A kind of alkali-free high aluminum borosilicate glass and its preparation method

A silicate glass and high-alumina-boron technology, which is applied in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve the problems of alkali-free high-alumina borosilicate glass clarification difficulties, environmental pollution, and poor uniformity. Achieve the effects of increasing the clarification temperature range, reducing the thermal expansion coefficient, and good clarification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

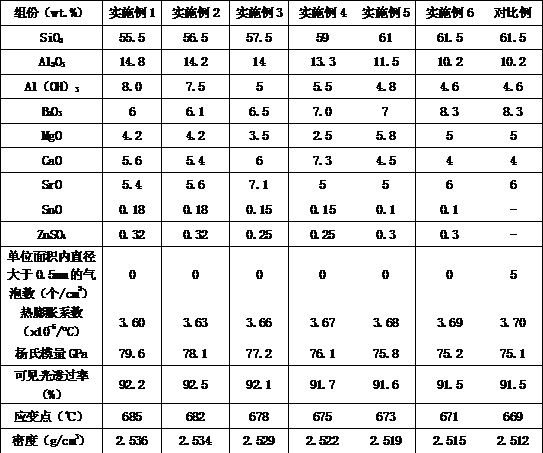

[0025] The specific embodiments of the present invention will be described in detail below, and the specific embodiments described here are only used to illustrate and explain the present invention, but not to limit the present invention.

[0026] One, a kind of alkali-free high alumina borate glass provided by the present invention is made of the following raw materials in weight percentage:

[0027] SiO 2 54.5~63.5%

[0028] al 2 o 3 10~15%

[0029] Al(OH) 3 4.5~9.5%

[0030] CaO 3~15%

[0031] B 2 o 3 6~13%

[0032] MgO 2~9%

[0033] SrO 5~10%

[0034] SnO 0.05~0.3%

[0035] ZnSO 4 0.1~0.35%

[0036] Two, the preparation method of a kind of alkali-free high alumina borate glass provided by the present invention comprises the following steps:

[0037] 1) Weigh the above-mentioned various raw materials according to the above-mentioned weight percentages, and mix them uniformly through the mixing system to obtain glass batch materials;

[0038] 2) Melt the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strain point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com