Novel fixed-scale cutting device for PVC plastic floors

A plastic floor and cutting device technology, applied in the direction of metal processing, etc., can solve the problems of lack of limit cutting, poor effect of debris cleaning, lack of cleaning and collection, etc., to increase the cleaning function and facilitate cleaning The effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

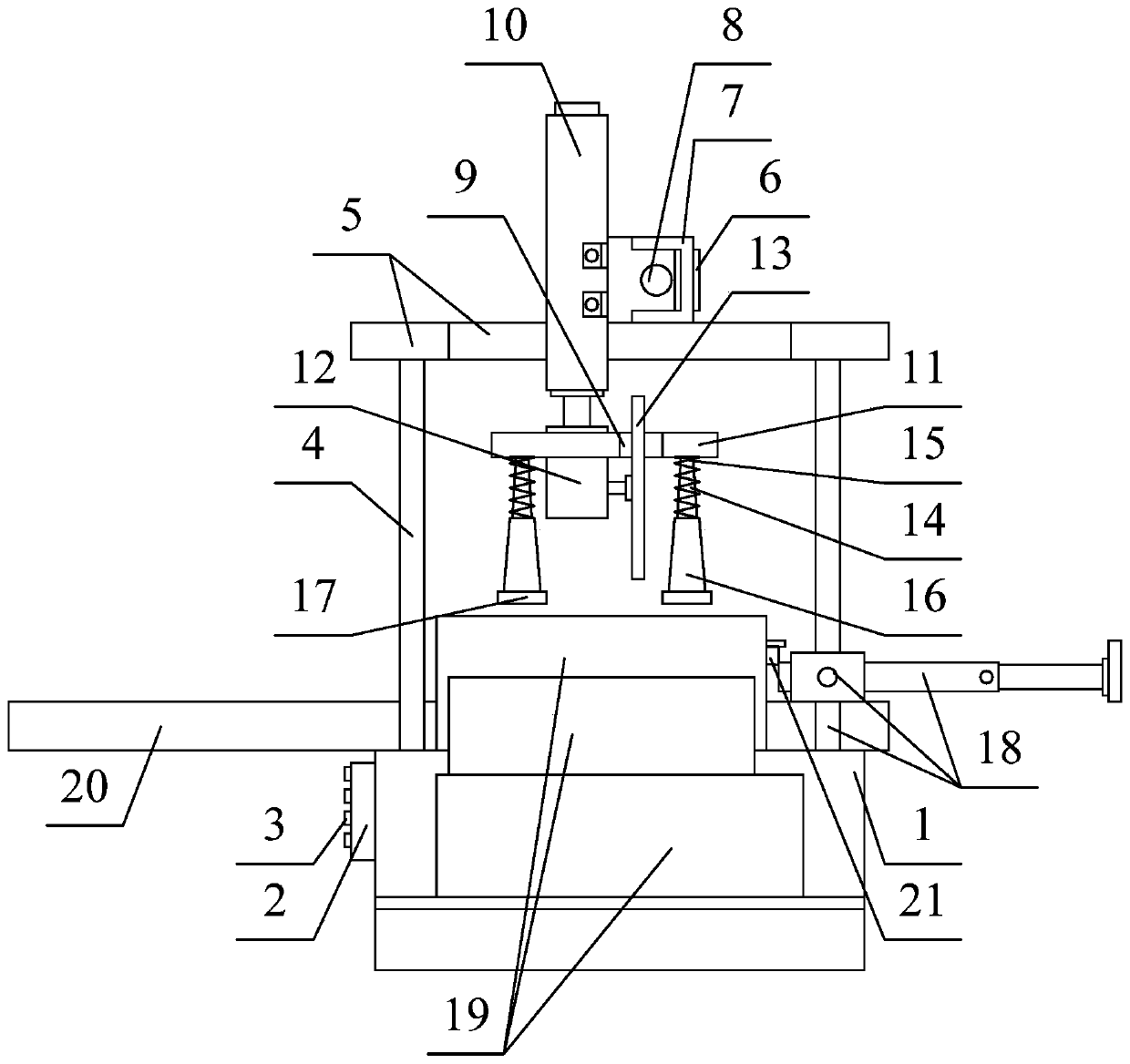

[0033] The present invention will be further described below in conjunction with accompanying drawing:

