Method for reducing grinding frequency of aluminum alloy spot welding electrode

A technology for spot welding electrodes and aluminum alloys, applied in electrode characteristics, electrode maintenance, etc., can solve the problems of high grinding frequency, low production cycle, and high electrode consumption, so as to reduce the grinding frequency, ensure production cycle, and ensure welding quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

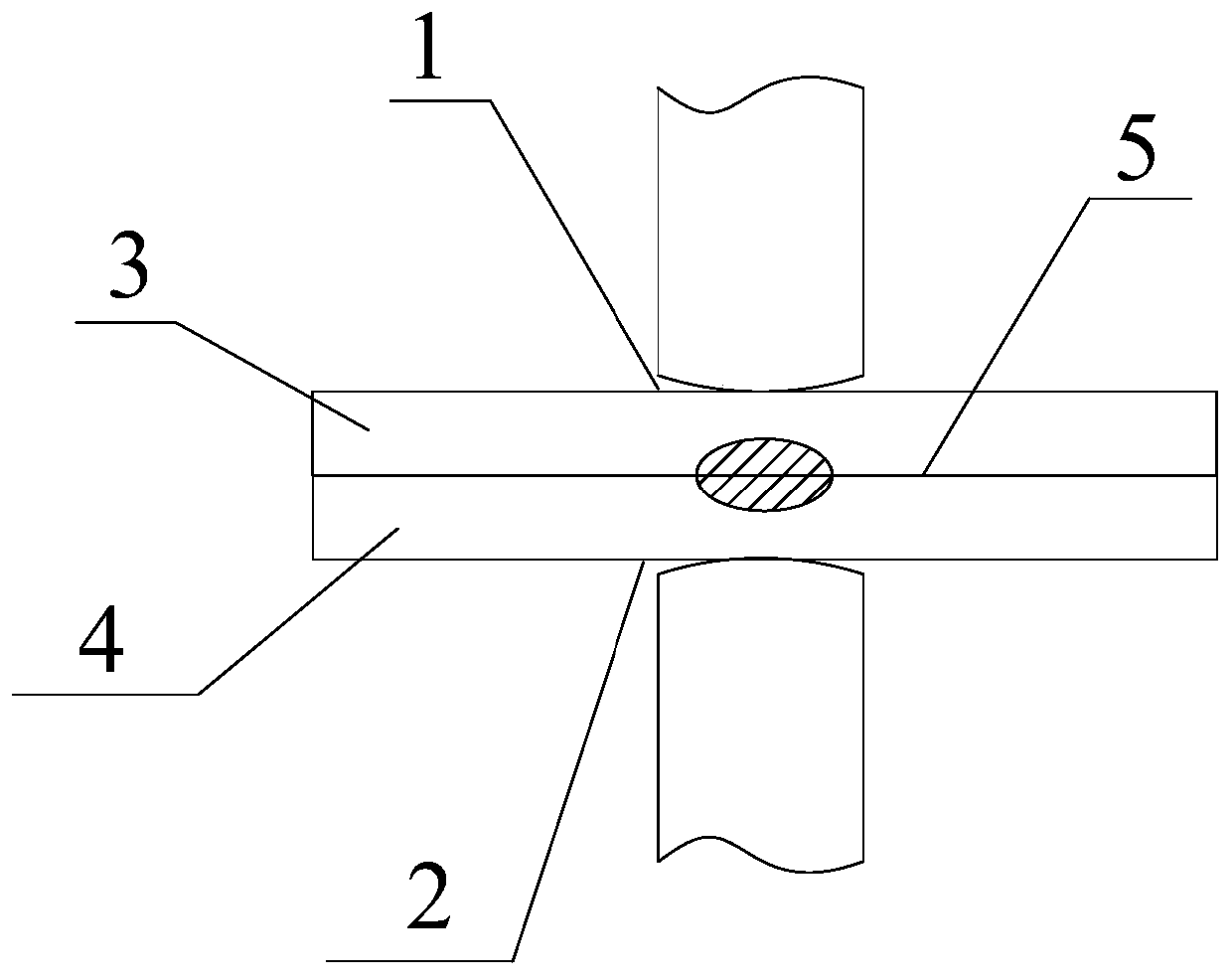

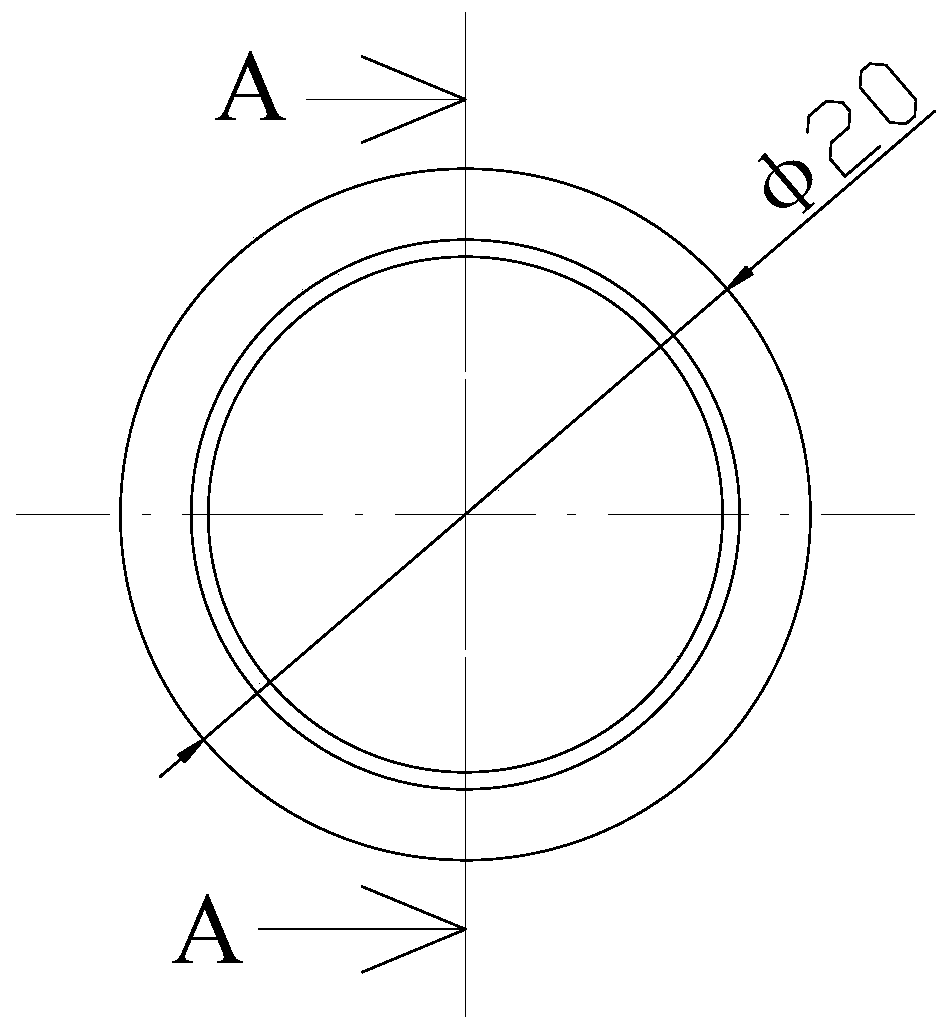

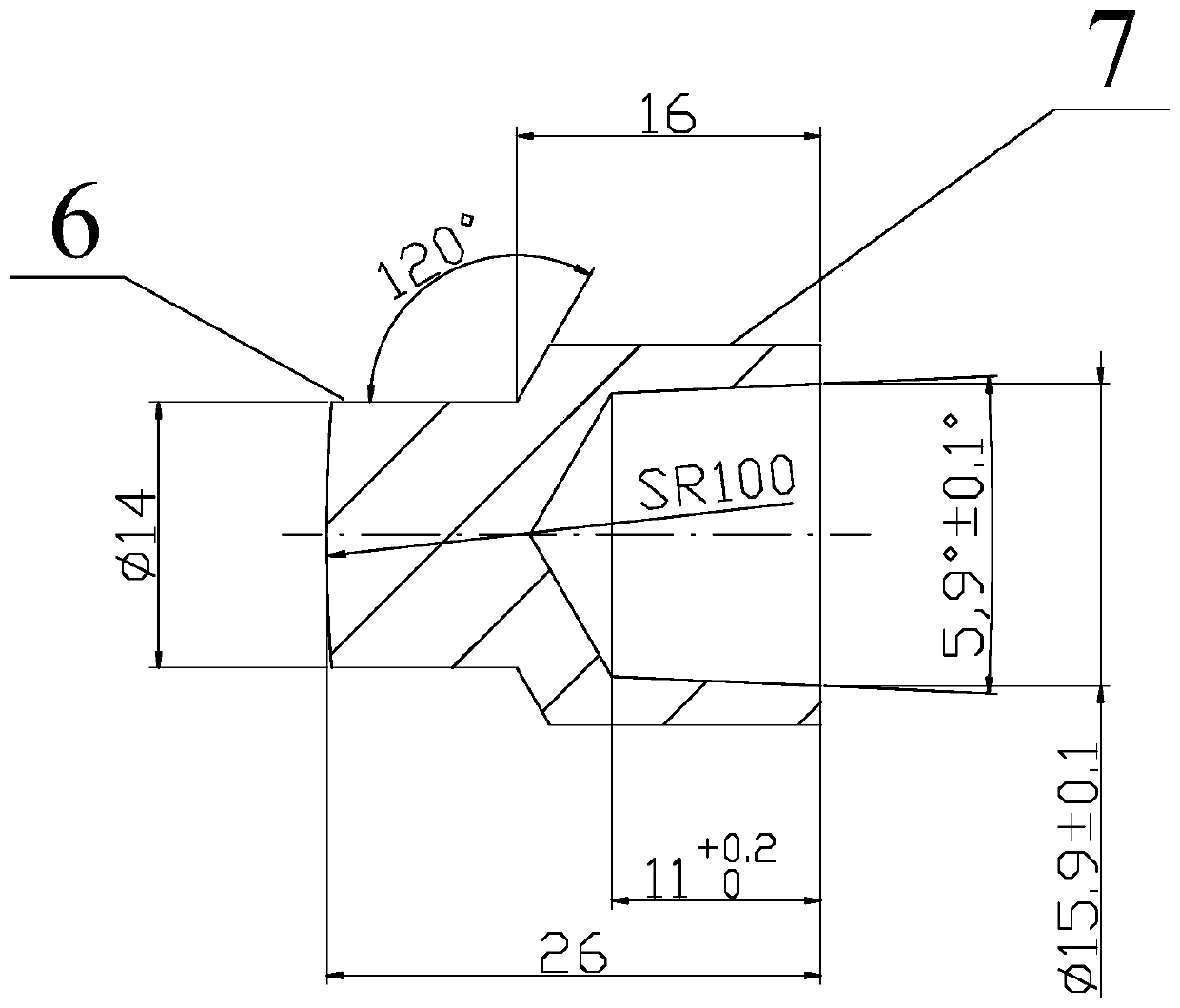

[0021] The invention aims to solve the problems of rapid electrode wear and high grinding frequency in aluminum alloy welding, resulting in low production beat and high electrode consumption. This method is applicable to the aluminum alloy resistance spot welding process, and the principle and improvement means of this method will be discussed below.

[0022] The research shows that the serious burning of the aluminum alloy spot welding electrode is mainly due to the aluminum-copper alloy reaction between the copper electrode and the aluminum alloy workpiece surface due to electric heating during the entire welding cycle, resulting in adhesion, and the electrode end surface becomes uneven, even...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com