Preparation method and electret equipment of polypropylene melt-blown non-woven fabric

A technology of polypropylene melt-blown and non-woven fabrics, which is applied in the direction of liquid/gas/vapour removal by air jet method, non-woven fabrics, textiles and papermaking, etc., which can solve the problems of high risk factor, poor permeability of non-woven fabrics, electret It can improve the working environment, high filtering effect and stable electret

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

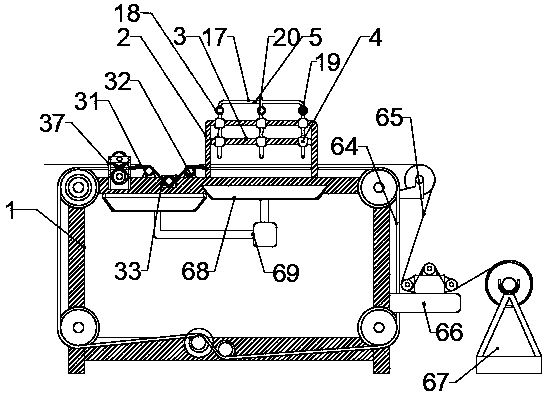

[0037] The present invention will be further described below in conjunction with specific embodiment:

[0038] A preparation method of polypropylene melt-blown non-woven fabric, specifically comprising the following steps;

[0039] Step 1, melt blown production; select polypropylene granules as the raw material, transport the polypropylene granule raw material to the extruder, the raw material extruded by the extruder is sprayed out through the touch spinneret, the airflow generated by the air compressor and the spraying of the raw material The output direction is the same, the air heater heats the airflow generated by the air compressor, the receiving roller receives the raw material ejected from the spinneret, and the receiving roller receives it to form a non-woven fabric;

[0040] Step 2, pure water preparation; choose tap water as the water source, filter the water source with sand and gravel tanks and activated carbon tanks, add reverse osmosis agent and hydrochloric acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com