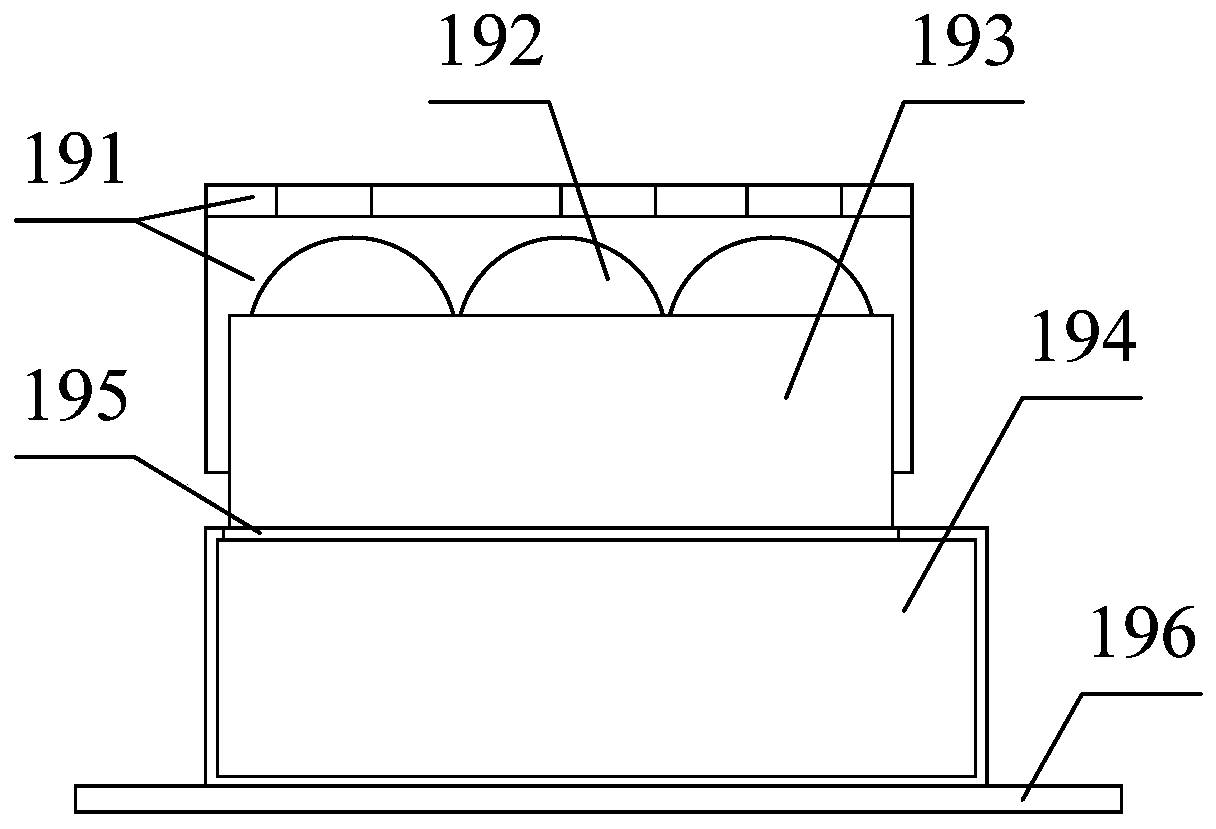

[0034] as attached figure 1 And attached figure 2As shown, a novel PVC plastic floor cutting device according to the present invention includes a base 1, a PLC 2, a switch 3, a pole 4, a roof frame 5, a conveying motor 6, a base 7, and a ball screw pair 8 , through hole 9, lowering cylinder 10, connecting plate 11, cutting motor 12, cutting blade 13, inserting rod 14, clamping spring 15, sleeve 16, lower pressure plate 17, auxiliary limit adjustment frame structure 18, auxiliary The suction box frame structure 19, the conveying mechanism 20 and the cleaning plate frame structure 21, the bolts of the PLC2 are installed on the upper part of the left surface of the base 1; the switch 3 is embedded in the left surface of the PLC2; the pole 4 is welded At the four corners of the upper surface of the base 1; the top plate frame 5 is welded on the upper end of the pole 4; the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com