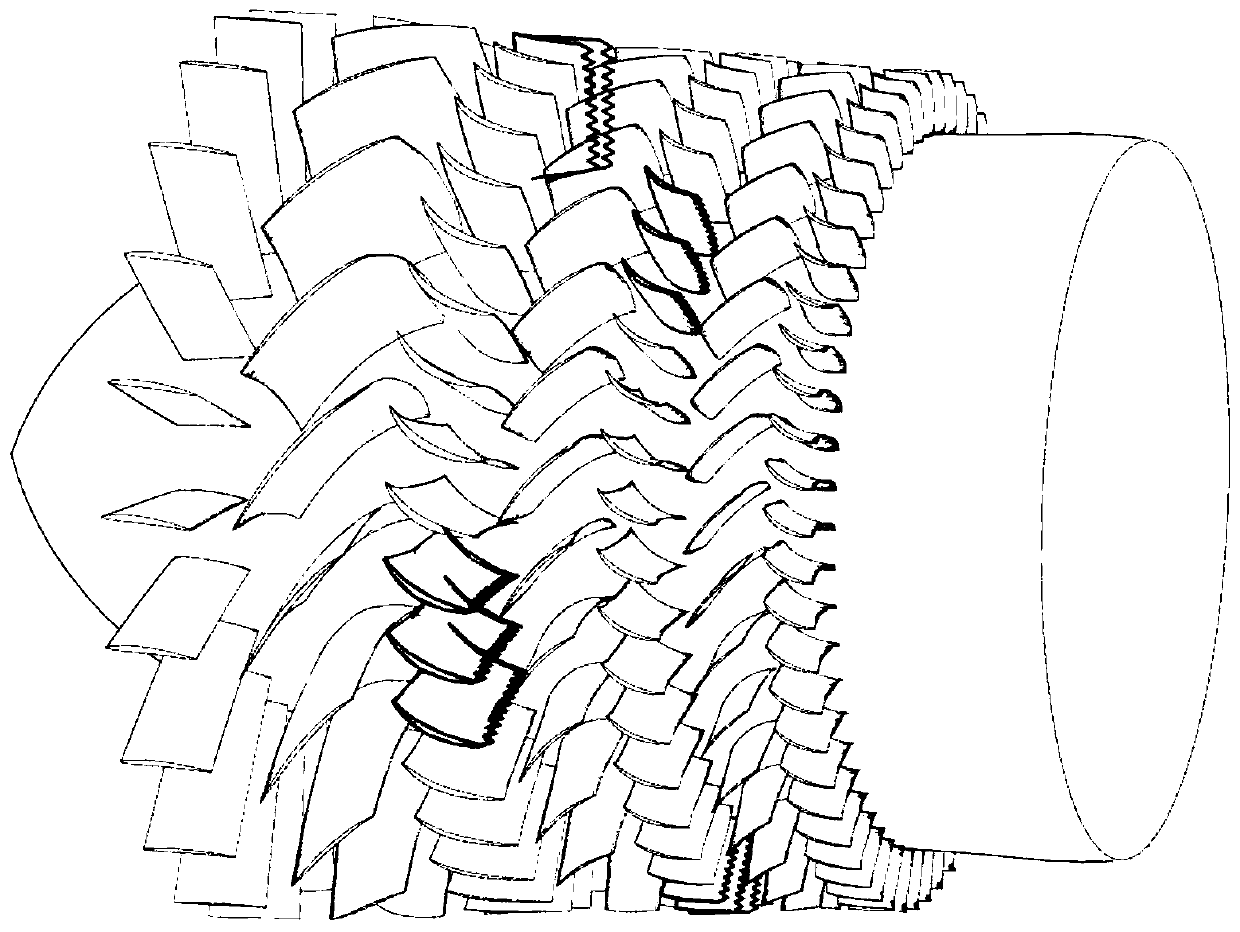

[0023] Due to the lack of a small piece in the chord length direction of the sawtooth trailing edge structure, it will inevitably weaken the processing pressurization capacity of this section. In order to reduce the performance of the multi-stage axial flow compressor as little as possible and widen the stable working range of the compressor, it is necessary to conduct experiments, numerical calculations, The stall characteristics of the axial flow compressor are obtained by technical means such as theoretical analysis. The aerodynamic stability expansion strategy of the sawtooth trailing edge blade is determined from the stall characteristics of the multi-stage axial flow compressor.

[0024] After obtaining the stalled primary stage or stalled primary blade row of a multi-stage axial flow compressor with insufficient stability margin, it is determined that the blade row upstream of the stalled primary stage or stalled primary blade row adopts serrated trailing edge blades; (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com